Two-dimensional layered nitrogen-doped Ti<3>C<2> ''paper'' nanocomposite and preparation method therefor, and method for preparing composite electrode by employing nanocomposite

A nano-composite material, two-dimensional layered technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing and other directions, can solve problems such as low specific capacitance, and achieve the effects of expanding layer spacing, improving utilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

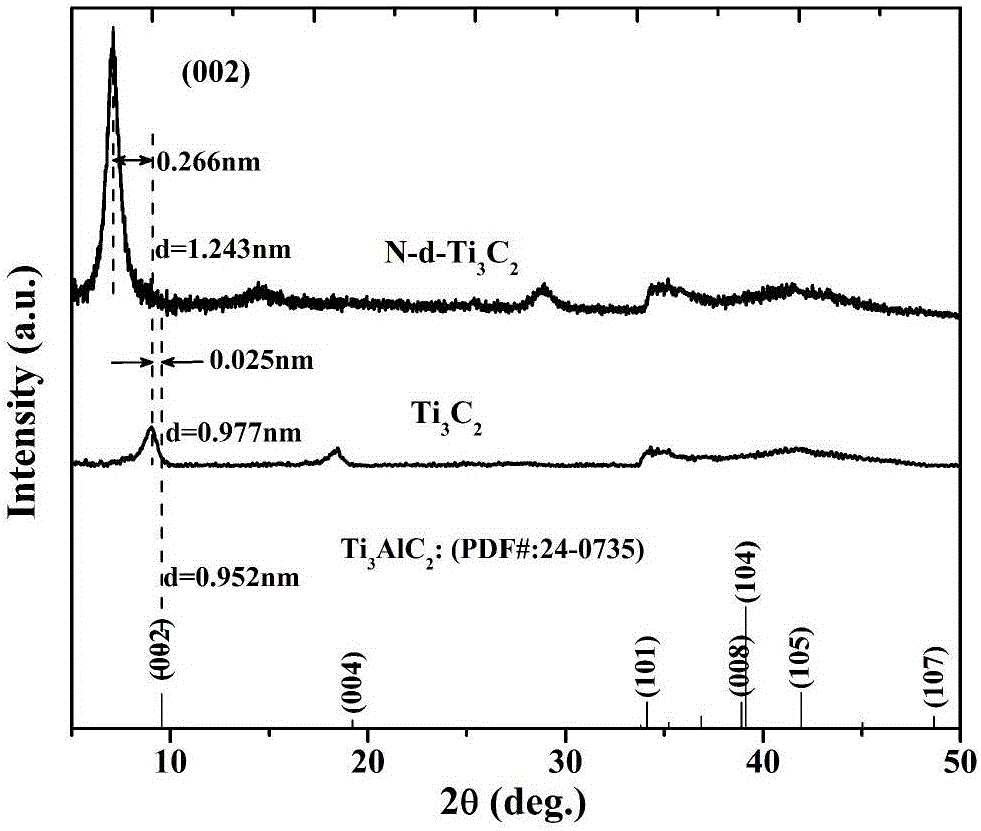

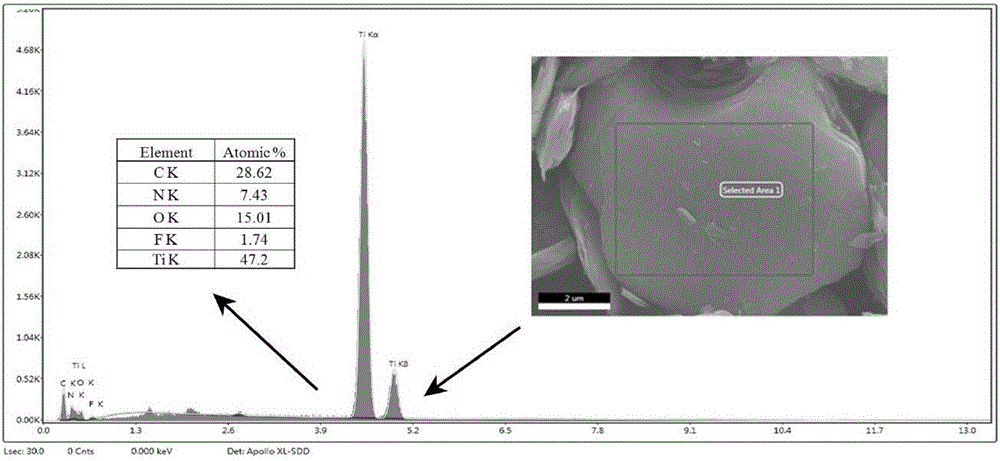

[0030] Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites involves:

[0031] Step 1: Two-dimensional layered Ti 3 C 2 Preparation of nanomaterials;

