Alkynyl quaternary ammonium salt multifunctional surfactants and preparation method thereof

The technology of surfactant and quaternary ammonium salt is applied in the field of oilfield production stimulation and multifunctional surfactant, which can solve the problems of water pollution and eutrophication of water source, and achieve the effect of increasing corrosion inhibition performance and good corrosion inhibition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

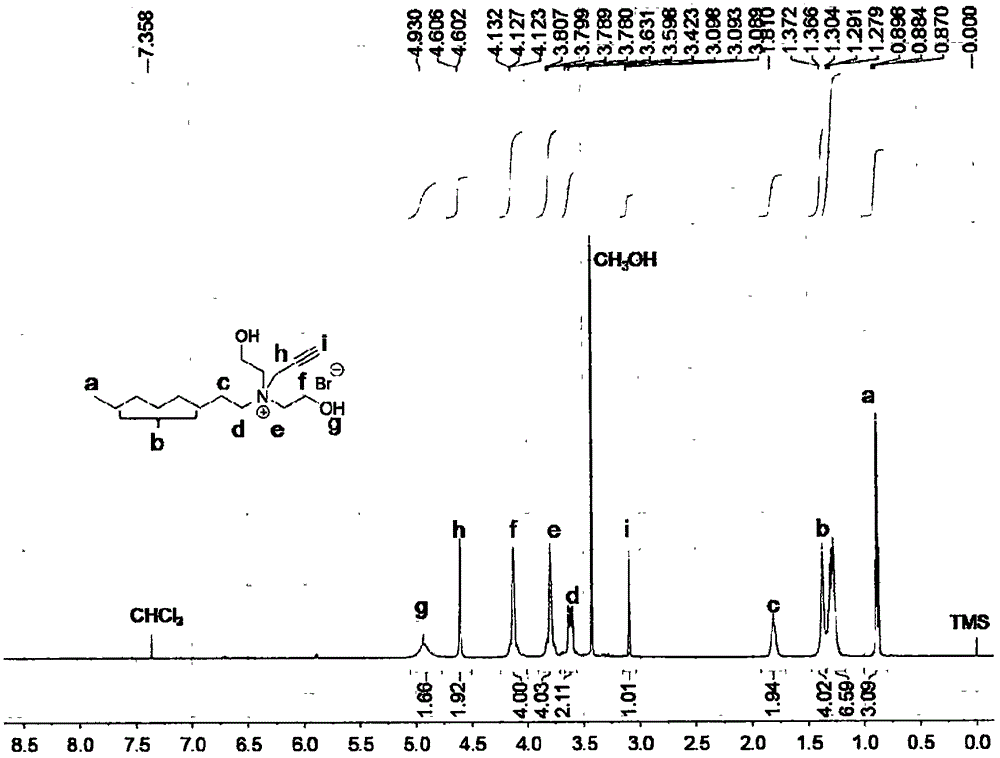

[0032] The preparation of embodiment 1 butyl alkynyl quaternary ammonium salt surfactant C4

[0033] (1) 1-bromobutane (4.2g, 30mmol), diethanolamine (4.73g, 45mmol), anhydrous potassium carbonate (8.29g, 60mmol) and potassium iodide (1.0g) were added in a 250mL two-necked bottle, and 80mL of acetonitrile was added, Nitrogen was passed for 5 minutes to replace the air in the system, and then refluxed for 12 hours.

[0034] (2) Stop the reaction, remove acetonitrile by rotary evaporation, add 60 mL of dichloromethane and 60 mL of water, and separate the layers. The organic phase was washed twice with water in order to remove excess diethanolamine. The product has certain solubility in water, and after washing with water, the aqueous phase is extracted twice with dichloromethane. The organic phase was separated and dried over anhydrous sodium sulfate.

[0035] (3) The dichloromethane was removed by rotary evaporation to obtain 3.23 g of light yellow liquid with a yield of 66....

Embodiment 2

[0038] (6) Dichloromethane:methanol=10:1, the pure product C4 was obtained by silica gel column chromatography as light yellow oily liquid, which was used for subsequent tests. The preparation of embodiment 2 benzyl alkynyl quaternary ammonium salt surfactant Bz

[0039] (1) Add benzyl chloride (1.90g, 15mmol), diethanolamine (2.4g, 23mmol), anhydrous potassium carbonate (4.28g, 30mmol) and potassium iodide (0.5g) into a 250mL two-necked bottle, add 80mL of acetonitrile, and blow nitrogen for 5 Minutes, replace the air in the system, and then reflux for 12h.

[0040] (2) Stop the reaction, remove acetonitrile by rotary evaporation, add 30 mL of dichloromethane and 30 mL of water, and separate the layers. The organic phase was washed twice with water in order to remove excess diethanolamine. The product has certain solubility in water, and after washing with water, the aqueous phase is extracted twice with dichloromethane. The organic phase was separated and dried over anhyd...

