Method of optimizing organic thin film transistor insulating layer by bi-crosslinking reaction

An organic thin film and insulating layer technology is applied in the field of optimizing the insulating layer of organic thin film transistors, which can solve the problems of easy aging, non-compactness, and influence on device performance, and achieve the effects of low cost, good optoelectronic performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

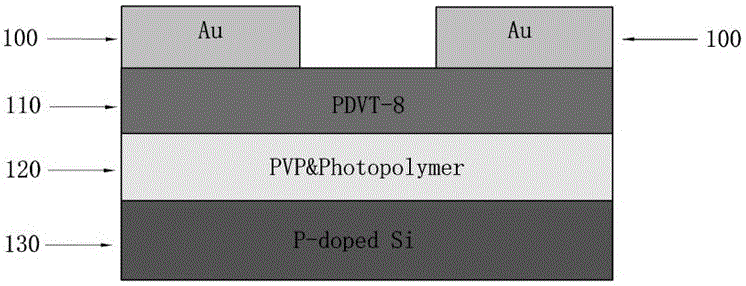

[0081] 1) Clean a P-type silicon wafer with a size of 1.5cm×2cm with acetone, isopropanol, chloroform, and distilled water (three times), and then dry it with nitrogen to obtain a clean silicon wafer as a gate.

[0082] 2) Use a syringe with a 0.22um filter plug to spread the 150mg / ml PVP solution over the silicon wafer, and then use a speed of 2000rpm (30s) to make the PVP solution form a uniform film on the silicon wafer, and then move the silicon wafer into the glove box for further processing. A 850nm insulating layer film was prepared by cross-linking reaction at 120°C (2h).

[0083] 3) The semiconductor polymer PDVT-8 was dissolved in chloroform at 5 mg / ml, and the PDVT-8 solution was spin-coated at 1000 rpm (60 s) to prepare the active layer, and then heated at 150 °C for 10 min.

[0084] 4) Finally, a 50nm-thick source-drain electrode with a channel length of 30um and a width of 1mm was evaporated on the silicon wafer obtained in step 5) by thermal evaporation using a ...

Embodiment 2

[0086] 1) Clean a P-type silicon wafer with a size of 1.5cm×2cm with acetone, isopropanol, chloroform, and distilled water (three times), and then dry it with nitrogen to obtain a clean silicon wafer as a gate.

[0087] 2) Use a syringe with a 0.22um filter plug to spread the 150mg / ml PVP solution over the silicon wafer, and then use a speed of 2000rpm (30s) to make the PVP solution form a uniform film on the silicon wafer, and then move the silicon wafer into the glove box for further processing. A 850nm insulating layer film was prepared by cross-linking reaction at 120°C (2h).

[0088] 3) Drop the methacrylic acid (MAA) small molecule monomer solution on the sample that has prepared the insulating layer film, among which, MAA liquid small molecule monomer: EGDMA: photoinitiator Irgacure 651=96:3:1, static After 2s, use 5000rpm (60) to remove excess small molecule monomer solution on the surface of the insulating layer.

[0089] 4) Prepare a 40w-BL Philips UV lamp, and place ...

Embodiment 3

[0094] 1) A P-type silicon wafer with a size of 1.5cm×2cm was blown dry with acetone, isopropanol, chloroform, distilled water (three times) and nitrogen to obtain a clean silicon wafer as a gate.

[0095] 2) Use a syringe with a 0.22um filter plug to spread the 150mg / ml PVP solution over the silicon wafer, and then use a speed of 2000rpm (30s) to make the PVP solution form a uniform film on the silicon wafer, and then move the silicon wafer into the glove box for further processing. A 850nm insulating layer film was prepared by cross-linking reaction at 120°C (2h).

[0096] 3) Drip the small molecule monomer solution of methyl methacrylate (MMA) on the sample that has prepared the insulating layer film, among which, MMA liquid small molecule monomer: EGDMA: photoinitiator Irgacure 651=96:3:1 After standing for 2s, use 5000rpm (60s) to remove excess small molecule monomer solution on the surface of the insulating layer.

[0097] 4) Prepare a 40w-BL Philips UV lamp, and place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com