A Low-Surface Tension Solvent Directly Filled Airgel with Low Cost and Rapid Preparation

A low surface tension, gas-filled technology, applied in chemical instruments and methods, silicon dioxide, inorganic chemistry, etc., can solve the problems of high material cost and long preparation time, simplify the preparation process, reduce the amount of alcohol solvent, shorten the The effect of the preparation process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

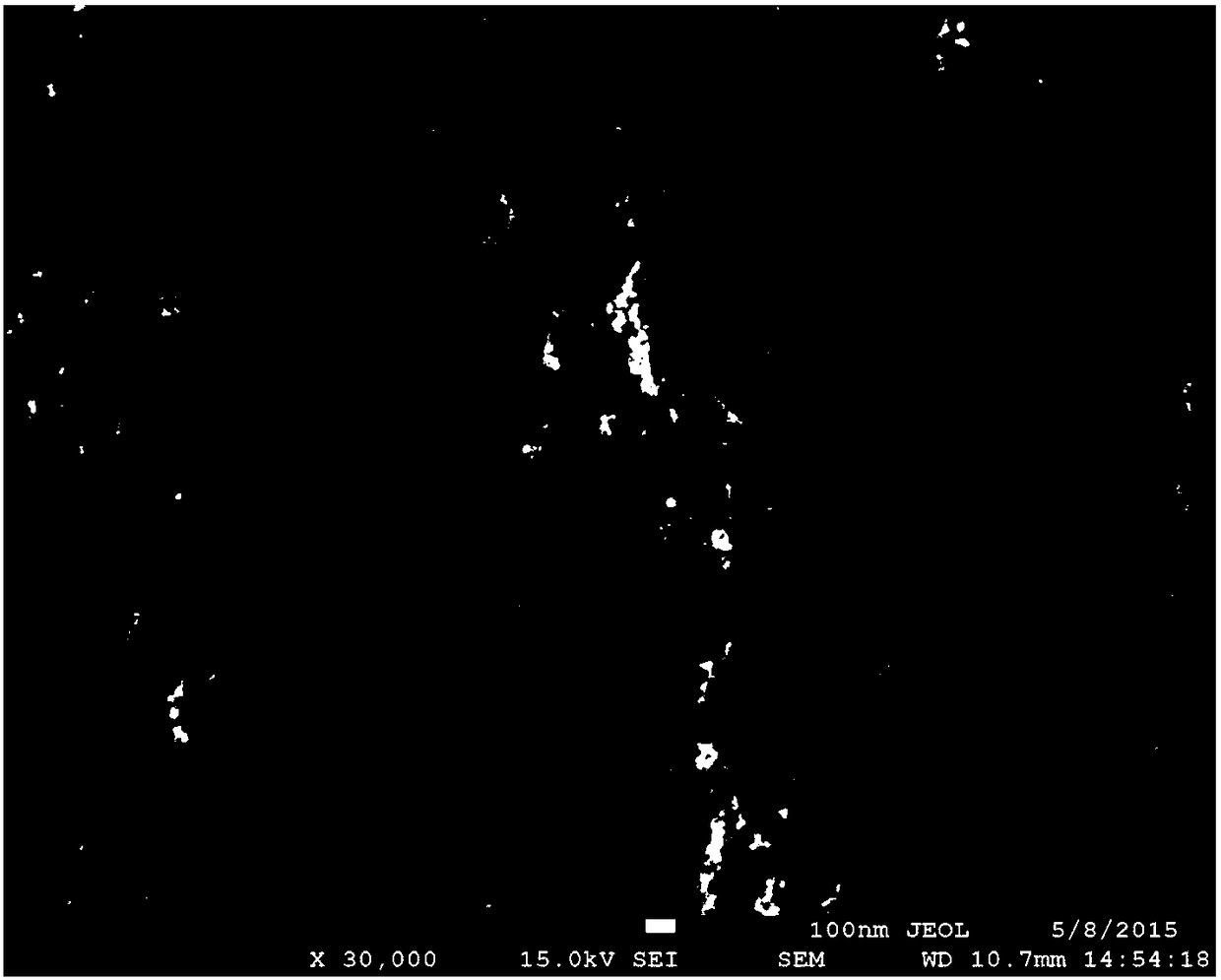

Image

Examples

Embodiment 1

[0035] According to the content of the present invention, the contriver makes airgel 1, concrete steps are as follows:

[0036] (1) Measure 50ml of tetraethyl orthosilicate at a temperature of 30°C, add 15ml of absolute ethanol to dilute, add 4ml of water, and adjust the pH value of the sol to 2 with a mass concentration of 1% hydrochloric acid, at a temperature of 40°C Leave for 2 hours.

[0037] (2) Then add 60ml of n-hexane, add 5ml of water, and then add ammonia water to adjust the pH value of the sol to 8, stir for 2 minutes to cast, and place at 30°C for 4 hours.

[0038] (3) The prepared wet gel was transferred to a mixture of trimethylchlorosilane and n-hexane with a volume ratio of 1:10, and soaked at 30°C for 8 hours.

[0039] (4) Next, the modified wet gel was transferred to n-hexane, and soaked at 30° C. for 20 minutes.

[0040] (5) Finally, place the cleaned gel in an oven at 70° C. for 8 hours at normal pressure, and in an oven at 200° C. for 2 hours to prepare...

Embodiment 2

[0043] According to the content of the present invention, the contriver makes airgel 2, concrete steps are as follows:

[0044] (1) Measure 50ml of tetraethyl orthosilicate at 30°C, add 15ml of absolute ethanol to dilute, add 4ml of water, and adjust the pH value of the sol to 2 with hydrochloric acid with a mass concentration of 1%. Set aside for 2 hours.

[0045] (2) Then add 50ml of n-hexane, add 3ml of water, and then add ammonia water to adjust the pH value of the sol to 8, stir for 2 minutes to cast the mold, and place it at 30°C for 4 hours.

[0046] (3) The prepared wet gel was transferred to a mixture of trimethylchlorosilane and n-hexane with a volume ratio of 1:10, and soaked at 30°C for 8 hours.

[0047] (4) Next, the modified wet gel was transferred to n-hexane, and soaked at 30° C. for 20 minutes.

[0048](5) Finally, place the cleaned gel in an oven at 70° C. for 8 hours and at 200° C. for 2 hours under normal pressure to prepare the aerogel.

[0049] SiO pre...

Embodiment 3

[0051] According to the content of the present invention, the contriver makes airgel 3, concrete steps are as follows:

[0052] (1) Measure 50ml of tetraethyl orthosilicate at 30°C, add 15ml of absolute ethanol to dilute, add 4ml of water, and adjust the pH value of the sol to 2 with hydrochloric acid with a mass concentration of 1%. Set aside for 2 hours.

[0053] (2) Then add 40ml of n-hexane, add 3ml of water, and then add ammonia water to adjust the pH value of the sol to 8, stir for 2 minutes to cast, and place at 30°C for 4 hours.

[0054] (3) The prepared wet gel was transferred to a mixture of trimethylchlorosilane and n-hexane with a volume ratio of 1:10, and soaked at 30°C for 8 hours.

[0055] (4) Next, the modified wet gel was transferred to n-hexane, and soaked at 30° C. for 20 minutes.

[0056] (5) Finally, place the cleaned gel in an oven at 70° C. for 10 hours and at 200° C. for 2 hours under normal pressure to prepare an airgel.

[0057] SiO prepared in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com