Group III nitride enhanced hemt device and manufacturing method thereof

A manufacturing method and nitride technology, which are applied in the field of microelectronics, can solve the problems affecting the mobility of two-dimensional electron gas, small source-leakage current, and etching barrier layers, so as to achieve mature process steps, less mobility reduction, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

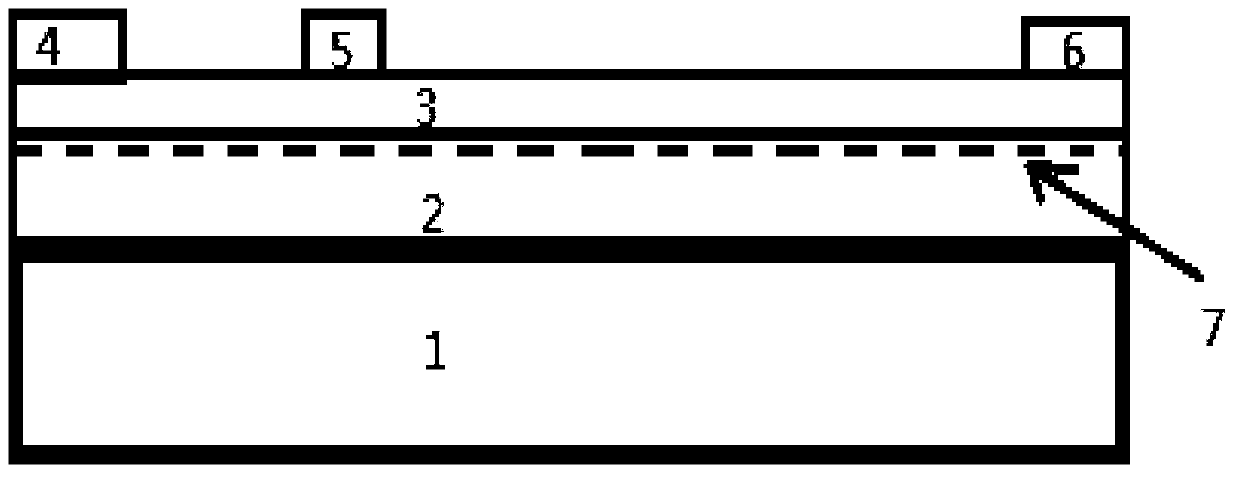

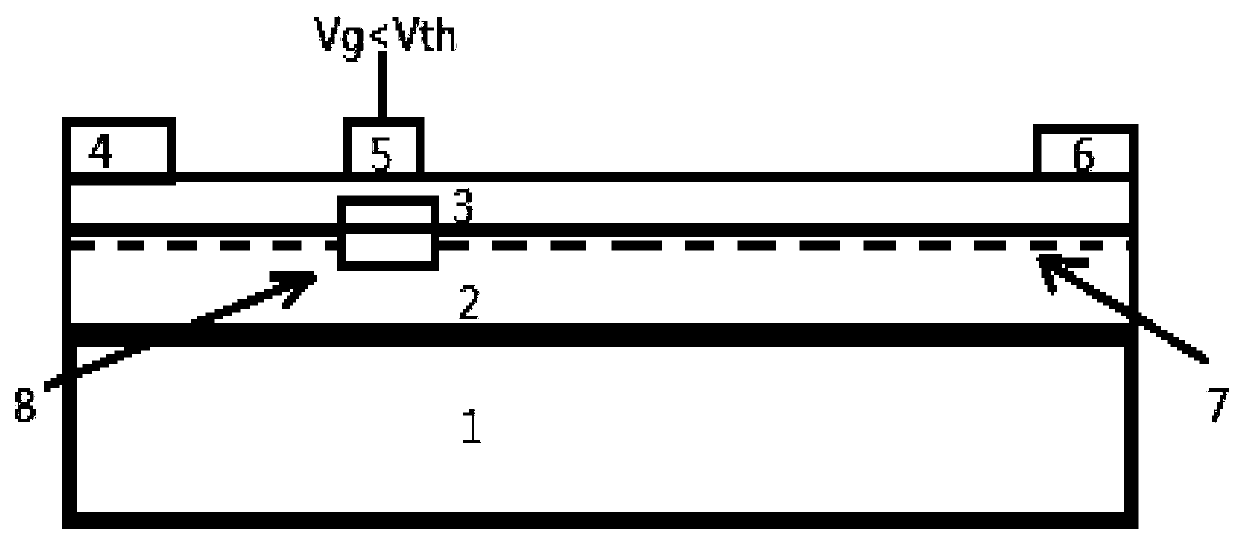

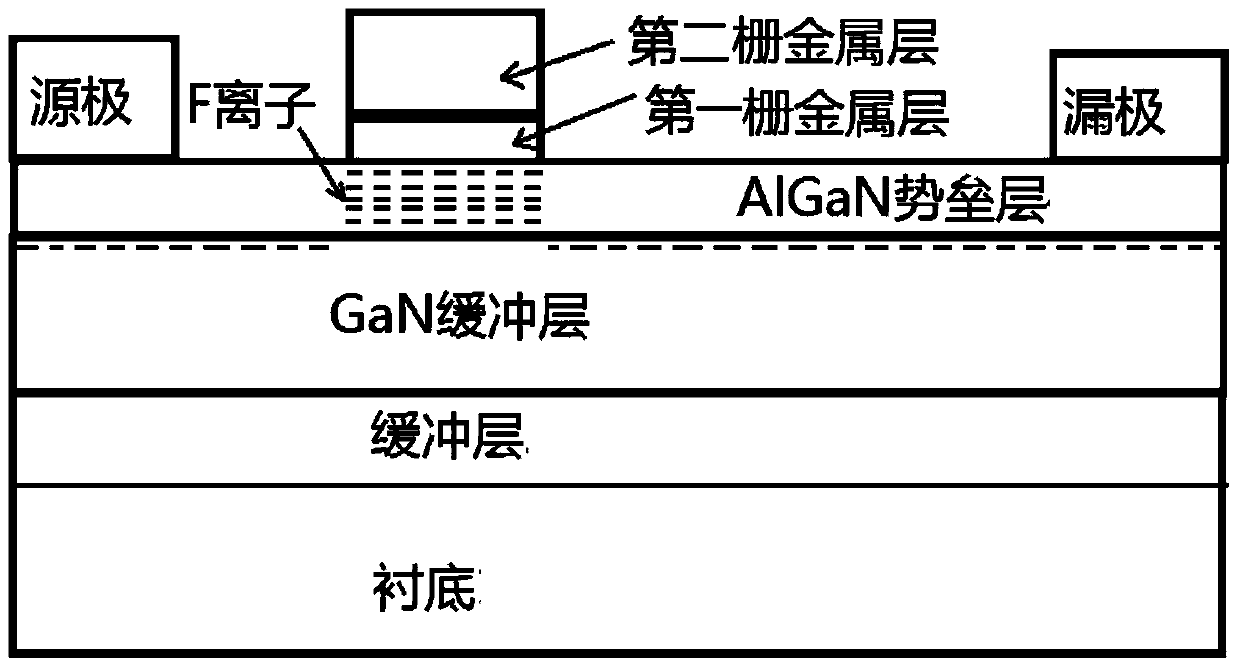

[0072] Embodiment 1 please refer again image 3 with Figure 4 , the HEMT has: a first semiconductor 2 (GaN), and a second semiconductor 3 (AlGaN) formed on the first semiconductor 2 . The first semiconductor 2 is not intentionally doped. The second semiconductor 3 may be doped with n-type impurities, or may not be doped. The band gap of the second semiconductor 3 is wider than that of the first semiconductor 2 . The thickness of the second semiconductor 3 is about 15 to 30 nm. The first semiconductor 2 and the second semiconductor 3 form a heterostructure, forming a two-dimensional electron gas (2DEG) at the interface.

