Hydrothermal lithium iron phosphate carbon coating method

A method of lithium iron phosphate and lithium iron phosphate technology, which is applied in the field of lithium ion battery cathode material preparation technology, can solve the problems of low product tap density electrode compaction density, uneven carbon layer, poor conductivity, etc., and achieve excellent electrical conductivity. Good chemical properties, uniform composition, and good batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

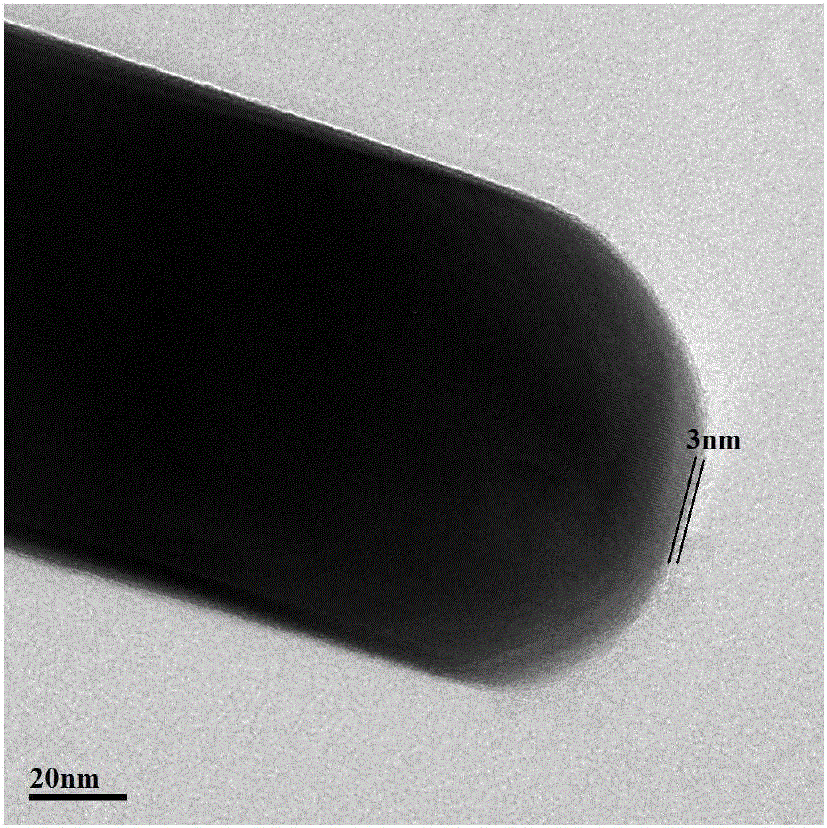

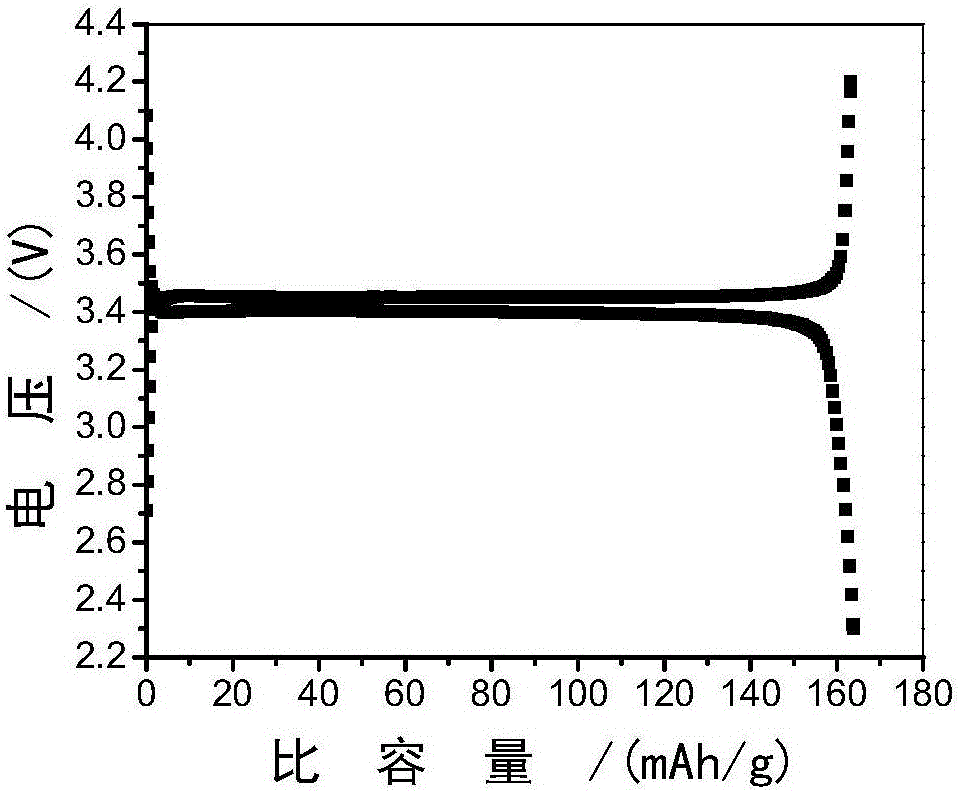

Embodiment 1

[0028] According to patent ZL201010031395.3, white powder of lithium iron phosphate is prepared. The specific steps are as follows: dissolve and dilute 555.7g of ferrous sulfate heptahydrate (2mol) to 2.0L; dilute 237.4g of 85% phosphoric acid (2.06mol) to 0.5L; dissolve 251.8g of lithium hydroxide monohydrate (6mol) Dilute to 1.5L in water. Put the phosphoric acid solution and lithium hydroxide solution into a 5L autoclave with a sealed feeding tube and a cooling coil, purge the autoclave with inert gas (nitrogen) to make all the air escape, seal the autoclave, and heat from room temperature with stirring at 200rpm When the temperature reaches 40°C, open the feed valve and exhaust valve, and add the ferrous sulfate solution prepared above with stirring at a feed rate of 300 mL / min. Seal the autoclave, stir for 20 minutes, open the feed valve and exhaust valve, and then add the prepared lithium hydroxide solution as a pH adjuster. The solution is prepared by dissolving 8g of l...

