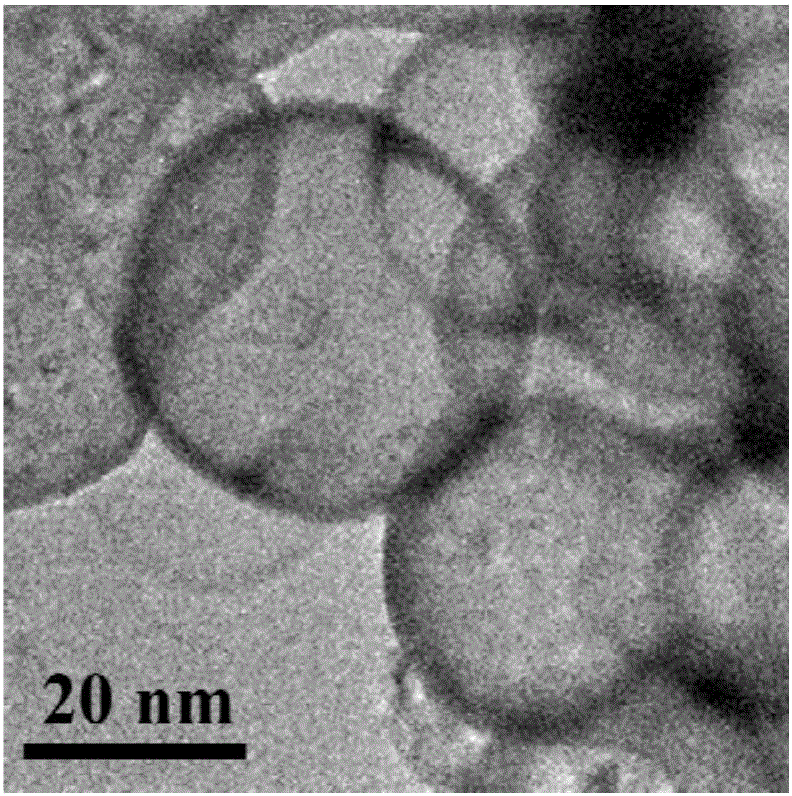

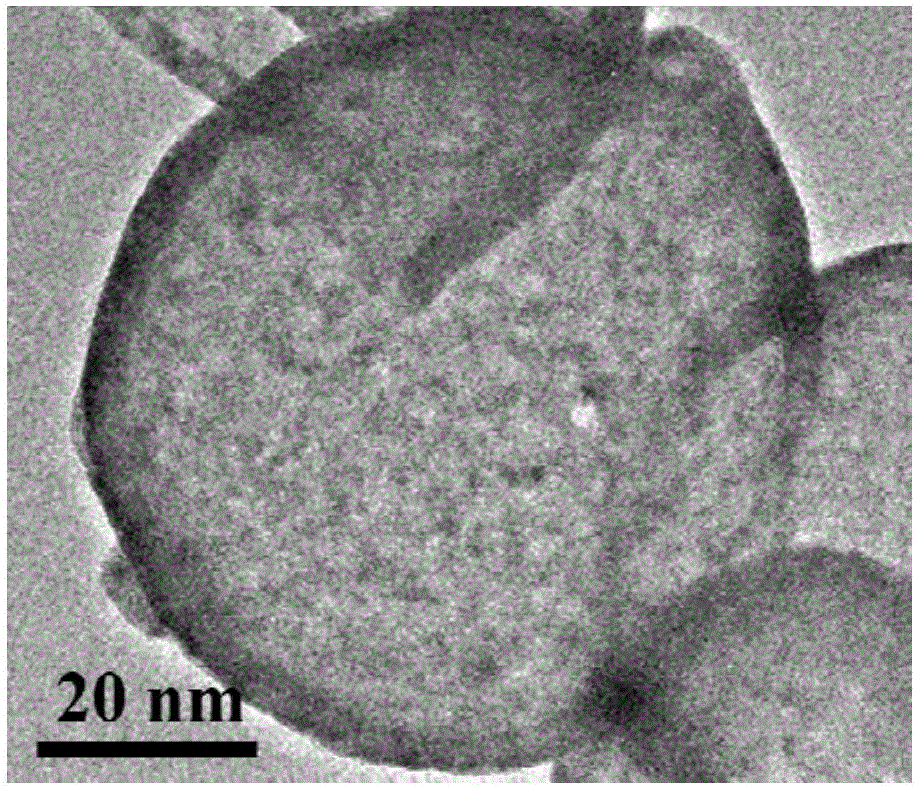

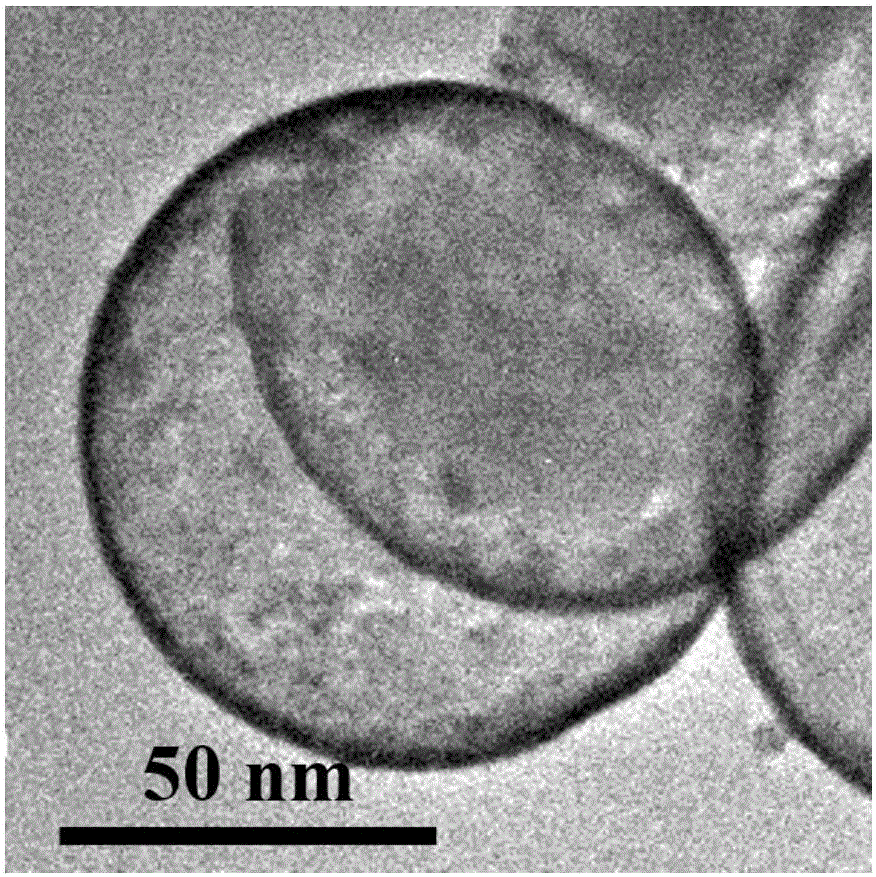

Method for preparing superfine hollow titanium dioxide nanospheres with diameter smaller than 100 nm

A technology of titanium dioxide and nanospheres, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve problems such as difficult to obtain, and achieve the effect of less reaction steps, low price, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of ultrafine hollow titanium dioxide nanospheres of the present invention includes the following steps:

[0025] s1. Provide a carbon nanosphere template with a particle size of 20-90nm;

[0026] s2. Disperse the nano-carbon sphere template in step s1 uniformly in absolute ethanol, and add a certain amount of deionized water to form a nano-carbon sphere sol system, and place it in a 60°C water bath with continuous high-speed stirring, then Under these conditions, a dilute solution of tetra-n-butyl titanate diluted with absolute ethanol was added dropwise, reacted for more than 2 hours to obtain CSs@TiO with controllable wall thickness and particle size 2 Sol

[0027] s3, CSs@TiO obtained in step s2 of centrifugation 2 Sol, the separated solids are dried, and then the agglomerates obtained after drying are calcined at a high temperature at a heating rate of 20°C / min or less, and the calcining temperature is 400-800°C, and heat preservation in a muffle fur...

Embodiment 1

[0040] s1. Take 20 mg of carbon nano sphere template with a particle size of 20-40 nm and disperse it in 60 mL of absolute ethanol to form a carbon nano sphere sol;