[0073] This HEMT has a drain electrode 6 and a source electrode 4 arranged at a distance apart. The drain electrode 6 and the source electrode 4 extend through the second semiconductor 3 to the first semiconductor 2 and are connected to the two-dimensional electron gas in the channel. The drain electrode 6 and the source electrode 4 are made of multilay...

Embodiment 2

[0077] Embodiment 2 This MIS-HEMT has: a first semiconductor 2 (GaN), and a second semiconductor 3 (AlGaN) formed on the first semiconductor 2 . The first semiconductor 2 is not intentionally doped. The second semiconductor 3 may be doped with n-type impurities, or may not be doped. The band gap of the second semiconductor 3 is wider than that of the first semiconductor 2 . The thickness of the second semiconductor 3 is about 15 to 30 nm. The first semiconductor 2 and the second semiconductor 3 form a heterostructure, forming a two-dimensional electron gas (2DEG) at the interface.

[0078]This MIS-HEMT has a drain electrode 6 and a source electrode 4 arranged at predetermined intervals. The drain electrode 6 and the source electrode 4 extend through the second semiconductor 3 to the first semiconductor 2, and are connected to the two-dimensional electron gas in the channel. The drain electrode 6 and the source electrode 4 are made of multilayer metals (such as: Ti / Al / Ti / Au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com