Armor plate for C-level securicar and preparation method thereof

A technology of bulletproof steel plate and banknote transport vehicle, which is applied in the field of steel plate production, can solve the problems of unfavorable steel plate surface quality control, toughness index not mentioned, and high carbon content of bulletproof steel, so as to increase welding difficulty, improve billet quality, high The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

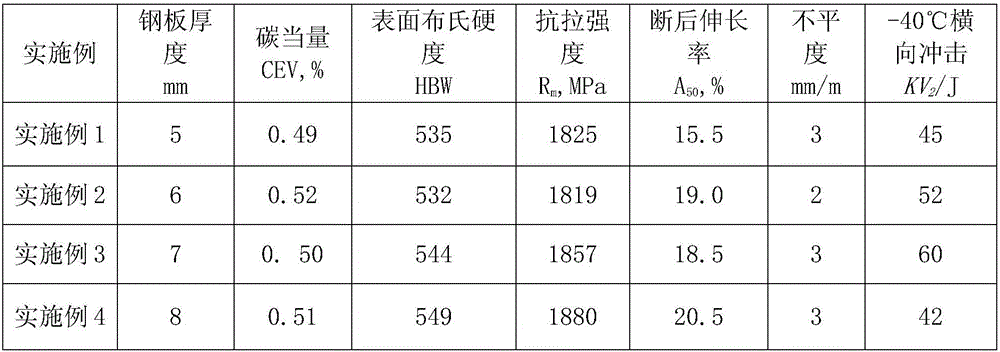

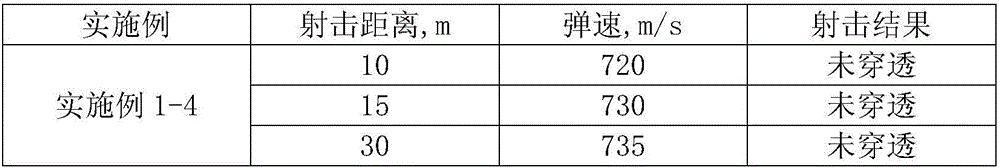

Examples

Embodiment 1

[0022] Bulletproof steel plate for Class C cash transport vehicle with a thickness of 5mm.

[0023] The smelting chemical composition of the steel plate is: C: 0.22%; Si: 0.12%; Mn: 1.05%; P: 0.006%; S: 0.002%; Alt: 0.025%; Cr: 0.33%; Mo: 0.11%; Ti: 0.018%; [O]: 5ppm; [N]: 8ppm; [H]: 1ppm; the rest is Fe and unavoidable impurities.

[0024] The specific key steps and key parameters for preparing the above-mentioned steel plates are as follows:

[0025](1) Rough rolling in 4-roller roughing mill, number of rolling passes: 4, intermediate billet thickness: 30mm, average reduction speed 32mm / s;

[0026] (2) 4-high finishing mill finishing rolling, rolling time: 2.4min, number of rolling passes: 4, average reduction speed: 42mm / s;

[0027] (3) Vacuum quenching, vacuum degree: 0.5×10 5 Pa, heating temperature: 875°C, heating time: 22min, water cooling cooling rate: 44°C / s;

[0028] (4) Stress relief annealing, annealing temperature: 300°C, holding time: 15min, cooling rate: 1.2...

Embodiment 2

[0031] Bulletproof steel plate for Class C cash transport vehicle with a thickness of 6mm.

[0032] The smelting chemical composition of the steel plate is: C: 0.23%; Si: 0.16%; Mn: 1.20%; P: 0.007%; S: 0.003%; Alt: 0.028%; Cr: 0.26%; Mo: 0.15%; Ti: 0.022%; [O]: 6ppm; [N]: 10ppm; [H]: 2ppm; the rest is Fe and unavoidable impurities.

[0033] The specific key steps and key parameters for preparing the above-mentioned steel plates are as follows:

[0034] (1) Rough rolling in 4-roller roughing mill, number of rolling passes: 5, intermediate billet thickness: 30mm, average reduction speed 35mm / s;

[0035] (2) 4-high finishing mill finishing rolling, rolling time: 2.0min, number of rolling passes: 3, average reduction speed: 45mm / s;

[0036] (3) Vacuum quenching, vacuum degree: 0.7×10 5 Pa, heating temperature: 885°C, heating time: 20min, water cooling cooling rate: 41°C / s;

[0037] (4) Stress relief annealing, annealing temperature: 315°C, holding time: 13min, cooling rate: 1...

Embodiment 3

[0040] Bulletproof steel plate for Class C cash transport vehicle with a thickness of 7mm.

[0041] The smelting chemical composition of the steel plate is: C: 0.22%; Si: 0.20%; Mn: 1.15%; P: 0.005%; S: 0.001%; Alt: 0.022%; Cr: 0.29%; Mo: 0.11%; Ti: 0.020%; [O]: 5ppm; [N]: 5ppm; [H]: 1ppm; the rest is Fe and unavoidable impurities.

[0042] The specific key steps and key parameters for preparing the above-mentioned steel plates are as follows:

[0043] (1) Rough rolling in 4-roller roughing mill, number of rolling passes: 5, intermediate billet thickness: 30mm, average reduction speed 32mm / s;

[0044] (2) 4-high finishing mill for finishing rolling, rolling time: 2.5min, number of rolling passes: 4, average reduction speed: 41mm / s;

[0045] (3) Vacuum quenching, vacuum degree: 0.6×10 5 Pa, heating temperature: 890°C, heating time: 17min, water cooling cooling rate: 43°C / s;

[0046] (4) Stress relief annealing, annealing temperature: 295°C, holding time: 15min, cooling ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com