Purification treatment method of industrial wastewater

A technology for industrial wastewater, purification and treatment, applied in multi-stage water treatment, aerobic process treatment, chemical instruments and methods, etc. Large-scale promotion and application, low operation and maintenance costs, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

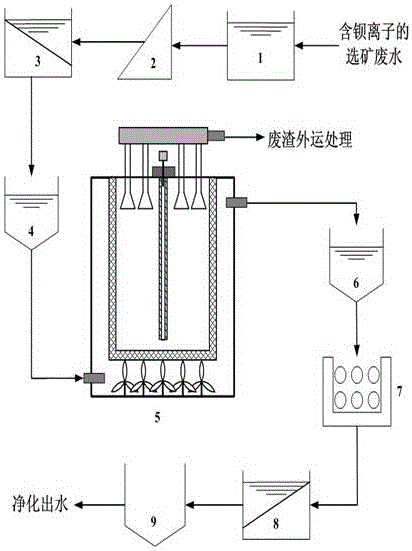

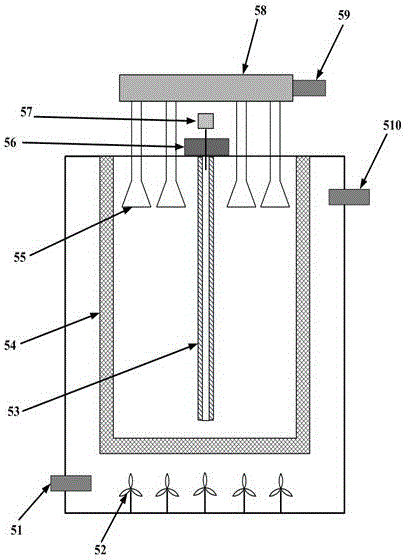

[0025] Such as figure 1As shown, the treatment method for removing COD in industrial wastewater, the industrial wastewater containing COD enters the collection well 1 through the wastewater pipeline, where it is collected and preliminarily stabilized. The outlet of the collection well 1 is connected to the coarse grid 2 through the wastewater pipeline. This removes large-diameter solid matter in the wastewater. The outlet of the coarse grid 2 is connected to the primary sedimentation tank 3 through the wastewater pipeline, where the insoluble substances in the wastewater are further removed. The outlet of the primary sedimentation tank 3 is connected to the pH adjustment tank 4 through the wastewater pipeline. , the pH value of the wastewater is precisely adjusted here. The pH value of the effluent from the pH value adjustment tank 4 ranges from 4.5 to 5.5 to meet the pH value requirements of the microbial oxidation battery-COD decomposition power generation device 5. The outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com