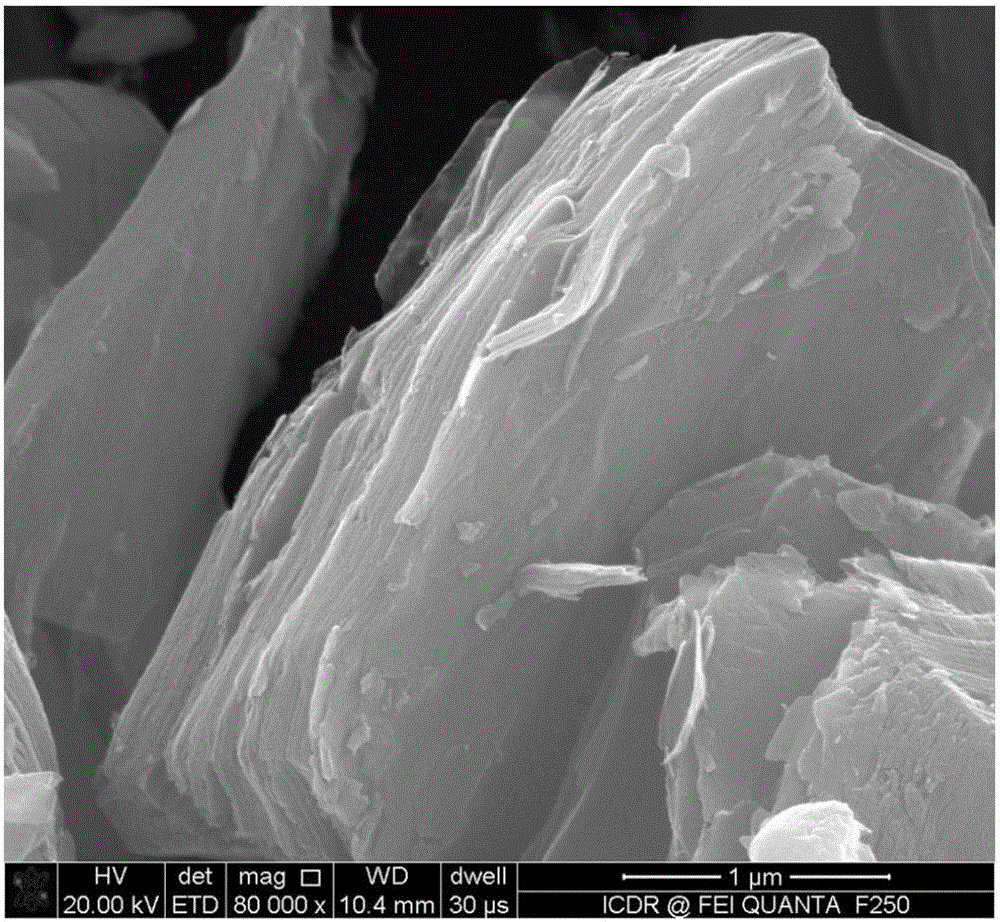

[0032] Synthesize two-dimensional layered Ti according to the method of patent 201410812056.7 3 C 2 nanomaterials;

[0033] Step 2: Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites;

[0034] First, take 300mg of Ti from Step 2 3 C 2 Add the nano-powder to 10 g of urea aqueous solution with a mass concentration of 50%, and stir evenly at 60°C;

[0035] Then, add ultrapure water to dilute to Ti 3 C 2 500 times the mass, with a frequency of 60Hz, ultrasonic dispersion for 6h;

[0036] Secondly, centrifuge and wash with ultrapure water and absolute ethanol, centrifuge at 5000rpm for 4min each time to obtain separated solids, and dry them in vacuum at 80°C to obtain two-dimensional layered Ti 3 C 2 "Paper" nanomaterials;

[0037] Again, put Ti 3 ...

Embodiment 2

[0046] Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites involves:

[0047] Step 1: Two-dimensional layered Ti 3 C 2 Preparation of nanomaterials;

[0048] Synthesize two-dimensional layered Ti according to the method of patent 201410812056.7 3 C 2 nanomaterials;

[0049] Step 2: Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites;

[0050] First, take 1000mg of Ti from step 2 3 C 2 The nano-powder is added to 30 g of urea aqueous solution with a mass concentration of 50%, and stirred evenly at 50°C;

[0051] Then, add ultrapure water to dilute to Ti 3 C 2 300 times the mass, with a frequency of 40Hz, ultrasonic dispersion for 4h;

[0052] Secondly, centrifuge and wash with ultrapure water and absolute ethanol, centrifuge at 7000rpm for 3min each time to obtain separated solids, and dry them in vacuum at 60°C to obtain two-dimensional layered Ti 3 C 2 "Paper" nanomaterials;

[0053] Again, p...

Embodiment 3

[0061] Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites involves:

[0062] Step 1: Two-dimensional layered Ti 3 C 2 Preparation of nanomaterials;

[0063] Synthesize two-dimensional layered Ti according to the method of patent 201410812056.7 3 C 2 nanomaterials;

[0064] Step 2: Two-dimensional layered nitrogen-doped Ti 3 C 2 Preparation of "paper" nanocomposites;

[0065] First, take 1800mg of Ti from Step 2 3 C 2 The nano-powder is added to 50 g of urea aqueous solution with a mass concentration of 50%, and stirred evenly at 70°C;

[0066] Then, add ultrapure water to dilute to Ti 3 C 2 700 times the mass, with a frequency of 80Hz, ultrasonic dispersion for 5h;

[0067] Secondly, centrifuge and wash with ultrapure water and absolute ethanol, centrifuge at 4000rpm for 4min each time to obtain separated solids, and dry them in vacuum at 120°C to obtain two-dimensional layered Ti 3 C 2 "Paper" nanomaterials;

[0068] Again, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com