Method for preparing natural-cellulose based magnetic porous carbon and application of natural-cellulose based magnetic porous carbon

A natural cellulose and porous carbon technology, applied in chemical instruments and methods, other chemical processes, magnetic field/electric field shielding, etc., can solve the problems of magnetic porous carbon composite materials that have not been seen in literature and patent reports, and achieve excellent electromagnetic wave absorption The performance, equipment and process are simple, and the effect of realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of magnetic porous carbon based on natural cellulose, comprising the following steps:

[0044] (1) Put 10 grams of cotton fiber in 500 mL of 1 mol / L sodium hydroxide solution, soak for 4 hours to hydrolyze and activate the cellulose, and then wash the activated cotton with distilled water until pH=7, Filter and dry to obtain activated cellulose;

[0045] (2) Submerge 5 grams of activated cellulose obtained in step (1) in 250 mL of nickel nitrate solution with a concentration of 0.5 mol / L, stir magnetically for 24 hours, filter, and heat and dry under normal pressure to obtain a cellulose / metal salt mixture Precursor;

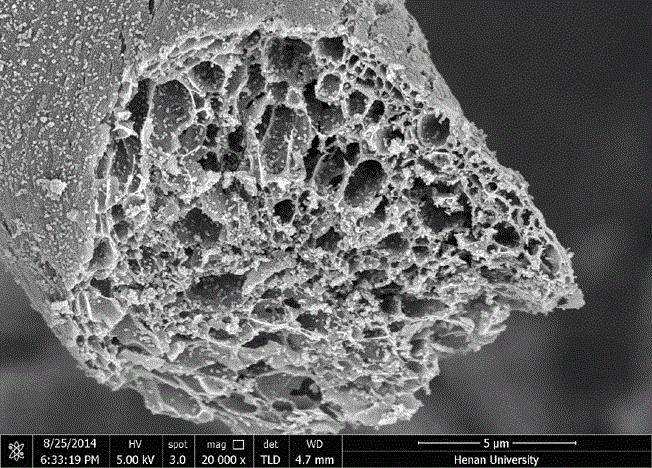

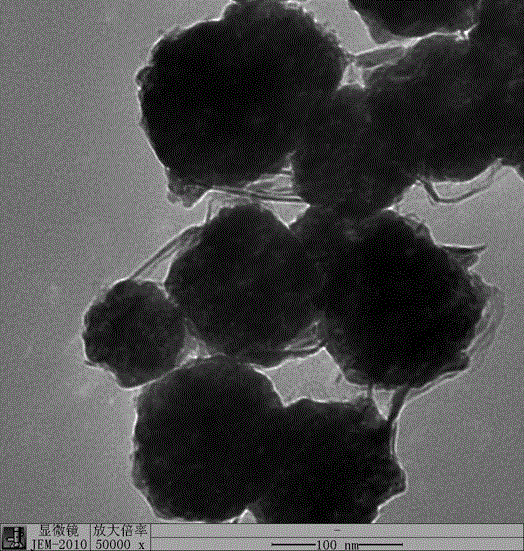

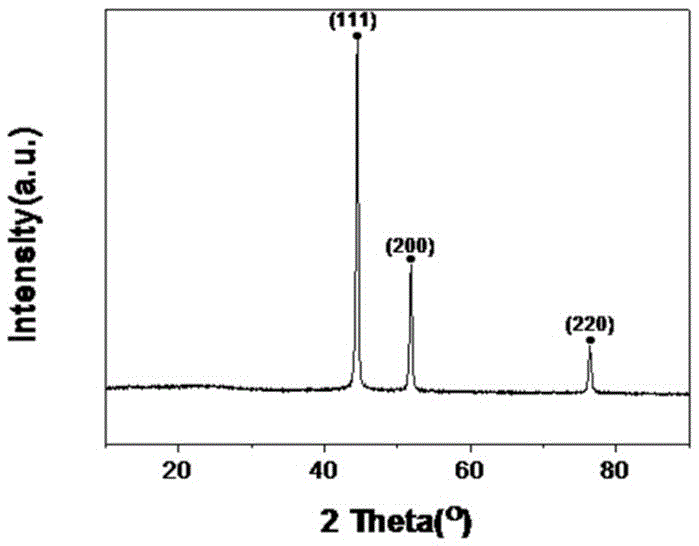

[0046] (3) Put the cellulose / metal salt mixture precursor obtained in step (2) into the cleaned ark, place the ark at the center of the quartz tube of the tube furnace, continuously feed ammonia gas, and adjust the tube furnace so that It is heated up to 800°C at a rate of 10°C / min, kept for 4 hours, then naturally cooled to room te...

Embodiment 2

[0051] A preparation method of magnetic porous carbon based on natural cellulose, comprising the following steps:

[0052] (1) Put 10 grams of flax in 500 mL of lithium hydroxide solution with a concentration of 2 mol / L, soak for 12 hours to hydrolyze and activate the cellulose, then wash the activated flax with distilled water until pH = 7, filter , drying to obtain activated cellulose;

[0053] (2) Submerge 5 grams of activated cellulose obtained in step (1) in 250 mL of cobalt acetate solution with a concentration of 0.5 mol / L, ultrasonicate for 30 minutes, continue mechanical stirring for 4 hours, filter, and heat and dry under normal pressure to obtain cellulose / Metal salt mixture precursor;

[0054] (3) Put the cellulose / metal salt mixture precursor obtained in step (2) into the cleaned ark, place the ark at the center of the quartz tube of the tube furnace, continuously feed ammonia gas, and adjust the tube furnace so that It is heated up to 800°C at a rate of 10°C / m...

Embodiment 3

[0057] A preparation method of magnetic porous carbon based on natural cellulose, comprising the following steps:

[0058] (1) Put 10 grams of ramie in 250 mL of 1 mol / L potassium hydroxide solution and soak for 4 hours to remove impurities on the surface of ramie and activate the cellulose by hydrolysis, and then dehydrate the activated ramie with distilled water Ramie is washed to pH=7, filtered and dried to obtain activated cellulose;

[0059] (2) Submerge 5 grams of activated cellulose obtained in step (1) in 250 mL of ferric nitrate solution with a concentration of 0.5 mol / L, stir mechanically for 8 hours, filter, and heat and dry under normal pressure to obtain a cellulose / metal salt mixture Precursor;

[0060] (3) Put the cellulose / metal salt mixture precursor obtained in step (2) into the cleaned ark, place the ark at the center of the quartz tube of the tube furnace, continuously feed ammonia gas, and adjust the tube furnace so that It is heated up to 800°C at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com