Method for preparing thermo-sensitive polymer PNIPAM film through plasma-induced solution polymerization

A temperature-sensitive polymer and plasma technology, which is applied in the field of preparing temperature-sensitive polymer PNIPAM film, can solve the problems of unstable chemical properties, complicated process, and easy-to-destroy appearance, so that the appearance is not easy to be destroyed, The effect of simple process and single ingredient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

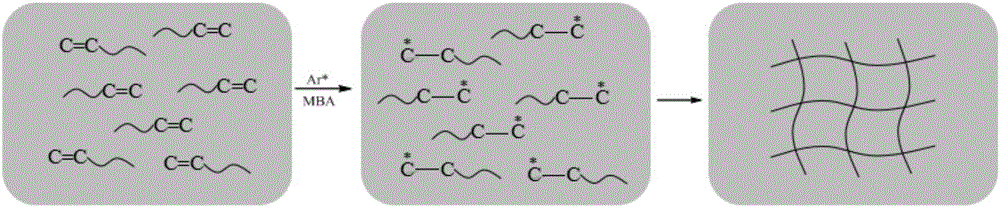

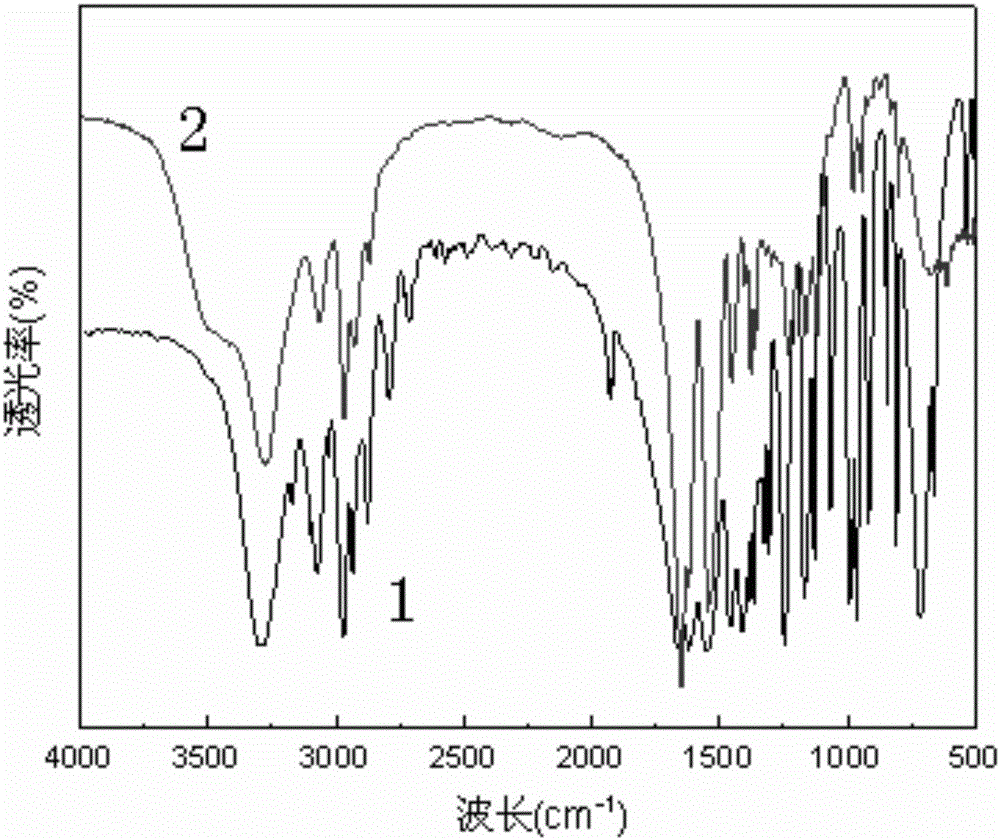

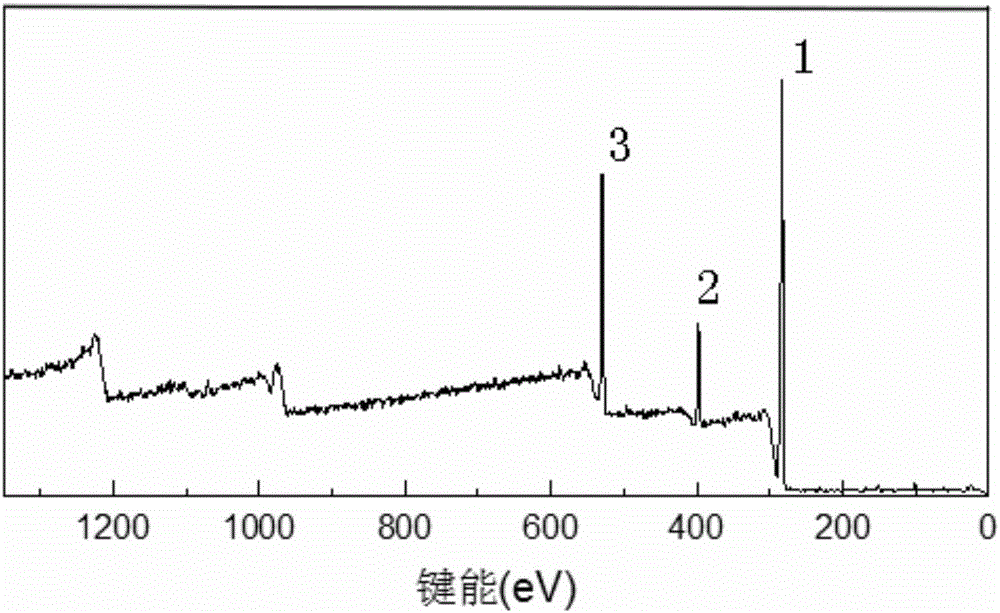

[0023] Specific embodiment one: the method for the preparation of temperature-sensitive polymer PNIPAM membrane by a kind of plasma-initiated solution polymerization of this embodiment, realizes according to the following steps:

[0024] 1. Take 0.1-0.3g N-isopropylacrylamide crystal, dissolve it in 4-6mL ultrapure water, add 0.004-0.04g N,N-methylenebisacrylamide;

[0025] 2. Use a syringe to take 0.2-0.3mL of the solution prepared in step 1, spread it evenly on the surface of the glass substrate, then place it in a quartz reactor, seal it, and pass it into argon gas at a flow rate of 0-1L / min;

[0026] 3. Place the quartz reaction kettle in step 2 between the two poles of the plasma generator, adjust the voltage to 0-45V, and discharge at high voltage for 0-5 minutes to obtain a film visible to the naked eye, and then wash off the unreacted monolayer with ultrapure water. The body solution was vacuum-dried for 5-7h to complete the preparation of the temperature-sensitive pol...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, take 0.2g of N-isopropylacrylamide crystals, dissolve them in 5mL of ultrapure water, add 0.03g of N,N-methylene bis Acrylamide. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, take 0.25 mL of the solution prepared in Step 1 with a syringe, and spread it evenly on the surface of the glass substrate. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com