Degradable self-locking cervical vertebra fusion cage and preparation method thereof

A cage, self-locking technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problem of swallowing foreign body sensation in the throat of patients, non-fusion between vertebral bodies, and subsidence of the cage, avoiding complications, strong initial The effect of mechanical stability and cost-saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 nanoscale β-tricalcium phosphate

[0048] 1) Prepare micron-sized β-TCP particles that meet the β-TCP standard for surgical implants as raw materials;

[0049] 2) Disperse micron-sized β-TCP particles in a diethylene glycol dispersion, use zirconia beads as the ball milling medium, and continuously ball mill at a speed of 1800r / min for 12 hours;

[0050] 3) Centrifuge to remove diethylene glycol dispersion;

[0051] 4) Rinse with dichloromethane, dry in vacuum, and store.

Embodiment 2

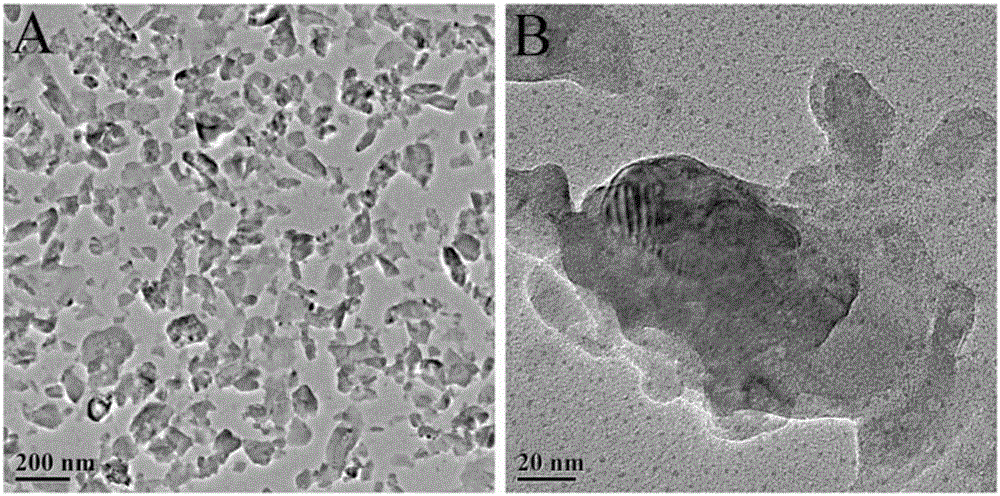

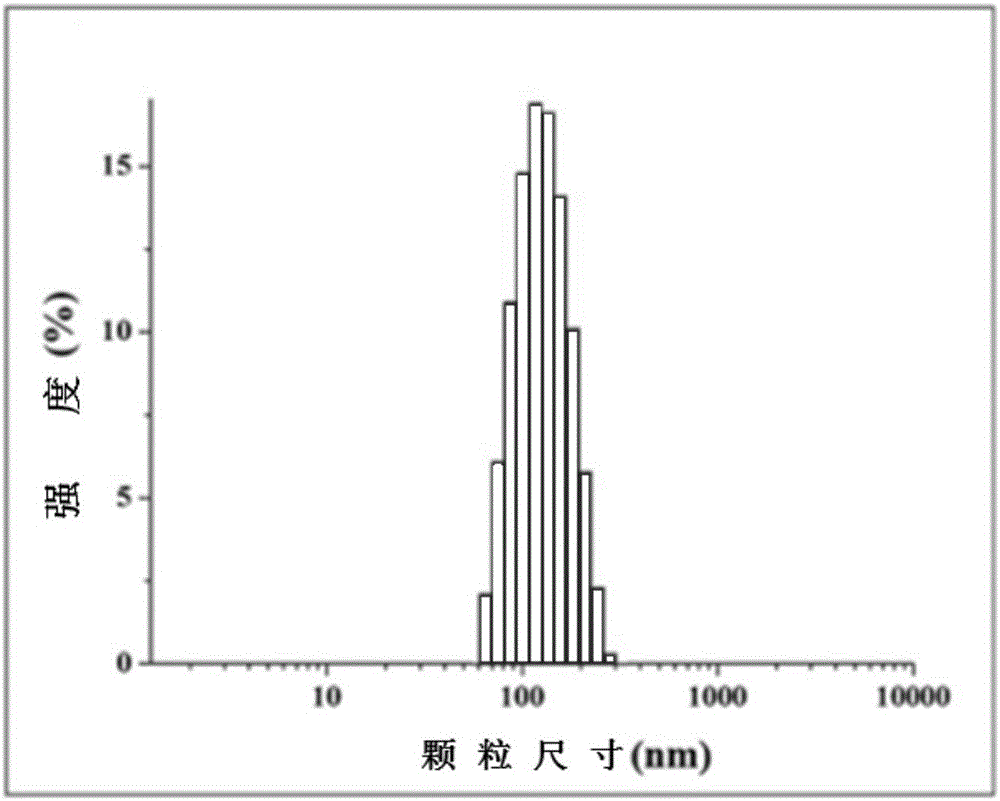

[0052] Embodiment 2 transmission electron microscopy and dynamic light scattering analysis verification

[0053] The particle size of the β-TCP particles prepared in Example 1 was observed by a H-7000 transmission electron microscope, and the acceleration voltage used was 75KV. The particle size of the prepared β-TCP particles was tested by dynamic light scattering. The Zetasizer Nano-ZS potential and particle size analyzer was used to determine the particle size and Zeta potential of polymer drugs. Particle size measurement