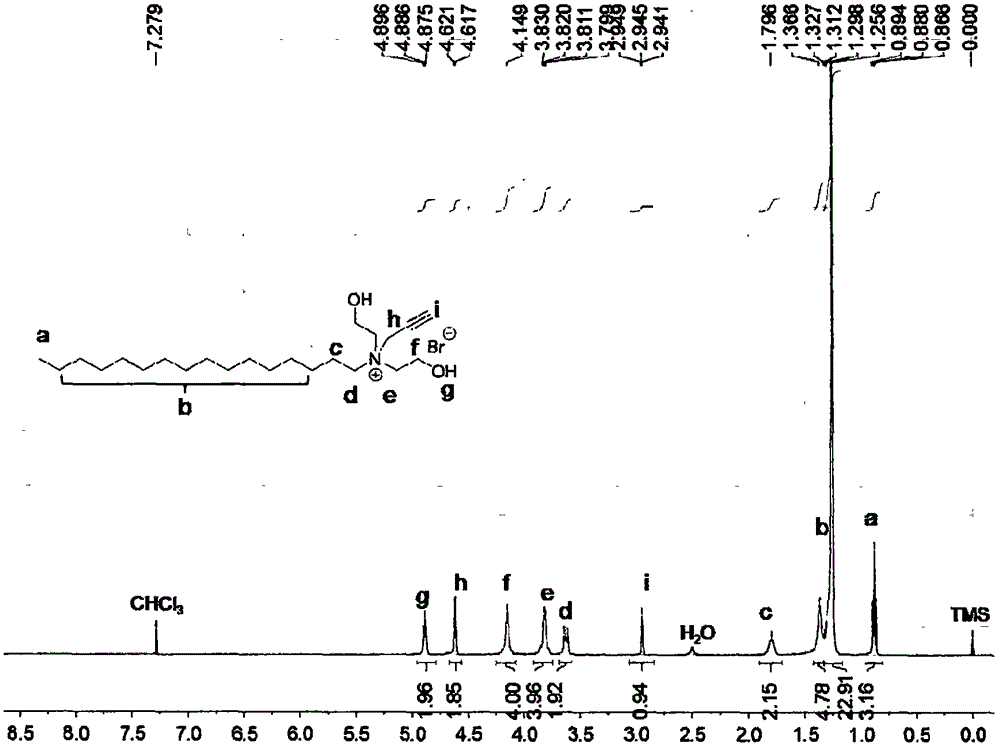

Embodiment 3

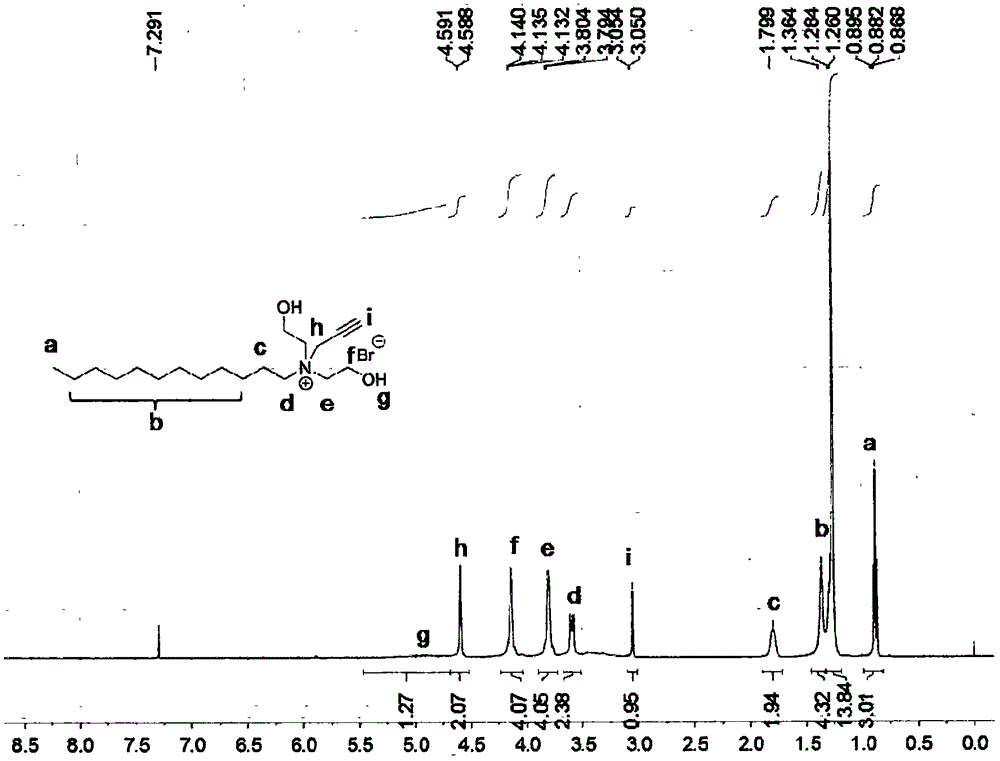

[0044] The preparation of embodiment 3 n-octyl alkynyl quaternary ammonium salt surfactant C8

[0045] (1) n-octyl bromide (6.0g, 30mmol), diethanolamine (4.73g, 45mmol), anhydrous potassium carbonate (8.29g, 60mmol) and potassium iodide (1.0g) were added in a 250mL two-necked bottle, and 80mL of acetonitrile was added, and the Nitrogen for 5 minutes to replace the air in the system, and then reflux for 12 hours.

[0046](2) Stop the reaction, remove acetonitrile by rotary evaporation, add 60 mL of dichloromethane and 60 mL of water, and separate the layers. The organic phase was washed twice with water in order to remove excess diethanolamine. The product has certain solubility in water, and after washing with water, the aqueous phase is extracted twice with dichloromethane. The organic phase was separated and dried over anhydrous sodium sulfate.

[0047] (3) Dichloromethane was removed by rotary evaporation to obtain 5.00 g of light yellow liquid with a yield of 76.7%. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com