Environment-friendly low-resilience low-alkaline liquid setting accelerator and preparation method

A low-rebound, environmentally friendly technology, applied in the field of low-alkali liquid quick-setting agent for shotcrete and its preparation, can solve the problems of high price, high dosage, unfavorable promotion, etc., and achieves high adhesion and low rebound rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

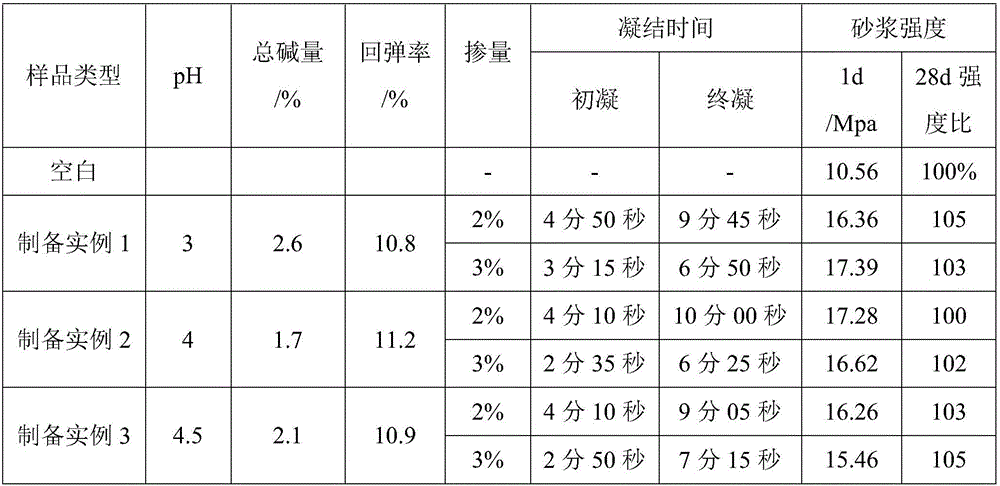

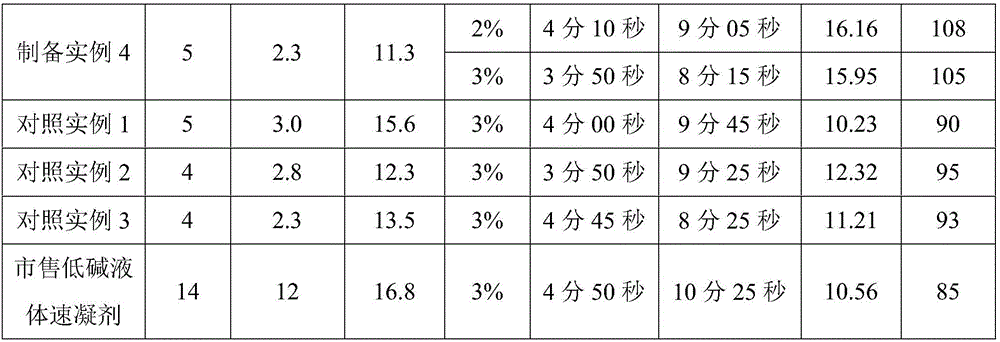

preparation Embodiment 1

[0029] (1) Preparation of modified polyaluminum sulfate solution

[0030] Dissolve 20g of polyaluminum sulfate (35% by mass of aluminum oxide) in 30g of water to form an aqueous solution of polyaluminum sulfate, add it dropwise to the bottom material of 18g of nano-alumina and 32g of aqueous solution, and perform ultrasonic reaction for 100 minutes , the reaction temperature is 75° C., and a stable transparent solution of modified polyaluminum sulfate is obtained.

[0031] (2) Preparation of modified fluoride salt

[0032] Dissolve 30g of sodium fluoride in 70g of nano-silica dispersion, and stir for 2 hours under high-shear conditions, and the high-speed shear should be at 2000S -1 , to obtain modified sodium fluoride.

[0033] (3) Preparation of modified alcohol amine

[0034] A mixture of 40 g of diethanolamine, 50 g of polyethylene polyamine and 10 g of ethyl orthosilicate was placed in a constant temperature water bath at 50° C. for 2 hours to obtain a modified alcohol...

preparation Embodiment 2

[0042] (1) Preparation of modified polyaluminum sulfate solution

[0043] Dissolve 35g of polyaluminum sulfate (33% by mass of aluminum oxide) in 45g of water to form an aqueous solution of polyaluminum sulfate, add it dropwise to the base material of 10g of nano-alumina and 10g of aqueous solution, and perform ultrasonic reaction for 60 minutes , the reaction temperature is 80° C., and a stable transparent solution of modified polyaluminum sulfate is obtained.

[0044] (2) Preparation of modified fluoride salt

[0045] Dissolve 20g of sodium fluoroaluminate in 80g of nano-silica dispersion, and stir for 3 hours under high-shear conditions, and the high-speed shear should be at 4000S -1 , to obtain modified sodium fluoroaluminate.

[0046] (3) Preparation of modified alcohol amine

[0047]A mixture of 60 g of triethanolamine, 37 g of polyethylene polyamine and 3 g of N,N-methylenebisacrylamide was placed in a constant temperature water bath at 40° C. for 3 hours to obtain a...

preparation Embodiment 3

[0055] (1) Preparation of modified polyaluminum sulfate solution

[0056] Dissolve 25g of polyaluminum sulfate (30% by mass of aluminum oxide) in 40g of water to form an aqueous solution of polyaluminum sulfate, add it dropwise to the base material of 15g of nano-alumina and 20g of aqueous solution, and perform ultrasonic reaction for 120 minutes , the reaction temperature is 85° C., and a stable transparent solution of modified polyaluminum sulfate is obtained.

[0057] (2) Preparation of modified fluoride salt

[0058] Dissolve 10g of sodium fluorosilicate in 90g of nano-silica dispersion, stir for 3 hours under high-shear conditions, and the high-speed shear should be at 6000S -1 , to obtain modified sodium fluorosilicate.

[0059] (3) Preparation of modified alcohol amine

[0060] A mixture of 45 g of diethanol monoisopropanolamine, 50 g of polyethylene polyamine and 5 g of diethylenetriamine was placed in a constant temperature water bath at 20° C. for 3.5 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com