Preparation method of composite polymer electrolyte and lithium secondary battery

A technology of composite polymer and sulfide electrolyte, applied in the field of preparation of composite polymer electrolyte, can solve the problems of high cost, insufficiently uniform composite with polymer, complicated sulfide electrolyte process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention discloses a method for preparing a composite polymer electrolyte, comprising the following steps:

[0034] A), mixing the polymer matrix, the alkali metal salt and the solvent to obtain a mixed solution; mixing the sulfide electrolyte raw material with the solvent, heating and stirring, and obtaining a sulfide electrolyte precursor slurry after the reaction;

[0035] B), mixing the mixed solution with the material to obtain a composite electrolyte solution;

[0036] C), drying the composite electrolyte solution and then heat-treating to obtain a composite polymer electrolyte;

[0037] The general formula of the sulfide electrolyte in the sulfide electrolyte precursor slurry is one or more of formula (I) and formula (II);

[0038] (100-a-b)Li 2 S·aP 2 S 5 bM (I);

[0039] Among them, 02 o 5 , Li 3 PO 4 , LiO 2 , SiO 2 , Fe 2 o 3 , ZrO 2 , ZnO, TiO 2 , La 2 o 3 , Nb 2 o 5 and GeO 2 one or more of

[0040] (100-y)[(...

Embodiment 1

[0058] Under the protection of argon atmosphere, after weighing PEO and LiTFSI according to the EO / Li molar ratio of 18:1, stir in acetonitrile to obtain solution A; 2 S and P 2 S 5 According to the molar ratio of 70:30, it is weighed and added into acetonitrile, stirred evenly at 50°C to obtain 70Li 2 S·30P 2 S 5 Slurry B; according to 70Li 2 S·30P 2 S 5 Accounting for 1% of the total mass of the composite polyelectrolyte, mix solution A and slurry B, and obtain solution C after stirring evenly; cast the solution C to be cast into a molding mold, place it at 40°C for 24 hours, let the solvent volatilize, and then place Heat treatment at 250° C. for 0.5 h in a muffle furnace to completely volatilize the solvent to obtain a composite polymer electrolyte.

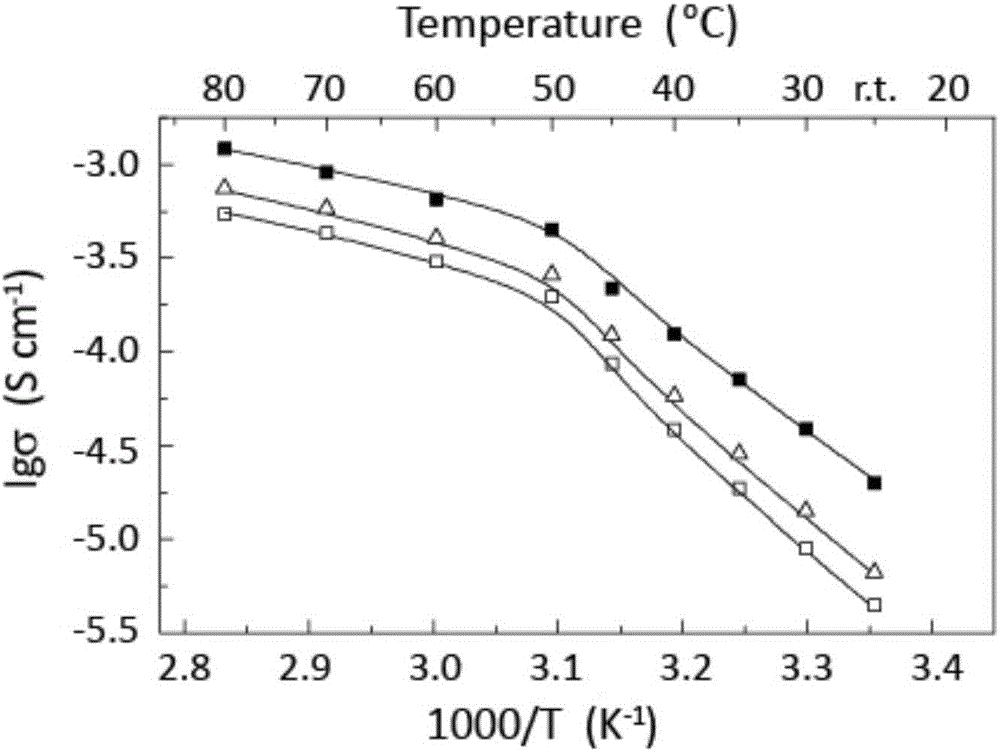

[0059] Using stainless steel as the blocking electrode, the electrochemical AC impedance test was carried out at different temperatures, and its conductivity was calculated. The results are as follows: figure 1 as sho...

Embodiment 2

[0063] Under the protection of argon atmosphere, after weighing PEO and LiTFSI according to the EO / Li molar ratio of 18:1, stir in acetonitrile to obtain solution A; 2 S, P 2 S 5 and LiI were weighed into acetonitrile according to the ratio of molar ratio (100-1)×(70:30):1, and stirred evenly at 50°C to obtain 99(70Li 2 S·30P 2 S 5 ) · 1LiI slurry B; according to 99 (70Li 2 S·30P 2 S 5 ) 1 LiI sulfide electrolyte accounted for 1% of the total mass of the composite electrolyte Mix solution A and slurry B, stir evenly to obtain solution C; cast solution C to be cast in a polytetrafluoroethylene mold, place in 50°C After 30 hours, the solvent was volatilized, and then placed in a muffle furnace for heat treatment at 250° C. for 0.5 h to completely volatilize the solvent to obtain a composite polymer electrolyte.

[0064] Using stainless steel as the blocking electrode, the electrochemical AC impedance test was carried out at different temperatures, and its conductivity was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com