MnO2-ACF material for removing indoor formaldehyde and preparation method thereof

A technology of formaldehyde and activated carbon fiber, which is applied in the field of MnO2-ACF materials and its preparation, can solve the problems of small adsorbent capacity, catalyst failure, and low conversion efficiency, and achieve simple preparation process, developed microporous structure, and large adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

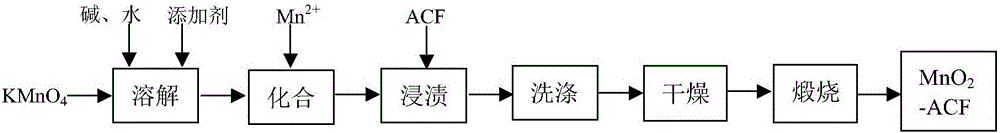

[0023] like figure 1 Shown, the MnO of the present invention 2 -ACF material is prepared by the following steps:

[0024] (1) 6.5 parts of KMnO 4 , 5.0 parts of NaOH, 1.2 parts of polyvinylpyrrolidone dissolved in 230 parts of pure water, stirred until KMnO 4 , NaOH and polyvinylpyrrolidone were completely dissolved to prepare mixed solution A; under stirring condition, the above mixed solution A was added dropwise by 7.8 parts MnSO 4 ·H 2 MnSO prepared by dissolving O in 260 parts of pure water 4 In the solution, after the dropwise addition, the reaction was continued for 1 hour to obtain a tan slurry B;

[0025] (2) Activated carbon fiber (ACF) is pretreated. The pretreatment process includes: immersing the ACF mat in 500ml ethanol, ultrasonic cleaning for 10min, taking out the ACF and cleaning it with 1000ml deionized water for 3 times, and then immersing the ACF in 500ml with a concentration of In 6% nitric acid solution, ultrasonically clean for 10 minutes, take out...

Embodiment 2

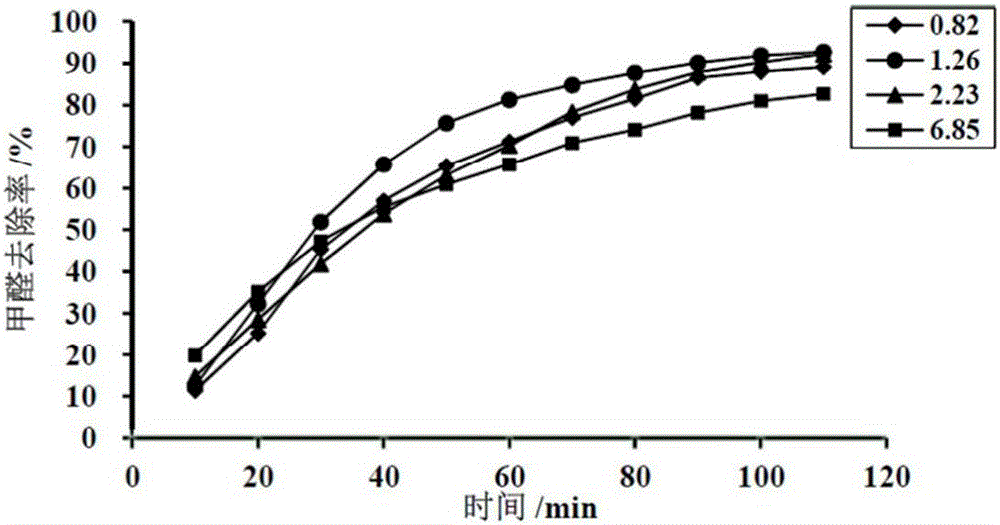

[0030] The basic steps are the same as in Example 1, except that the shaking time in step (3) is 30 minutes.

[0031] This example makes MnO 2 - MnO of ACF material 2 The loading rate is 10%, and the degradation rate of formaldehyde is 79.6% for indoor low-concentration formaldehyde treatment for 100 minutes.

Embodiment 3

[0033] MnO of the present invention 2 -ACF material is prepared by the following steps:

[0034] (1) 6.5 parts of KMnO 4 , 5.0 parts of NaOH, 1.2 parts of polyvinylpyrrolidone, 0.5 parts of hexadecylamine dissolved in 230 parts of pure water, stirred until KMnO 4 , NaOH, polyvinylpyrrolidone and hexadecylamine are completely dissolved to prepare a mixed solution A; under stirring conditions, the above mixed solution A is added dropwise by 7.8 parts of MnSO 4 ·H 2 MnSO prepared by dissolving O in 260 parts of pure water 4 In the solution, after the dropwise addition, the reaction was continued for 1 hour to obtain a tan slurry B;

[0035] (2) The activated carbon fiber (ACF) is pretreated first. The pretreatment process includes: soaking the ACF felt in 500ml ethanol, ultrasonic cleaning for 12min, taking out the ACF and washing it with 1000ml deionized water for 3 times, and then immersing the ACF in a concentration of 500ml In a 4% nitric acid solution, ultrasonically cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com