Method for reinforcing sludge dewatering performance by means of micro-bubble/flocculating agent coupling

A sludge dewatering and micro-bubble technology, applied in the field of environmental engineering, can solve problems such as environmental pollution, secondary pollution, poor sludge dewatering performance, etc., and achieve the effects of low cost, cost saving, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

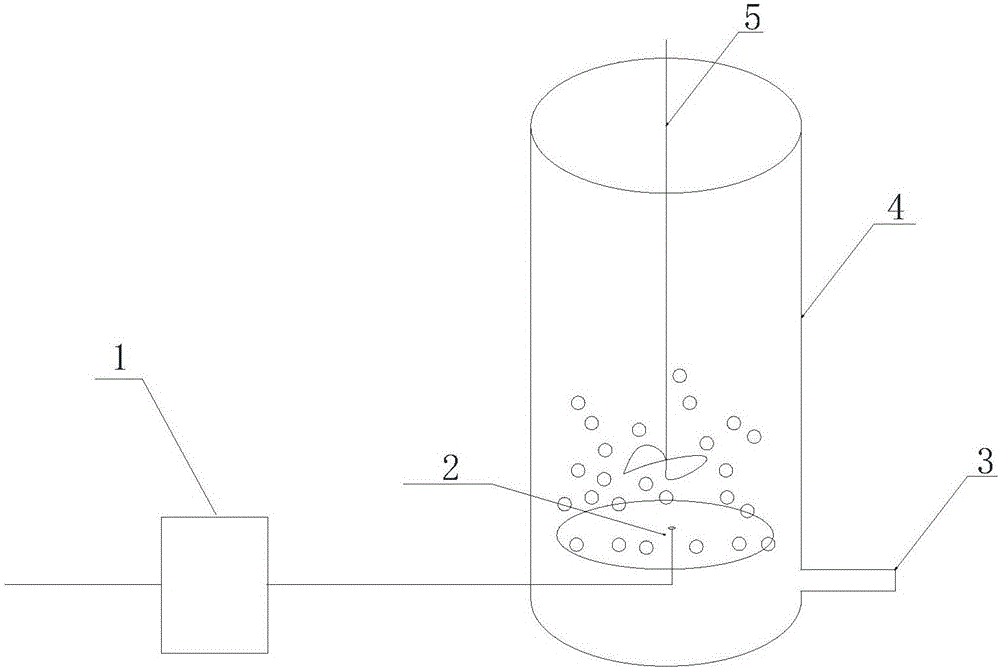

Image

Examples

Embodiment 1

[0027] This embodiment relates to a method for microbubble / PAM coupling to strengthen sludge dewatering performance, which includes the following steps:

[0028] Take liquid sludge with a concentration of 15g / L from a sewage treatment plant in Shanghai, and perform microbubble treatment. The diameter of microbubbles is 10μm, and the treatment time is 30 minutes. Then add 0.1% to the sludge after microbubble treatment. The PAM (sludge dry weight), using a magnetic stirrer to stir, first carry out rapid stirring (100r / min) for 3min, and then carry out slow stirring (35r / min) for 10min, after stirring evenly, the capillary water absorption time of the sludge ( CST) was reduced by 35% compared with untreated sludge, and the amount of PAM was reduced by 0.5 times compared with that of PAM conditioning alone.

Embodiment 2

[0030] This embodiment relates to a method for microbubble / PAM coupling to strengthen sludge dewatering performance, which includes the following steps:

[0031] Take the liquid sludge with a concentration of 30g / L from a sewage treatment plant in Shanghai for micro-bubble treatment. The diameter of the micro-bubbles is 50 μm, and the treatment time is 120 minutes. Then add 0.5% to the sludge after micro-bubble treatment. The PAM (sludge dry weight), using a magnetic stirrer to stir, first carry out rapid stirring (250r / min) for 5min, and then carry out slow stirring (55r / min) for 15min, after stirring evenly, the capillary water absorption time of the sludge ( CST) was reduced by 65% compared with untreated sludge, and the amount of PAM was reduced by 1.0 times compared with PAM conditioning alone.

Embodiment 3

[0033] This embodiment relates to a method for microbubble / PAM coupling to strengthen sludge dewatering performance, which includes the following steps:

[0034] Take the liquid sludge with a concentration of 20g / L from a sewage treatment plant in Shanghai for micro-bubble treatment. The diameter of the micro-bubbles is 20μm, and the treatment time is 45 minutes. Then add 0.2% to the sludge after micro-bubble treatment. The PAM (sludge dry weight), using a magnetic stirrer to stir, first carry out rapid stirring (150r / min) for 4min, and then carry out slow stirring (45r / min) for 12min, after stirring evenly, the capillary water absorption time of the sludge ( CST) was reduced by 40% compared with untreated sludge, and the amount of PAM was reduced by 0.7 times compared with that of PAM conditioning alone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com