Gelatin/gellan gum/hydroxyapatite composite hydrogel and preparation method thereof

A composite hydrogel and hydroxyapatite technology, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of large cell toxicity, difficulty in complete degradation, unfavorable tissue cell attachment and proliferation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

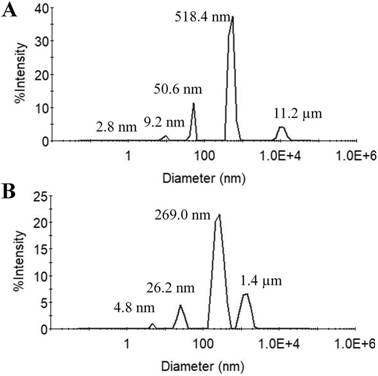

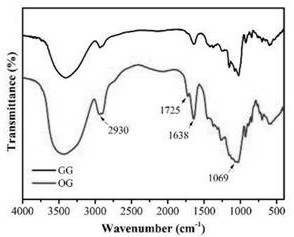

[0056] Example 1 Preparation and Characterization of Oxidized Gellan Gum

[0057] One, the preparation method of oxidized gellan gum

[0058] The preparation process of oxidized gellan gum (OG) is as follows:

[0059] (1) Weigh a certain amount of low-acyl gellan gum (GG), disperse it in 200 mL of distilled water at 90 °C, stir for 30 min to obtain a uniform GG solution, and gradually cool down to 40 °C.

[0060] (2) Add a certain amount of NaIO to the GG solution 4 , under the condition of avoiding light, control the oxidation temperature and oxidation time, and vigorously stir to obtain the oxidized gellan gum mixture.

[0061] (3) Pour the oxidized gellan gum mixture into the dialysis bag, the molecular weight of the dialysis bag cut-off molecule is 8-14kDa, dialyze with distilled water at room temperature for 5 days to remove the residual NaIO 4 With reaction by-products, the mixed solution after dialysis is suction-filtered, and the solution obtained by suction filtrat...

Embodiment 2

[0079] Example 2 Preparation and Characterization of Aminated Hydroxyapatite

[0080] 1. Preparation of Aminated Hydroxyapatite

[0081] The preparation process of aminated hydroxyapatite includes the synthesis of hydroxyapatite (Hap) and the process of preparing aminated hydroxyapatite (mHap) from hydroxyapatite. The specific process is as follows:

[0082] (1) Synthesis of hydroxyapatite

[0083] (1) Dissolve calcium nitrate and diammonium hydrogen phosphate in distilled water respectively to obtain 1.2M Ca 2+ solution, 0.72M HPO 4 2- solution.

[0084] (2) At 40°C, the Ca 2+ The solution is slowly dropped into HPO according to the volume ratio of 1:1 4 2- In the solution, at the same time, ammonia water was used to stabilize the pH of the mixed solution at 10.5, and the reaction was continued for 2 hours.

[0085] (3) Let the reaction solution stand at 50°C for 12 hours, collect the white precipitate by centrifugation, wash the precipitate with absolute ethanol and ...

Embodiment 3

[0109] Example 3 Preparation and Characterization of Gelatin / Oxidized Gellan Gum Hydrogel

[0110] One, the preparation method of gelatin / oxidized gellan gum hydrogel

[0111] The gelatin / oxidized gellan gum (Gel-OG) hydrogel was prepared as follows:

[0112] (1) Weigh 1 g of Gel and dissolve it in distilled water at 50°C to prepare a 20 wt% Gel solution.

[0113] (2) Weigh a certain amount of OG and dissolve it in distilled water at 40°C to prepare 1wt%, 1.5wt%, 2wt%, 2.5wt% and 3wt% OG solutions respectively; among them, oxidized gellan gum (OG) Prepared by the conditions optimized in Example 1, that is, GG and NaIO in the preparation process of OG 4 The mass ratio is 1:0.9, the oxidation temperature is 40°C, and the oxidation time is 8h.

[0114] (3) Mix different concentrations of OG solution and Gel solution at a mass ratio of 1:1 at 40°C.

[0115](4) Pour the mixed solution into five glass test tubes, each of which has an inner diameter of 13mm and a depth of 100mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive stress | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com