[0041] s2. Add the above nano carbon sphere sol to 120μL of deionized water, and continuously stir vigorously under the condition of 60℃ in a water bath, and then add dropwise the dilute solution of tetra-n-butyl titanate diluted with absolute ethanol (tetra-n-butyl titanate). 150μL of the original butyl ester solution dissolved in 20mL of absolute ethanol), after adding all the tetra-n-butyl titanate dilute solution, react for 2-10h to obtain nano CSs@TiO with controllable particle size and wall thickness 2 Sol

[0042] s3, the above nano CSs@TiO 2 The sol was centrifuged at a centrifugal speed of 30,000 r / min for 15 minutes to obtain solids;

[0043] s4. Put the above solids in a vacuum oven and treat them at 40°C for 12 hours to obtain dry solids;

[0044] s5. Place the above-mentioned dry solid in a muffle furnace, i...

Embodiment 2

[0047] s1. Take 20 mg of carbon nano sphere template with a particle size of 30-60 nm and disperse it in 60 mL of absolute ethanol to form a carbon nano sphere sol;

[0048] s2. Add the above nano carbon sphere sol to 120μL of deionized water, and continuously stir vigorously under the condition of 60℃ in a water bath, and then add dropwise the dilute solution of tetra-n-butyl titanate diluted with absolute ethanol (tetra-n-butyl titanate). 150μL of the original butyl ester solution dissolved in 20mL of absolute ethanol), after adding all the tetra-n-butyl titanate dilute solution, react for 2-10h to obtain nano CSs@TiO with controllable particle size and wall thickness 2 Sol

[0049] s3, the above nano CSs@TiO 2 The sol was centrifuged at a centrifugal speed of 30,000 r / min for 15 minutes to obtain solids;

[0050] s4. Put the above solids in a vacuum oven and treat them at 40°C for 12 hours to obtain dry solids;

[0051] s5. Place the above-mentioned dry solid in a muffle furnace, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com