parameters: He-Ne laser (wavelength 635nm), refractive index and viscosity are n=1.333 and η=0.933cp respectively, measurement temperature is 25°C. Potential measurement parameters: He-Ne laser (wavelength 635nm), scattering angle θ=14°, measurement temperature 25°C.

[0054] Observing the prepared nano-sized β-TCP particles by TEM, the particles are in irregular shape, and the particle size range is 20-160nm (such as figure 1 A, B). Observation by dyn...

Embodiment 3

[0055] The preparation of embodiment 3 polylactic acid / nanometer β-tricalcium phosphate composite material

[0056] 1) Weigh nano-sized β-TCP particles and PLA in proportion according to requirements, wherein the content of β-TCP is 10wt%, 30wt%, 50wt% respectively, prepare a composite solution with dichloromethane, stir and ultrasonically mix to obtain PLA / nano β-TCP complex solution, the solution is poured into a flat-bottomed glass dish, and vacuum-dried to obtain a PLA / nano β-TCP complex film;

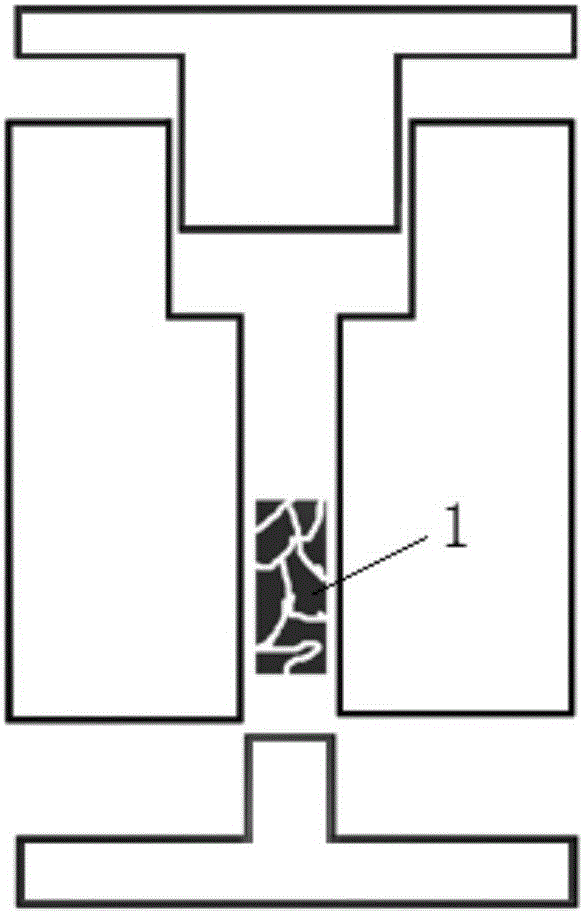

[0057] 2) Take the PLA / nano β-TCP composite film, melt and press it at 110°C and 260MPa to form a cylindrical parison of 10×20mm (diameter of the bottom surface×height), and hot press molding (the schematic diagram of hot pressing processing is shown in image 3 As shown, wherein 1 is a composite film, and the rest are processing molds), rapid cooling, and demoulding, the rods of high-strength PLA / nanometer β-TCP composite materials of different proportions can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com