Photocatalytic biosorbent and its preparation method and application

A biosorbent, photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low adsorption and organic pollutant degradation efficiency , to achieve the effect of high photoelectron conversion rate, high photocatalytic efficiency and high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

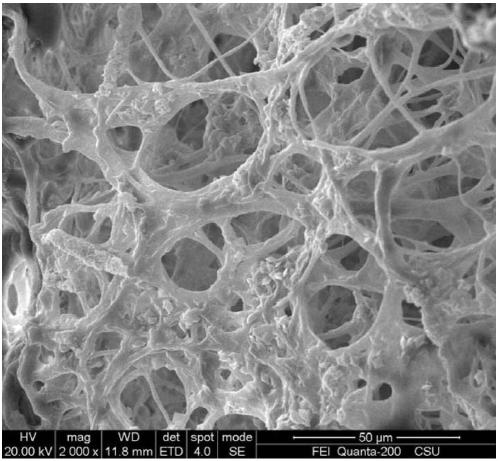

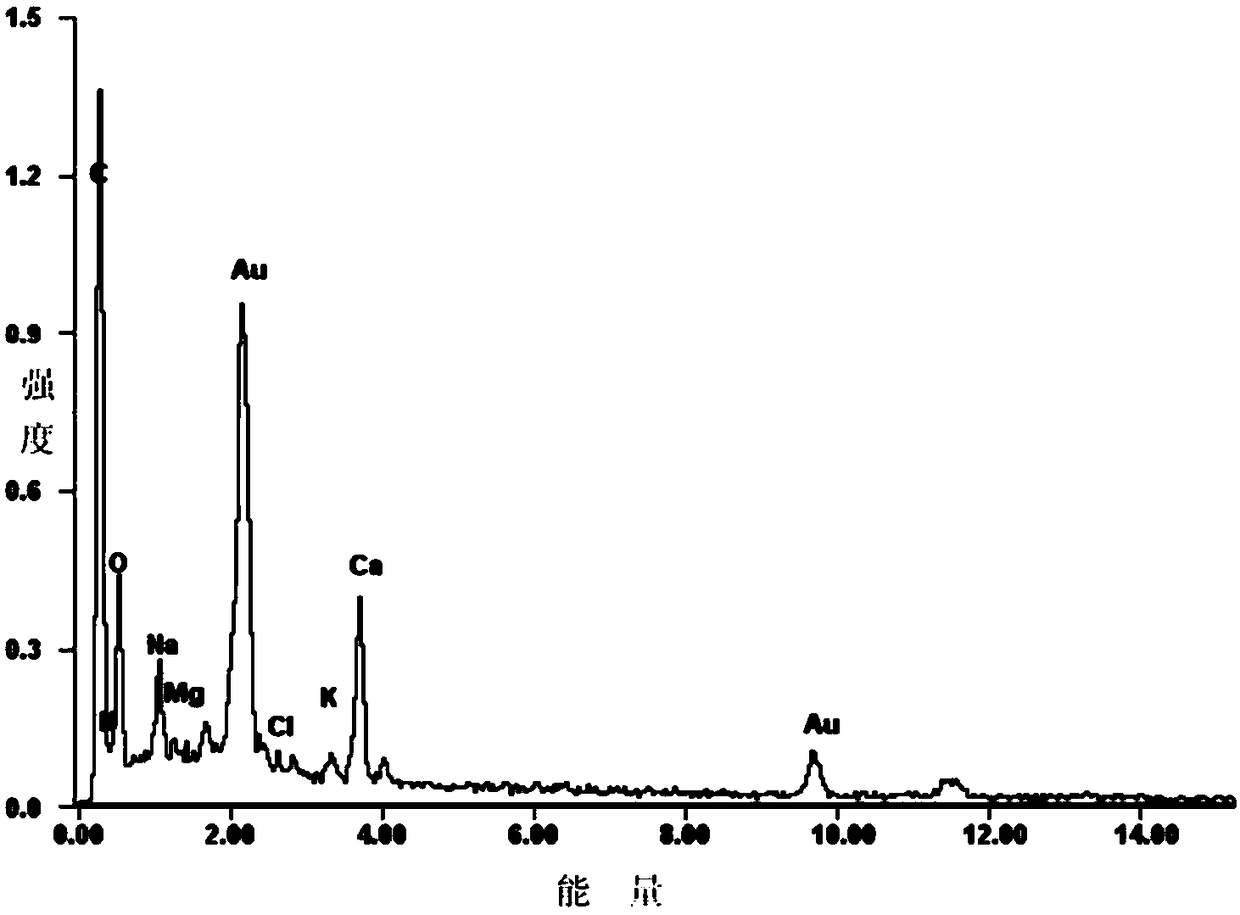

[0032] A kind of photocatalytic biosorbent of the present invention, this photocatalytic biosorbent comprises Phanerochaete chrysosporium bacterial ball, graphite type C 3 N 4 and calcium alginate; graphite type C 3 N 4 The hyphae of Phanerochaete chrysosporium balls are coated by calcium alginate.

