Method for synthesizing benzoquinone compound through catalytic oxidation of phenol compound

A phenolic compound, catalytic oxidation technology, applied in the preparation of quinone oxide, organic chemistry, etc., to achieve the effects of environmental friendliness, mild reaction conditions and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

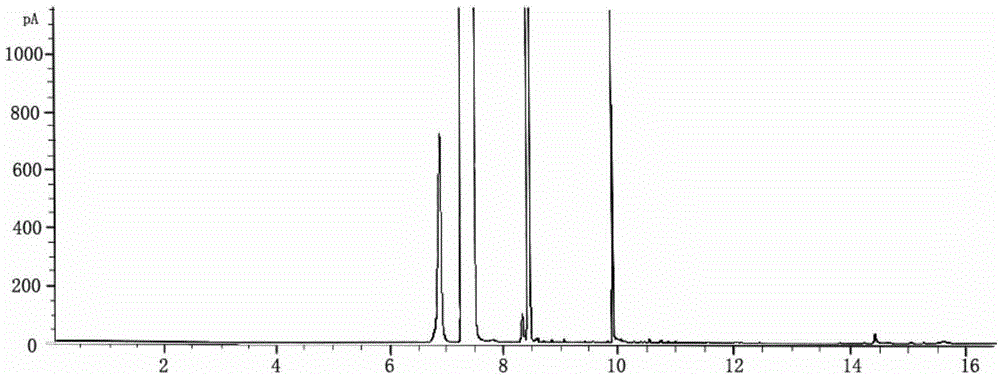

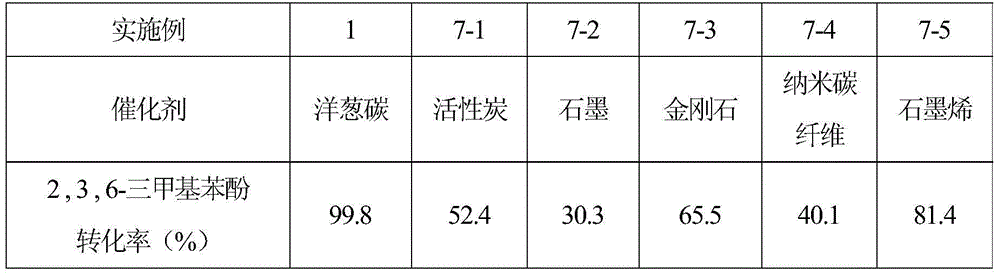

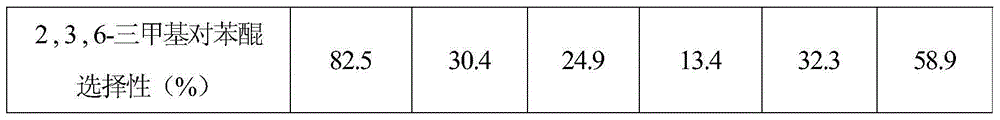

[0025] Add 0.1 mmol of 2,3,6-trimethylphenol, benzotrifluoride, solid catalyst onion carbon, and oxidant tert-butyl hydroperoxide into a closed glass container for mixing, and then ultrasonicate to form a suspension (5 min). Among them, benzotrifluoride is 5ml, and the molar ratio of onion carbon to 2,3,6-trimethyl-p-phenol is 6.66:1. The molar ratio of oxidizing agent to 2,3,6-trimethyl-p-phenol is 3.6:1. The mixed suspension was placed in an oil bath and heated to 80 °C under stirring. After reacting for 12 hours, take out reaction vessel from oil bath, cool to room temperature, pour out liquid-solid mixture, it is filtered, obtain solid catalyst and remaining liquid phase mixture, add a certain amount of internal standard (ethylbenzene), to This liquid phase mixture is analyzed, and the retention time ( figure 1 ) are: tert-butanol 6.9min, trifluorotoluene 7.4min, 2,3,6-trimethyl-p-benzoquinone 9.91min, 2,3,6-trimethylphenol 9.98min, ethylbenzene 8.4min. The selectivity ...

Embodiment 2

[0027] Add 0.1 mmol of 2,3,6-trimethylphenol, benzotrifluoride, solid catalyst onion carbon, and oxidant tert-butyl hydroperoxide into a closed glass container for mixing, and then ultrasonicate to form a suspension (5 min). Among them, benzotrifluoride is 5ml, and the molar ratio of onion carbon to 2,3,6-trimethylphenol is 6.66:1. The molar ratio of oxidizing agent to 2,3,6-trimethylphenol is 3.6:1. The mixed suspension was placed in an oil bath and heated to the temperature shown in Table 1 under stirring conditions. After reacting for 12 hours, take out reaction vessel from oil bath, cool to room temperature, pour out liquid-solid mixture, it is filtered, obtain solid catalyst and remaining liquid phase mixture, add a certain amount of internal standard (ethylbenzene), to The liquid phase mixture is analyzed, and the conversion rate of 2,3,6-trimethylphenol and the selectivity results of 2,3,6-trimethyl-p-benzoquinone are shown in Table 1. It can be seen that the temperatu...

Embodiment 3

[0032]Add 0.1 mmol of 2,3,6-trimethylphenol, trifluorotoluene, solid catalyst onion carbon, and oxidant tert-butyl hydroperoxide into a closed glass container and mix them, and form a suspension under ultrasonic treatment (5 minutes). Among them, benzotrifluoride is 5ml, and the molar ratio of onion carbon to 2,3,6-trimethylphenol is 6.66:1. The molar ratio of oxidizing agent to 2,3,6-trimethylphenol is 3.6:1. The mixed suspension was placed in an oil bath and heated to 80 °C under stirring. Reaction time to Table 2, take out reaction vessel from oil bath, cool to room temperature, pour out liquid-solid mixture, it is filtered, obtain solid catalyst and remaining liquid phase mixture, add a certain amount of internal standard (ethylbenzene), The liquid phase mixture is analyzed, and the conversion rate of 2,3,6-trimethylphenol and the selectivity of 2,3,6-trimethyl-p-benzoquinone are measured. The results are shown in Table 2. It can be seen that prolonging the time is benefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com