Nanoscale black phosphorus as well as preparation method and application thereof

A nanoscale, black phosphorus technology, applied in the preparation of phosphorus, nanotechnology, electrical components, etc., can solve the problems of low yield and yield of nanoscale black phosphorus, unfavorable large-scale production, long preparation time, etc., and achieves the preparation method. Simple and easy operation, low production cost, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment provides a kind of preparation method of nanoscale black phosphorus, it comprises the following steps:

[0047] Weigh 5 grams of red phosphorus blocks with a size of 0.1-0.3 cm in an argon-filled glove box, fill them with stainless steel balls with a diameter of 10 mm in a mass ratio of 1:20 into a 50 ml high-energy ball mill jar and Seal; the high-energy ball mill jar is placed in the high-energy ball mill, and the highest temperature is set to 60 degrees Celsius, the lowest temperature is set to 25 degrees Celsius, and then ball milled at 1500r / min for 2 hours to obtain 4.92 grams of nano-scale black phosphorus.

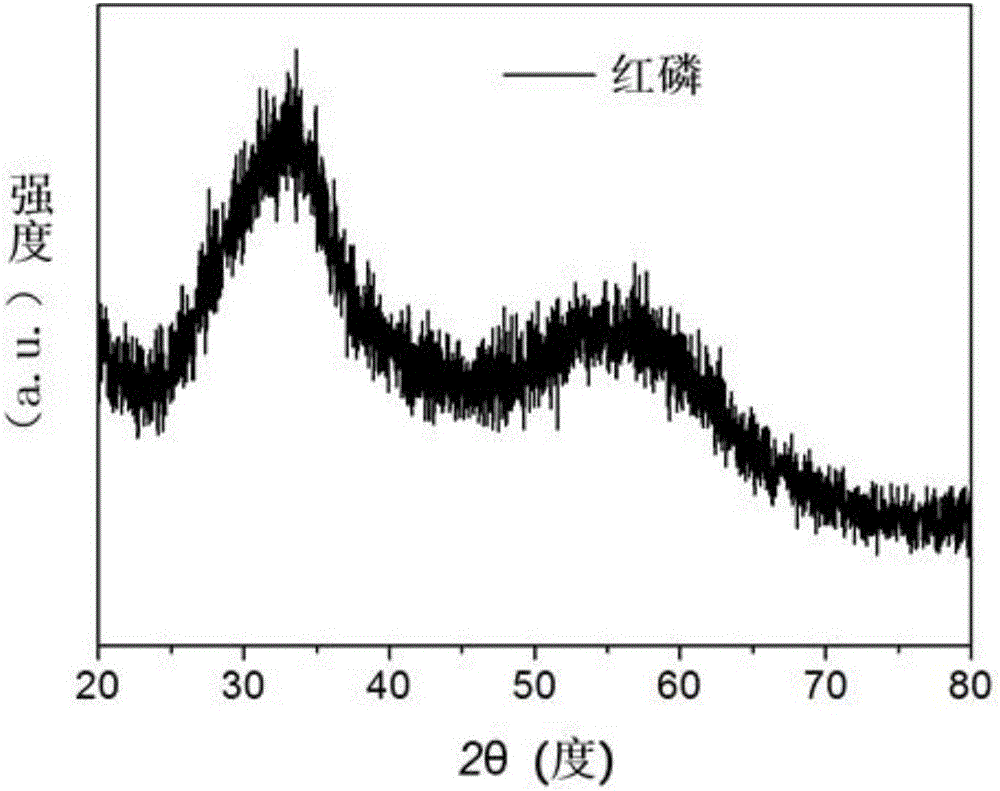

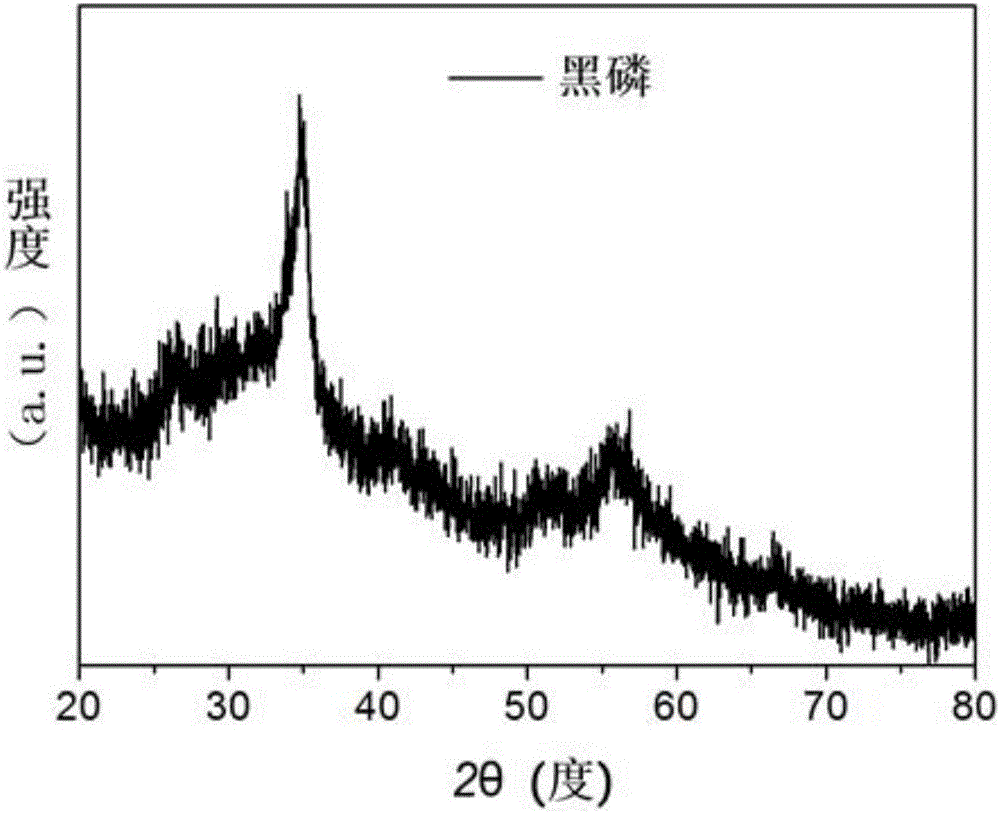

[0048] The nano-scale black phosphorus prepared in this embodiment is characterized, and compared with the red phosphorus raw material, the results are as follows Figure 1A-Figure 2B As shown, among them, Figure 1A and Figure 1B Respectively show the XRD figure of red phosphorus raw material and the black phosphorus that the presen...

Embodiment 2

[0050] The present embodiment provides a kind of preparation method of nanoscale black phosphorus, it comprises the following steps:

