Carbonaceous material for negative electrode of nonaqueous-electrolyte secondary battery, negative electrode for nonaqueous-electrolyte secondary battery, nonaqueous-electrolyte secondary battery, and vehicle

A non-aqueous electrolyte, secondary battery technology, applied in secondary batteries, battery electrodes, negative electrodes, etc., can solve problems such as the risk of metal lithium precipitation, and the insufficient input and output characteristics of secondary batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162] Hereinafter, although an Example demonstrates this invention concretely, these Examples do not limit the scope of this invention.

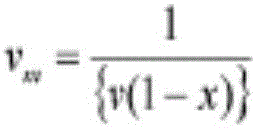

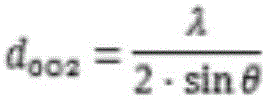

[0163] Hereinafter, although the physical property values (ρ Bt , ρ He , specific surface area (SSA), average particle size (D v50 ), hydrogen / carbon atomic ratio (H / C), d 002 , L c(002) , charge capacity, discharge capacity, irreversible capacity, moisture absorption, input and output value of 50% state of charge, DC resistance value, capacity retention rate, AC resistance value, high temperature storage loss capacity), but, including embodiments, this The physical property values described in the specification are based on the values obtained by the following methods.

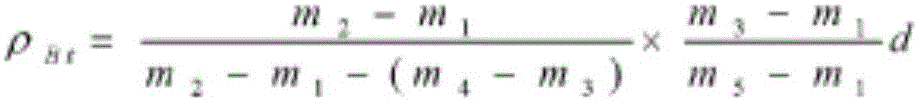

[0164] (true density obtained by the butanol method (ρ Bt ))

[0165] The true density was measured by the butanol method according to the method specified in JIS R7212. Accurately weigh the mass of a pycnometer with a side tube with an inner volume of about 40m...

manufacture example a-1

[0265] Put 70kg of petroleum pitch with a softening point of 205°C and an H / C atomic ratio of 0.65 and 30kg of naphthalene into a pressure-resistant container with a stirring blade and an outlet nozzle with an inner volume of 300 liters, heat, melt and mix at 190°C Thereafter, it was cooled to 80 to 90° C., and the inside of the pressure-resistant container was pressurized with nitrogen gas, and the contents were extruded through an outlet nozzle to obtain a rope-shaped molded body with a diameter of about 500 μm. Next, the rope-shaped molded body was pulverized so that the ratio (L / D) of the diameter (D) to the length (L) was about 1.5, and the obtained crushed product was put into a 0.53-mass melt heated to 93°C. % polyvinyl alcohol (saponification degree 88%) in the aqueous solution, stir and disperse, obtain spherical asphalt molded body slurry after cooling. After most of the water was removed by filtration, the naphthalene in the asphalt formed body was removed by extrac...

manufacture example a-2

[0269] Except that the oxidation temperature of the porous spherical pitch was changed to 240°C, and the particle size distribution was adjusted so that the pulverized particle size was changed to about 4 μm, a non-graphitizable carbon material a- 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com