Method for bored pile construction in high-latitude and extremely-cold permafrost region

A bored pile and alpine technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of few pile foundation construction schemes, no irrigation drilling method, permafrost hole collapse and pile foundation damage. and other problems, to achieve the effect of convenient transportation, entry and transfer, improved drilling efficiency, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

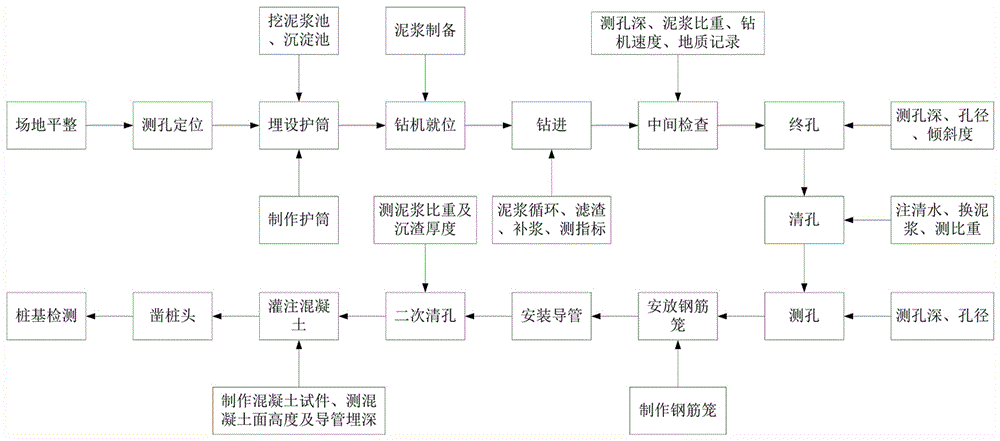

[0052] This embodiment discloses a construction method of bored piles in high-position, high-cold permafrost regions, such as figure 1 As shown, it is mainly to overcome the problem of frost heave damage to the pile foundation caused by moisture migration in the permafrost in high-latitude alpine regions, not only to prevent hole collapse and pile foundation damage due to uneven stress through various construction schemes In the case of percussion drilling, various plans are used to drill for different geological layers to ensure the construction efficiency and make the hole wall strong and stable. The specific implementation of the construction method is as follows:

[0053] 1. Construction preparation:

[0054] First of all, construction preparations must be carried out before construction, leveling the site in the construction area, removing debris, and compacting the drilling rig position. Unified arrangements shall be made for processing sites and construction access ro...

Embodiment 2

[0093] This embodiment is further defined on the basis of the above-mentioned embodiments. If construction is carried out in winter, some improvements should be made to the construction plan.

[0094] As temperatures cool, the seasonally frozen ground above the permafrost begins to freeze down to the surface. At this time, a section of 1.5m casing is buried to ensure that the mud overflow is higher than the construction water level, and then the percussion drilling construction can be started. During the construction, hollow slag drill bit is used to drill with a medium stroke of 75cm, and mud with a relative density of 1.25~1.5 is used to protect the wall to ensure the continuity of construction and prevent the phenomenon of drill sticking caused by freezing of water and mud. During the construction process, the specific gravity of the mud can be adjusted appropriately. At this time, the mud in the hole not only plays the role of wall protection, but also plays the role of h...

Embodiment 3

[0097] The present embodiment is further defined on the basis of the foregoing embodiments. The present embodiment is to apply the construction method of the present invention to a relatively large bridge construction project. The whole project builds 4 extra-large bridges and two large bridges. There are 640 pile foundations with a length of 10,053 meters, all of which are constructed by percussion drilling. From the start of work in August 2009 to the completion of pile foundation construction in August 2010, all of them are class I and class II piles after small strain tests, and class I piles 590, reaching 92%, the quality of piles is excellent. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com