Protective agent for improving vulcanization resistant properties of LED silver element, as well as preparation method and use method of protective agent

A protective agent and anti-vulcanization technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of not being able to protect the silver substrate of the LED well, the encapsulation resin is easy to breathe, and the environment causes pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

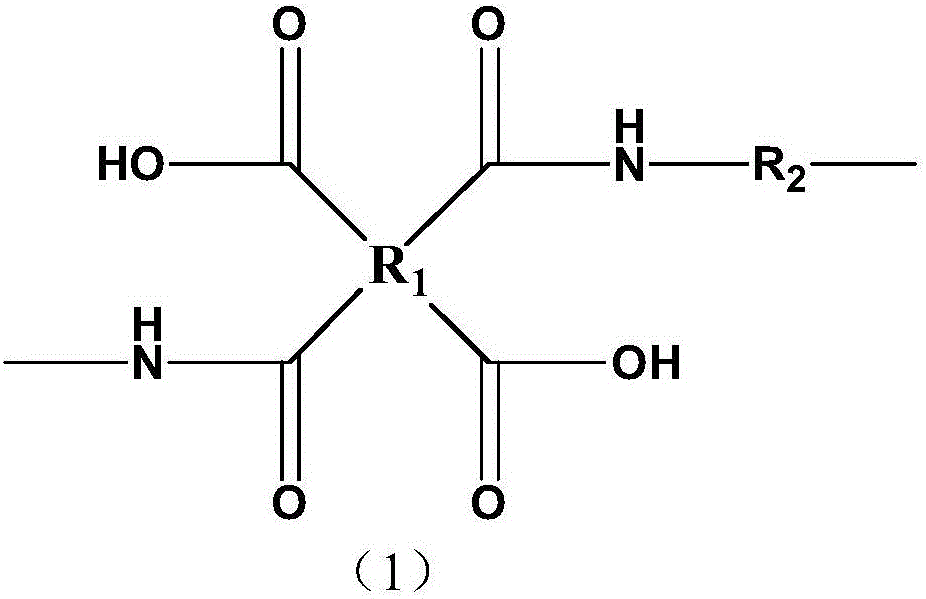

Method used

Image

Examples

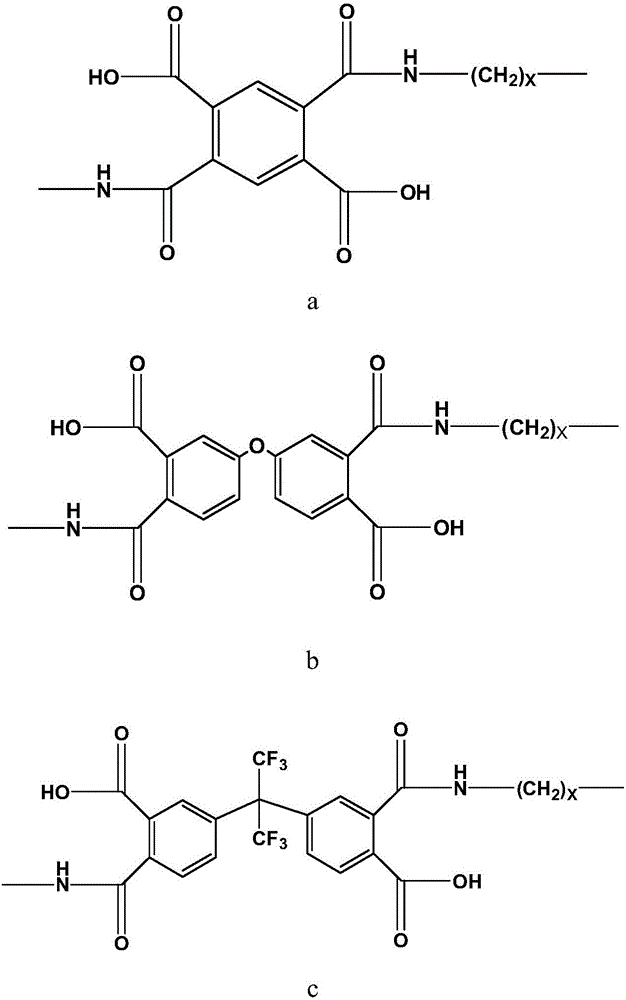

Embodiment 1

[0021] For the preparation of the anti-silver discoloration solution, use a three-necked flask as the reaction vessel, equipped with magnetic stirring, and pass it under the protection of nitrogen gas, accurately weigh 0.2 g of diamine 4,4'-diaminodiphenyl ether, and then add N,N-diaminodiphenyl ether Methyl acetamide 10ml, after the diamine is dissolved, weigh 0.3g of dianhydride 3,3',4,4'-benzophenonetetracarboxylic dianhydride and add it to a three-necked bottle, react at 25°C for 12h, and then It was stored at 4°C until use.

[0022] Take 1ml of the above solution, add 8.0ml N,N-dimethylacetamide, shake well, and name it A 1 , take A 1 1ml, add 9ml N,N-dimethylacetamide, shake well, named A 2 , take A 2 1ml, add 9ml N,N-dimethylacetamide, shake well, named A 3 . Take three LED silver components and immerse them in the above three solutions respectively. The solution should cover the LED silver substrate, and then take it out slowly. Do not allow the solution to overfl...

Embodiment 2

[0024] For the preparation of anti-silver discoloration solution, use a three-necked flask as a reaction vessel, equipped with magnetic stirring, and pass through nitrogen protection, accurately weigh diamine, 0.2g of 4,4'-diaminodiphenyl ether, and then add N,N- 10ml of dimethylformamide, after the diamine is dissolved, weigh the dianhydride, add 0.2g of pyromellitic dianhydride into a three-necked bottle, react at 25°C for 14h, and then store it at 4°C until use.

[0025] Take 1ml of the above solution, add 6ml of N,N-dimethylformamide, shake well, and name it B. Immerse the LED silver component into the above solution, the solution should cover the LED silver substrate, then take it out slowly, do not allow the solution to overflow the groove of the LED component, and then cure it in an oven at 60°C for 1 hour.

Embodiment 3

[0027] For the preparation of anti-silver discoloration solution, use a three-necked flask as a reaction vessel, equipped with magnetic stirring, and pass through nitrogen protection, accurately weigh diamine, 0.2g of 4,4'-diaminodiphenyl ether, and then add N,N- Dimethylacetamide 10ml, after the diamine is dissolved, weigh dianhydride, 4,4-oxodiphthalic anhydride 0.3g into a three-necked bottle, react at 25°C for 15h, then place it at 4°C Save it for later use.

[0028] Take 1ml of the above solution, add 8.0ml of N,N-dimethylacetamide, shake well, name it C, take the LED silver component and immerse it in the above solution, the solution can be submerged in the LED silver substrate, then take it out slowly, do not let the solution overflow the LED The grooves of the components were then cured in an oven at 40 °C for 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com