Wastewater treatment method in turpentine production process

A production process and wastewater treatment technology, applied in the field of rosin wastewater treatment, can solve the problems such as difficulty in maintaining stable discharge of wastewater and unsatisfactory treatment effect, and achieve the effects of strong tolerance, strong decomposition and conversion ability, and improved multiplication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

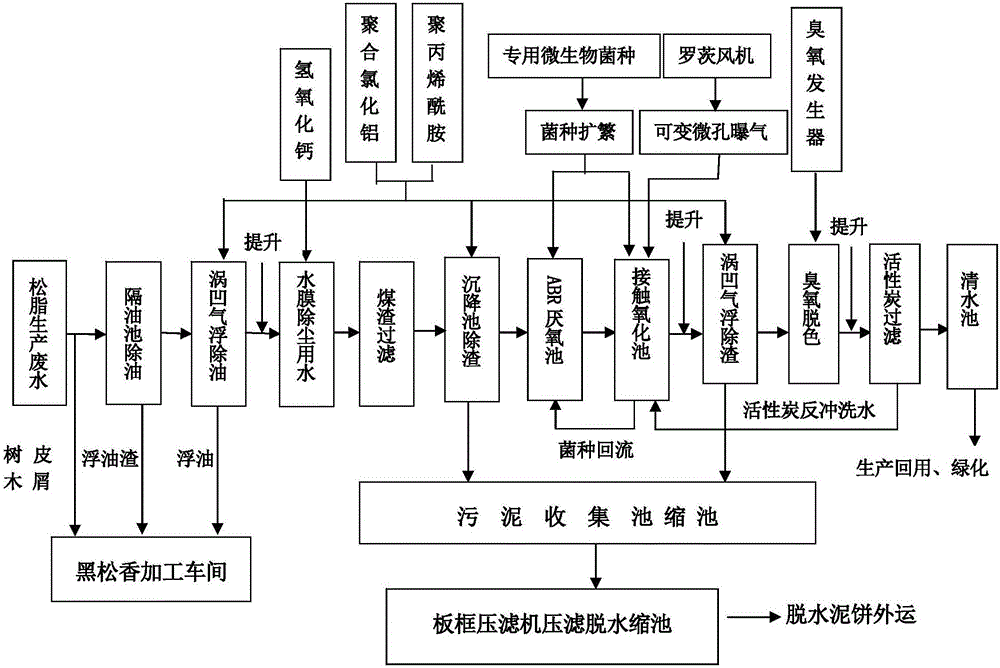

Image

Examples

Embodiment 1

[0029] 1. Early preprocessing

[0030] After the production wastewater is filtered by the pipe network, it enters the 9-stage grease trap. Each stage of the grease trap collects oil from the upper part, and the waste water enters the next stage from the lower part through the partition. A large amount of grease is mainly in the first and second grease traps. , needs to be extracted in time, and transported to the black rosin processing workshop to produce black rosin; the remaining floating oil in the grease trap is regularly opened by the ball valve and discharged into the low-level oil pollution collection tank for pumping to the black rosin processing workshop.

[0031] After the oil separation, the wastewater is lifted into the vortex air flotation system. This process requires the addition of 1-2‰ PAC flocculation demulsifier to promote the demulsification and separation of the emulsified oil in the wastewater. After being separated by the vortex air flotation system, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com