Polyimide composite film and preparing method thereof

A technology of polyimide and composite film, which is applied in the field of polyimide composite film and its preparation, can solve the problems of increasing production costs, etc., and achieve the effects of low cost, improved mechanical properties, good stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of polyimide composite film, obtains by following method:

[0053] (1) Modification of Halloysite:

[0054] ①Short-chain modifier modification: heat halloysite at 200°C for 10h, take 2.0g and disperse it into 100.0mL of ethanol and 15.0mL of ammonia water, stir at room temperature for 2h, raise the temperature to 60°C, add 1.0 mL of tetraethyl orthosilicate, continue to stir for 6h; filter the obtained slurry, wash with ethanol several times, and dry at 110°C for 12h to obtain short-chain modified halloysite;

[0055] ②Preparation of long-chain coupling agent hydrolyzate: add 1.0mL of γ-aminopropyltriethoxysilane to a mixture of 0.5mL of water and 10.0mL of ethanol for 1 hour, adjust the pH to 4 with anhydrous acetic acid, Stir for 1h to obtain a long-chain coupling agent hydrolyzate;

[0056] ③Long-chain coupling agent modification: take 2.0g of the short-chain modified halloysite obtained in step ① and disperse it in 100.0mL of ethanol, stir for 2h, and then ...

Embodiment 2

[0065] A kind of polyimide composite film, obtains by following method:

[0066] (1) Modification of Halloysite:

[0067] ①Short-chain modifier modification: Heat halloysite at 600°C for 5h, take 5.0g and disperse it into 160.0mL of ethanol and 18.0mL of ammonia water, stir at room temperature for 2h; raise the temperature to 60°C, add 3.0ml Tetraethyl orthosilicate, continue to stir for 6h; filter the obtained slurry, wash with ethanol several times, and dry at 110°C for 12h to obtain short-chain modified halloysite;

[0068] ②Preparation of long-chain coupling agent hydrolyzate: add 2.0mL of γ-aminopropylmethyldiethoxysilane to a mixture of 1.0mL water and 12.0mL ethanol for 1h, adjust the pH to 5. Stir for 1 hour to obtain a long-chain coupling agent hydrolyzate;

[0069] ③Long-chain coupling agent modification: Take 3.0g of the short-chain modified halloysite obtained in step ① and disperse it in 100.0mL of ethanol, stir for 2h, and then dissolve the hydrated γ-aminoprop...

Embodiment 3

[0076] A kind of polyimide composite film, obtains by following method:

[0077] (1) Modification of Halloysite:

[0078] ①Short chain modifier modification: heat halloysite at 1000°C for 1h, take 10.0g and disperse it into 200.0mL of ethanol and 20.0mL of ammonia water, stir at room temperature for 2h; raise the temperature to 60°C, add 10.0mL Tetraethyl orthosilicate, continue to stir for 6h; filter the obtained slurry, wash with ethanol several times, and dry at 110°C for 12h to obtain short-chain modified halloysite;

[0079] ②Preparation of long-chain coupling agent hydrolyzate: Add 3.5mL of γ-aminopropylmethyldiethoxysilane to a mixture of 2.0mL water and 15.0mL ethanol for 1h, and adjust the pH to 6. Stir for 1 hour to obtain a long-chain coupling agent hydrolyzate;

[0080] ③Long-chain coupling agent modification: Take 10.0g of the short-chain modified halloysite obtained in step ① and disperse it in 100.0mL of ethanol, stir for 2h, and then dissolve the hydrated γ-a...

PUM

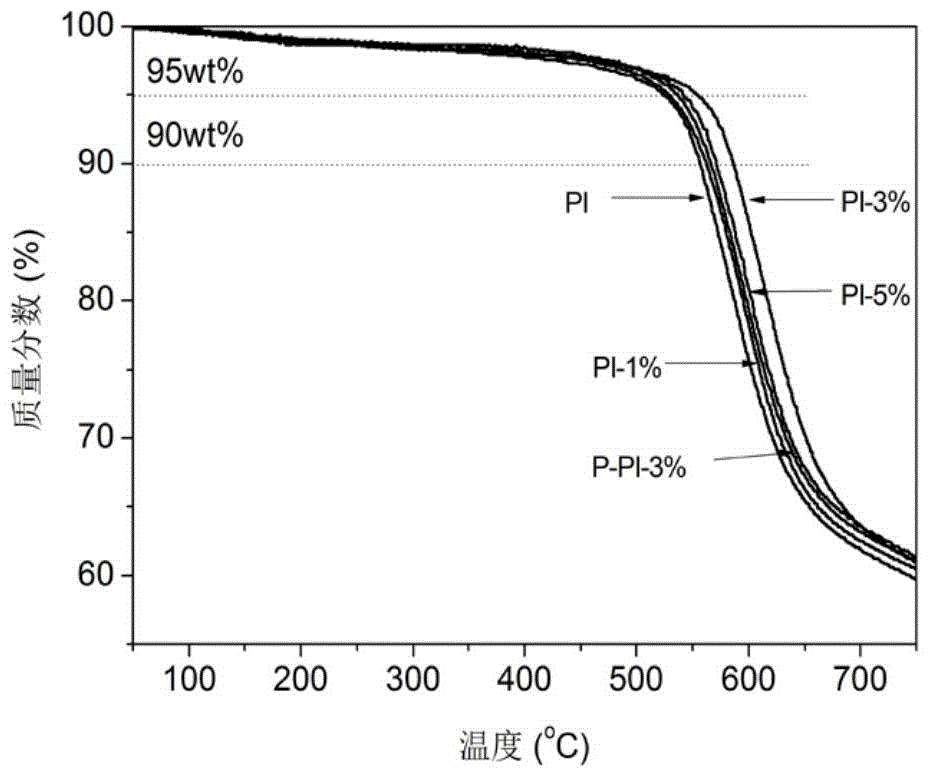

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com