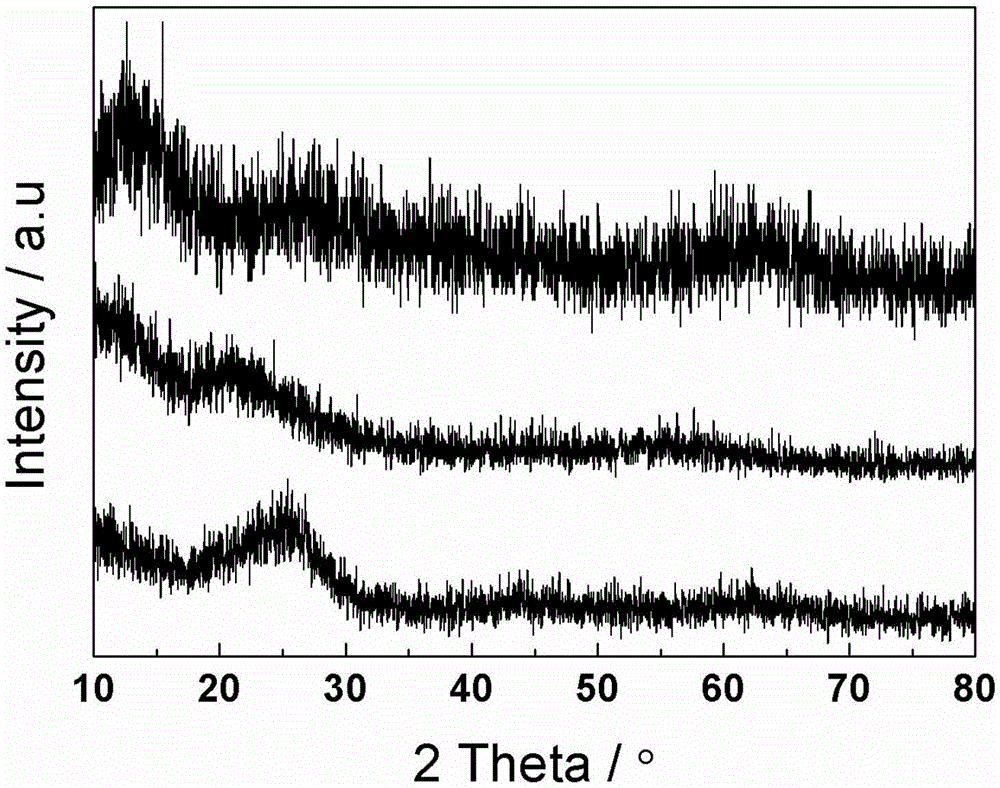

Method for preparing nitrogen-doped porous spherical disordered carbon material

A porous spherical, disordered carbon technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of sodium ion intercalation and extraction difficulties, and achieve good cycle stability, high specific surface area, and high specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

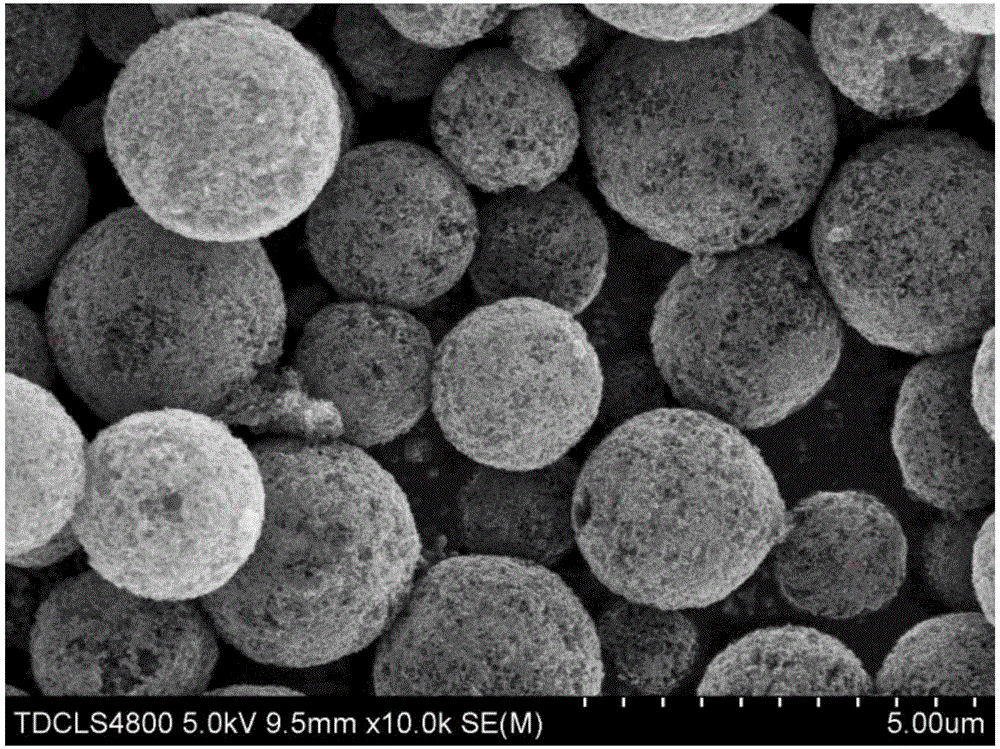

Embodiment 1

[0041] 1). Dissolving 22.5g glycine into 1000mL deionized water to prepare a glycine solution with a concentration of 0.3mol / L;

[0042] 2). Put 4.5g SiO 2 Added to the glycine solution, magnetically stirred (10r / s), to obtain a milky white suspension;

[0043] 3). The milky white suspension prepared above is spray-dried at a drying temperature of 160°C;

[0044] 4). The above-mentioned spray-dried product was pyrolyzed under an argon atmosphere, the pyrolysis temperature was 700°C, the heating rate was 10°C / min, and the temperature was kept for 120min;

[0045] 5). Add the pyrolysis product to 100mL NaOH solution with a concentration of 1mol / L for boiling etching, and the etching time is 6h;

[0046] 6). The etching product was washed 5 times with deionized water, and dried at 100° C. for 24 hours to obtain the final product.

