Novel flexible array pressure sensor

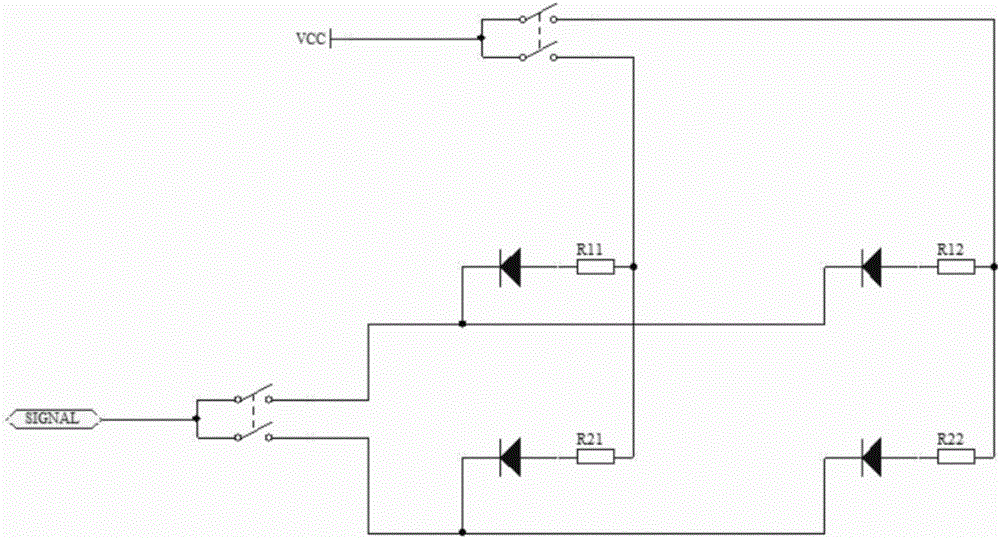

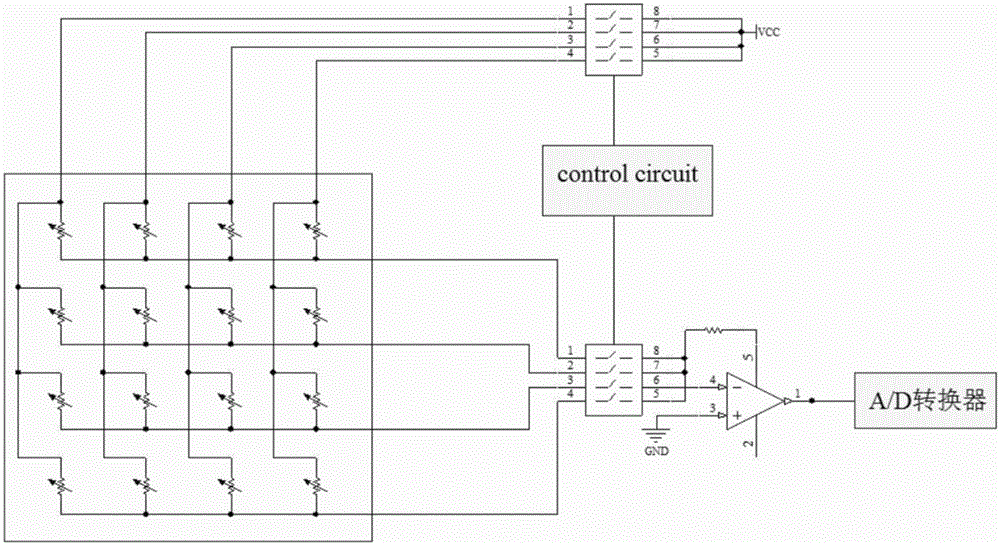

A pressure sensor and flexible array technology, applied in the field of sensor structure design, can solve the problems of eliminating cross-coupling, complex circuits, complex conditioning circuits, etc., to achieve the effect of eliminating cross-coupling and eliminating cross-coupling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

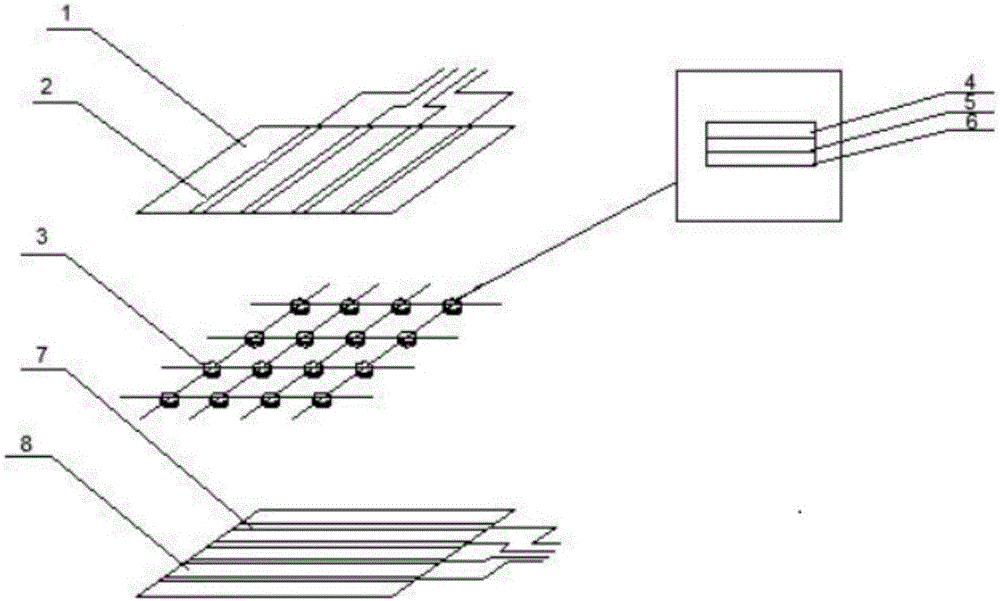

[0041] The upper and lower flexible film layers of the flexible array pressure sensor of this embodiment are polyimide films; the upper and lower electrode layers are silver, obtained by screen printing; the pressure sensitive unit 3 includes a stacked three-layer structure, From top to bottom are a 30 μm thick conductive rubber pressure-sensitive film 4 , a 30 μm thick p-type gallium nitride film 5 and a 30 μm thick n-type gallium nitride film 6 .

[0042] The preparation method of the flexible array pressure sensor described in the embodiment specifically includes the following steps:

[0043] Step 1: Take two pieces of PI (polyimide) film materials with the same shape and size as the upper and lower flexible film layers respectively, clean the surface with deionized water for 10 minutes, and dry under a nitrogen atmosphere;

[0044] Step 2: Put the two pieces of PI films cleaned in step 1 on the printing table of the screen printing machine respectively, and then print the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com