[0051] Weigh 3 grams of red phosphorus blocks with a size of 0.3-0.6 cm in an argon-filled glove box, fill them with stainless steel balls with a diameter of 10 mm in a mass ratio of 1:60 into a 50 ml high-energy ball mill jar and Seal; the high-energy ball mill jar is placed in a high-energy ball mill, and the highest temperature is set to 40 degrees Celsius, and the lowest temperature is set to 25 degrees Celsius, and then ball milled at 1200r / min for 5 hours to obtain 2.95 grams of nano-scale black phosphorus.

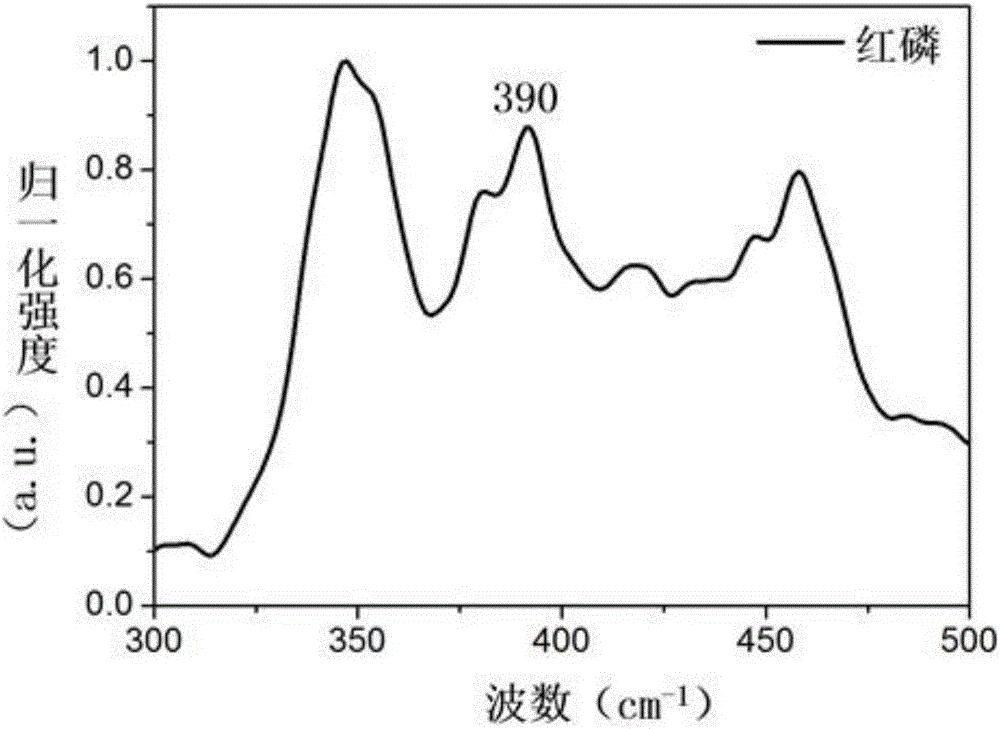

[0052] The nanoscale black phosphorus that present embodiment is made characterizes, and its result is as follows image 3 as shown, image 3 The Raman spectrum in shows that after the red phosphorus is ball-milled by the method of this example, the Raman peak at 390 wavenumber completely disappears, and a new Raman peak appears at ...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of nanoscale black phosphorus, it comprises the following steps:

[0055] Weigh 5 grams of red phosphorus blocks with a size of 0.3-0.6 cm in an argon-filled glove box, fill them with stainless steel balls with a diameter of 12 mm in a mass ratio of 1:30 into a 50 ml high-energy ball mill jar and Sealing; the high-energy ball mill jar is placed in the high-energy ball mill, and the highest temperature is set to 45 degrees Celsius, the lowest temperature is set to 25 degrees Celsius, and then ball milled at 1300r / min for 3.5 hours to obtain 4.96 grams of nano-scale black phosphorus.

[0056] The nanoscale black phosphorus that present embodiment is made characterizes, and its result is as follows Figure 4 , Figure 5 as shown, Figure 4 The Raman spectrum in shows that after the red phosphorus is ball-milled by the method of this example, the Raman peak at 390 wavenumber completely disappears, and a new Rama...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com