Composite piperazine organic amine desulfurizing agent

A technology of organic amines and desulfurizers, applied in gas treatment, membrane technology, dispersed particle separation, etc., to achieve the effects of good water solubility, large absorption capacity, and low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

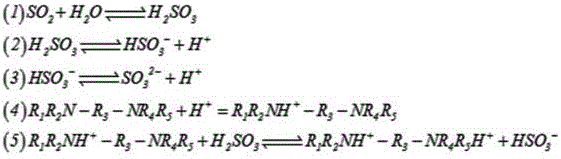

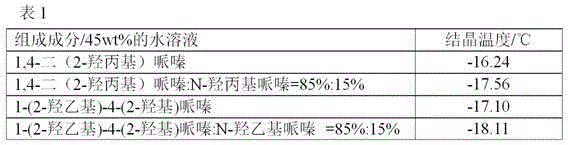

Method used

Image

Examples

Embodiment 1

[0034] Compound 40g of 1,4-bis(2-hydroxyethyl)piperazine with 10g of triethanolamine (the total amine concentration is 50%), add 40g of distilled water and stir to dissolve 0.1g of ethylene glycol siloxane. Add sulfuric acid to adjust the pH to 6.2, and then add distilled water to quantify to 100 g.

[0035] Take 50ml of the above solution for absorption at 50°C. After the absorption liquid reaches saturation, perform thermal desorption at 102°C. Control the total flow rate of the mixed gas to 500mL / min, SO 2 The concentration is 5000mg / m 3 .

[0036] The saturated absorption capacity of the composite desulfurizer in this example is 1.7059mol / L, while the saturated absorption capacity of 50% 1,4-bis(2-hydroxyethyl)piperazine aqueous solution is 1.5792mol / L when the desulfurizer is used. The saturated absorption of the desulfurizing agent has increased by 8.02%; the desorption rate of the composite desulfurizing agent in this example is 91.10%, while the desorption rate of 40...

Embodiment 2

[0038] Compound 20g of 1,4-bis(2-hydroxypropyl)piperazine with 2g of diethylenetriamine (the total amine concentration is 22%), add 5g of polypropylene glycol methyl ether and 0.1g of polyoxypropylene oxide ethylene glyceryl ether, Add 50 g of distilled water and stir to dissolve, add citric acid to adjust the pH to 6.2, then add distilled water to quantify to 100 g.

[0039] Take 50ml of the above solution for absorption at 50°C. After the absorption liquid reaches saturation, perform thermal desorption at 102°C. Control the total flow rate of the mixed gas to 500mL / min, SO 2 The concentration is 5000mg / m 3 . Absorption is carried out at 50°C, and after the absorption liquid reaches saturation, thermal desorption is carried out at 102°C, and the total flow rate of the mixed gas is controlled at 500mL / min, SO 2 The concentration is 5000mg / m 3 .

[0040] The saturated absorption capacity of the composite desulfurizing agent in this example is 0.8093mol / L, while the saturate...

Embodiment 3

[0042] Compound 25g of 1,4-bis(2-hydroxymethyl)piperazine with 15g of N-hydroxyethylpiperazine (the total amine concentration is 40%), add 5g of polyethylene glycol dimethyl ether and 0.1g of polydimethyl ether base siloxane, add 40g of distilled water and stir to dissolve, add phosphoric acid to adjust the pH to 6.2, then add distilled water to quantify to 100g.

[0043] Take 50ml of the above solution for absorption at 50°C. After the absorption liquid reaches saturation, perform thermal desorption at 102°C. Control the total flow rate of the mixed gas to 500mL / min, SO 2 The concentration is 5000mg / m 3 . Absorption is carried out at 50°C, and after the absorption liquid reaches saturation, thermal desorption is carried out at 102°C, and the total flow rate of the mixed gas is controlled at 500mL / min, SO 2 The concentration is 5000mg / m 3 .

[0044]The saturated absorption capacity of the composite desulfurizer in this example is 1.1991mol / L, while the saturated absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com