Embodiment 2

[0031] Example 2 (Compared with Example 1, the degree of oxidation is different)

[0032] Put the lithium iron phosphate powder in Example 1 in an electric heating blast drying box, keep it at 180℃ for 1h, take it out, and measure Fe 3+ The content is 2.0%. The other steps are the same as in Example 1. The electrochemical performance, carbon content and ferric iron content of the product are shown in Table 1.

Embodiment 3

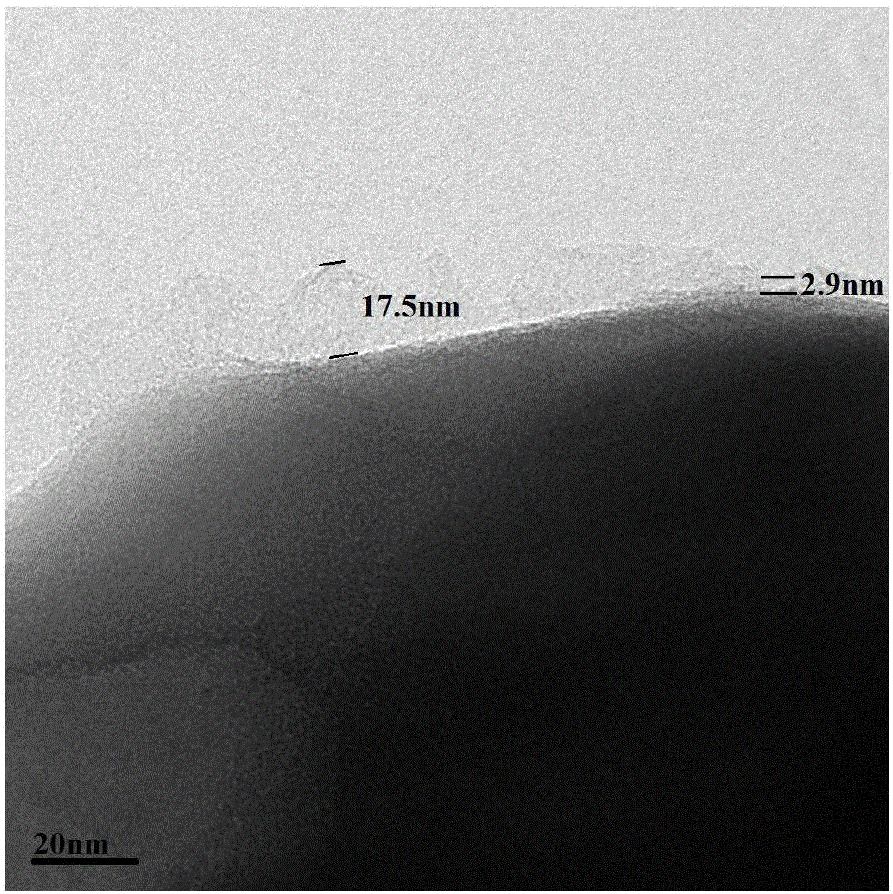

[0037] Example 3 (Olefin ratio 1:7)

[0038] The oxidized lithium iron phosphate powder in Example 1 was placed in a tube furnace, and high-purity argon was first introduced. In a high-purity argon atmosphere, the heating rate was controlled to 4°C / min and heated from room temperature to 570°C. , And keep it for 2h, continue to increase the temperature in the furnace to 630℃ at a heating rate of 4℃ / min, then change to a reaction gas with a volume ratio of 2-butene to argon of 1:7, and control the gas flow to 50mL / min , 4h later, switch the gas to high-purity argon again, and cool to below 100℃ to obtain LiFePO 4 / C Composite materials. The electrochemical performance, carbon content and ferric iron content of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com