[0033] A preparation method of the above-mentioned photocatalytic biosorbent of the present embodiment, comprising the following steps:

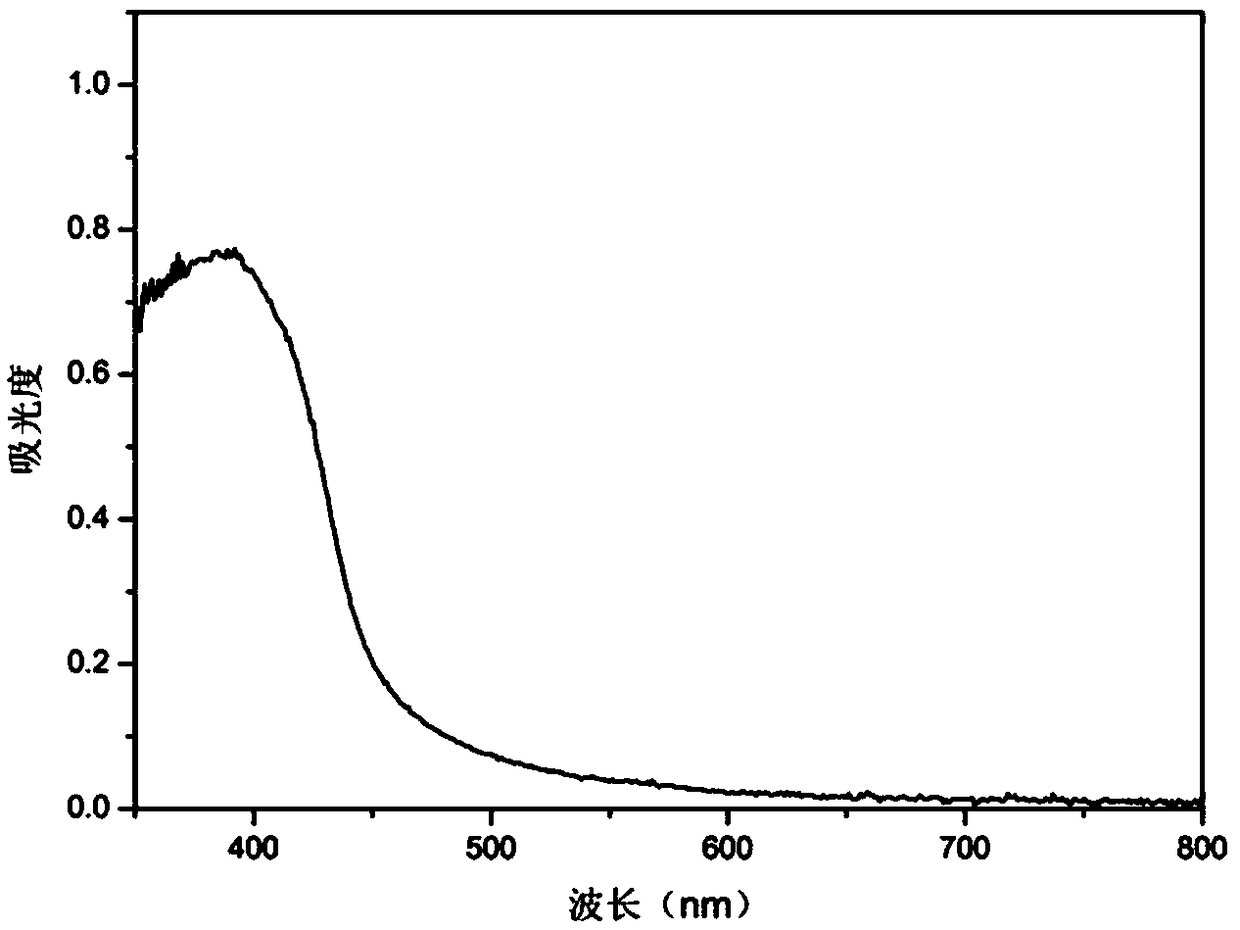

[0034] (1) Weigh 5g of urea into a 50mL crucible, cover the lid, and then wrap it tightly with tin foil; place the above sample in the middle of the muffle furnace for calcination. The calcination is specifically as follows: heating the urea from room temperature to 600° C. at a heating rate of 5° C. / min, and then keeping the temperature at 600° C. for calcination at a constant temperature for 2 hours. After cooling in the air, grind the sample in a mortar for 3 minutes, the resulting bright yellow powder is graphite type C 3 N 4 Material. ...

Embodiment 2

[0049] A kind of photocatalytic biosorbent of the present invention, this photocatalytic biosorbent comprises Phanerochaete chrysosporium bacterial ball, graphite type C 3 N 4 and calcium alginate; graphite type C 3 N 4 The hyphae of Phanerochaete chrysosporium balls are coated by calcium alginate.

[0050] A preparation method of the above-mentioned photocatalytic biosorbent of the present embodiment, comprising the following steps:

[0051] (1) Weigh 5g of urea into a 50mL crucible, cover the lid, and then wrap it tightly with tin foil; place the above sample in the middle of the muffle furnace for calcination. The calcination is specifically as follows: heating the urea from room temperature to 600° C. at a heating rate of 5° C. / min, and then keeping the temperature at 600° C. for calcination at a constant temperature for 2 hours. After cooling in the air, grind the sample in a mortar for 3 minutes, the resulting bright yellow powder is graphite type C 3 N 4 Material ...

Embodiment 3

[0057] A kind of application of the photocatalytic biosorbent of the present invention in the treatment of cadmium-containing and 2,4,6-trichlorophenol composite wastewater comprises the following steps:

[0058] To 100mL of cadmium and 2,4,6-trichlorophenol composite wastewater containing cadmium and 2,4,6-trichlorophenol with an initial concentration of 10mg / L and an initial concentration of 2,4,6-trichlorophenol, add 1g of the light compound prepared in Example 1. Catalyzed biosorbent S1 was placed in a shaking incubator, under the condition of 37°C and 150r / min for 72 hours of adsorption and degradation under light, and solid-liquid separation after standing to complete the adsorption and degradation of composite wastewater.

[0059] Figure 4 It is a picture of the removal effect of cadmium and 2,4,6-trichlorophenol by the photocatalytic biosorbent in this example under different treatment times. like Figure 4 Shown, for the compound waste water that initial concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com