Method for measuring content of antimony in methyltin mercaptide composite heat stabilizer through indirect iodometric method

A technology of composite heat stabilizer and methyl tin antimony, which is applied in the direction of chemical analysis by titration method, can solve the problems of inability to detect antimony content, not suitable for determination of antimony content, difficult to judge the titration end point, etc., and is easy to popularize. and application, low cost, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 0.2003g of methyl tin antimony composite heat stabilizer sample, add 5ml98% sulfuric acid, 2ml68% nitric acid and 2ml70% perchloric acid successively, heat to dissolve, wait for it to cool to room temperature and add (1+9) hydrochloric acid solution to stabilize Make up to 100ml, shake well, set aside.

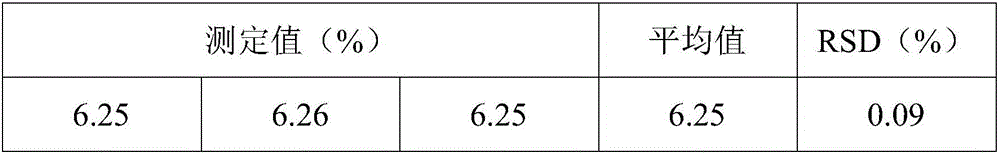

[0034] (2) Pipette 25ml of the solution prepared in step (1), add 0.5000g of potassium iodide and 1ml of 10g / l starch indicator, and use 0.0101M sodium thiosulfate standard titration solution to titrate until the blue color of the solution becomes colorless. At the end point, record the volume of sodium thiosulfate standard titration solution consumed as V 1 , At the same time, do a blank test and record the volume as 0.00ml. Calculate according to formula 1, and the results are shown in Table 1.

[0035] Table 1 Determination results of antimony content

[0036]

Embodiment 2

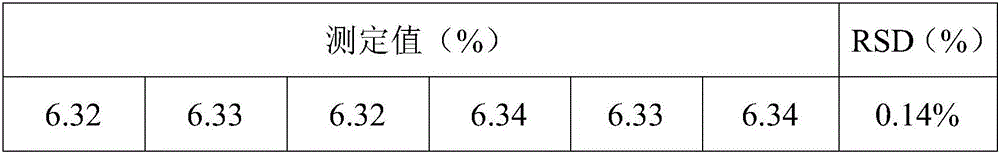

[0038] Take the same sample of methyl tin antimony composite heat stabilizer, take samples respectively by the same analysts, and repeat the measurement 6 times to investigate the precision. The results are shown in Table 2.

[0039] Table 2 Precision test results

[0040]

[0041] It can be seen from Table 1 and Table 2 that the method for detecting the antimony content of the methyl tin antimony composite heat stabilizer has good repeatability and high accuracy.

[0042] In summary, the present invention can be well used for the detection of the antimony content of the methyl tin-antimony composite heat stabilizer, the detection result is accurate and reliable, and does not require expensive special analytical instruments, the cost is low, and it is easy to popularize and apply. The application of methyl tin antimony compound heat stabilizer in PVC provides a scientific basis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com