Device and process for preparing dimethyl carbonate

A technology of dimethyl carbonate and propylene carbonate, applied in the purification/separation of carbonate/haloformate, preparation of carbonate/haloformate, preparation of organic carbonate, etc. Problems such as industrial production, to achieve the effect of reducing equipment investment and production energy consumption, reducing process requirements, and good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

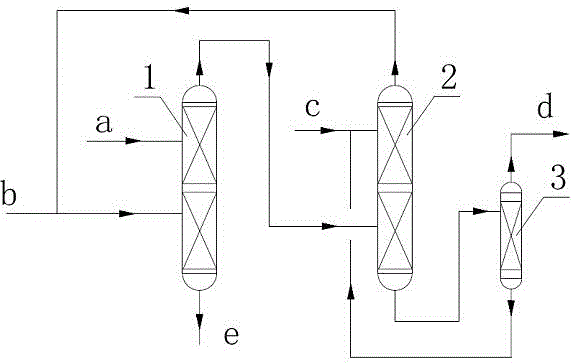

[0047] A device for preparing dimethyl carbonate by using a new type of structured packing, comprising a reactive distillation tower 1, an extractive distillation tower 2 and an extraction agent recovery tower 3.

[0048] The side of the reactive distillation tower is equipped with a reactive distillation tower methanol inlet and a reactive distillation tower propylene carbonate inlet, the top of the tower is equipped with a reactive distillation tower top outlet, and the bottom of the tower is equipped with a reactive distillation tower Outlet at the bottom of the tower.

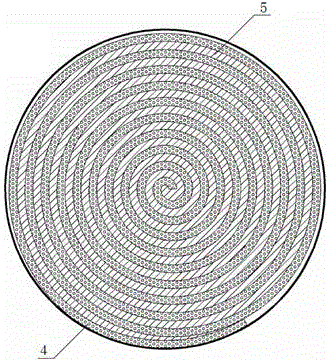

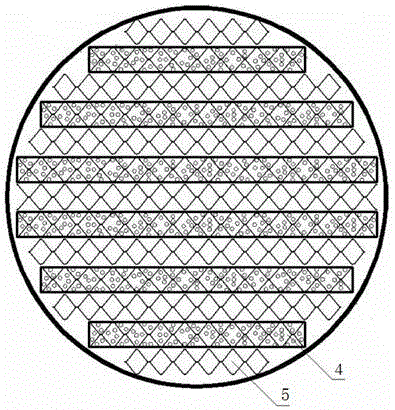

[0049] The rectification section and the reaction section of the reactive distillation tower adopt window-opening flow-guiding structured packing, and the packing sheets of the window-opening flow-guiding structured packing are corrugated packing sheets, see Figure 5As shown, it includes crests 6, troughs 7, and flow guide windows 8 formed on the crests and troughs by cutting. Each packing layer contains ...

Embodiment 2

[0070] The device that utilizes novel structured packing to prepare dimethyl carbonate that adopts in the present embodiment is identical with that in embodiment 1.

[0071] In the present embodiment, adopt above-mentioned device to carry out reactive distillation and produce the processing step of dimethyl carbonate as:

[0072] 1.1. Add propylene carbonate to the reactive distillation column through the propylene carbonate feed port of the reactive distillation column, and add fresh methanol and separated and recovered methanol into the reactive distillation column through the methanol feed port of the reactive distillation column , propylene carbonate and methanol react under the action of a catalyst to generate dimethyl carbonate and propylene glycol. After rectification, the light components containing methanol and dimethyl carbonate azeotrope are extracted from the top outlet of the reactive distillation tower, and the heavy components containing propylene glycol and par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com