[0047] Use the obtained nitrogen-doped porous spherical disordered carbon material to make the negative electrode of the sodium ion battery, and as...

Embodiment 2

[0050] 1). Dissolving 30g of glycine into 1000mL of deionized water to prepare a glycine solution with a concentration of 0.4mol / L;

[0051] 2). Put 18g SiO 2 Add it into the glycine solution and stir (15r / s) to obtain a milky white suspension;

[0052] 3). The milky white suspension prepared above is spray-dried at a drying temperature of 180°C;

[0053] 4). The above-mentioned spray-dried product was pyrolyzed under an argon atmosphere, the pyrolysis temperature was 800°C, the heating rate was 6°C / min, and the temperature was kept for 90min;

[0054] 5). Add the pyrolysis product to 70 mL of NaOH solution with a concentration of 3 mol / L for boiling etching, and the etching time is 5 hours;

[0055] 6). The etching product was washed 7 times with deionized water, and dried at 100° C. for 36 hours to obtain the final product.

[0056] Use the obtained nitrogen-doped porous spherical disordered carbon material to make the negative electrode of the sodium ion battery, and ass...

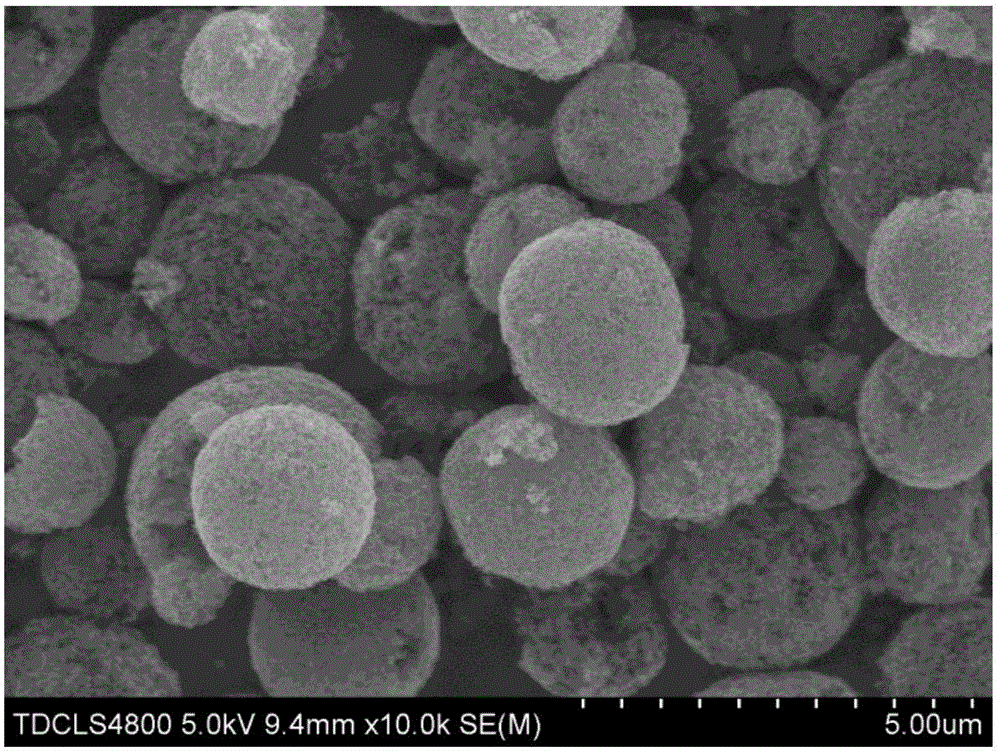

Embodiment 3

[0059] 1). Dissolving 30g of glycine into 1000mL of deionized water to prepare a glycine solution with a concentration of 0.4mol / L;

[0060] 2). Add 30g SiO 2 Added to the glycine solution, magnetically stirred (15r / s) to obtain a milky white suspension;

[0061] 3). The milky white suspension prepared above is spray-dried at a drying temperature of 180°C;

[0062] 4). The above-mentioned spray-dried product was pyrolyzed under an argon atmosphere, the pyrolysis temperature was 800°C, the heating rate was 6°C / min, and the temperature was kept for 90min;

[0063] 5). Add the pyrolysis product to 70 mL of NaOH solution with a concentration of 3 mol / L for boiling etching, and the etching time is 5 hours;

[0064] 6). The etching product was washed 7 times with deionized water, and dried at 100° C. for 36 hours to obtain the final product.

[0065] Use the obtained nitrogen-doped porous spherical disordered carbon material to make the negative electrode of the sodium ion batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com