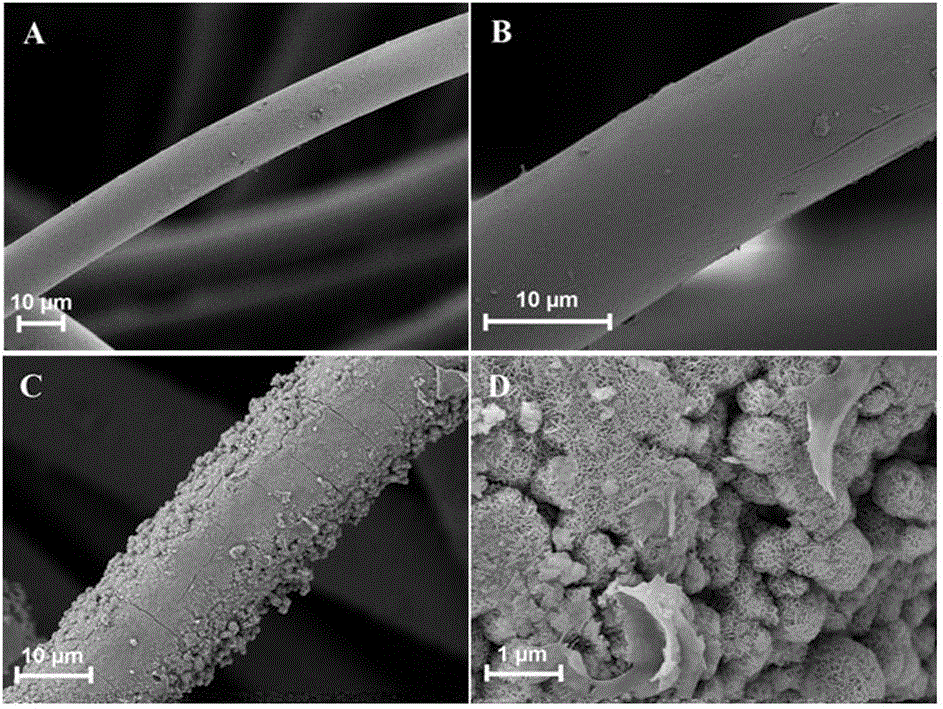

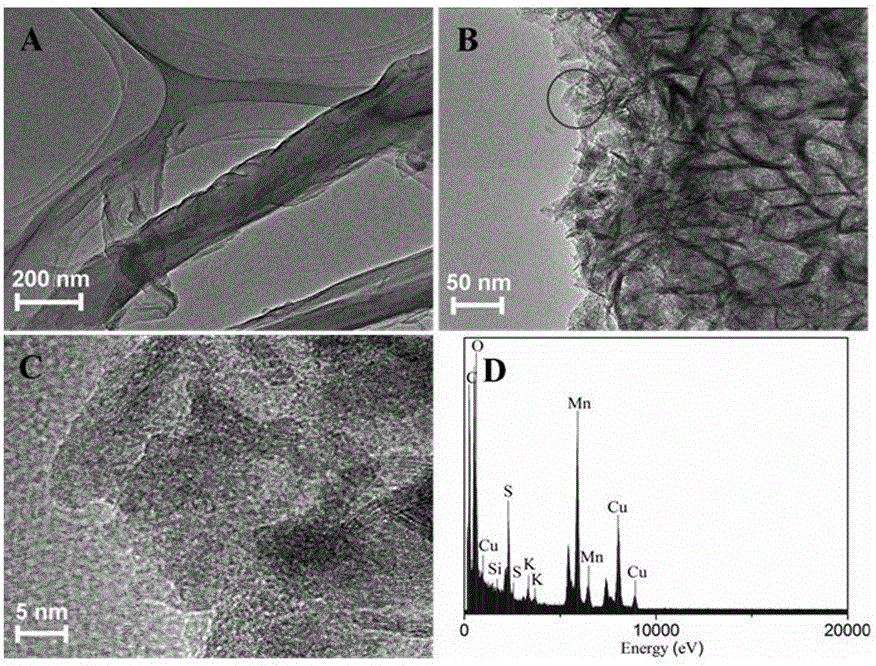

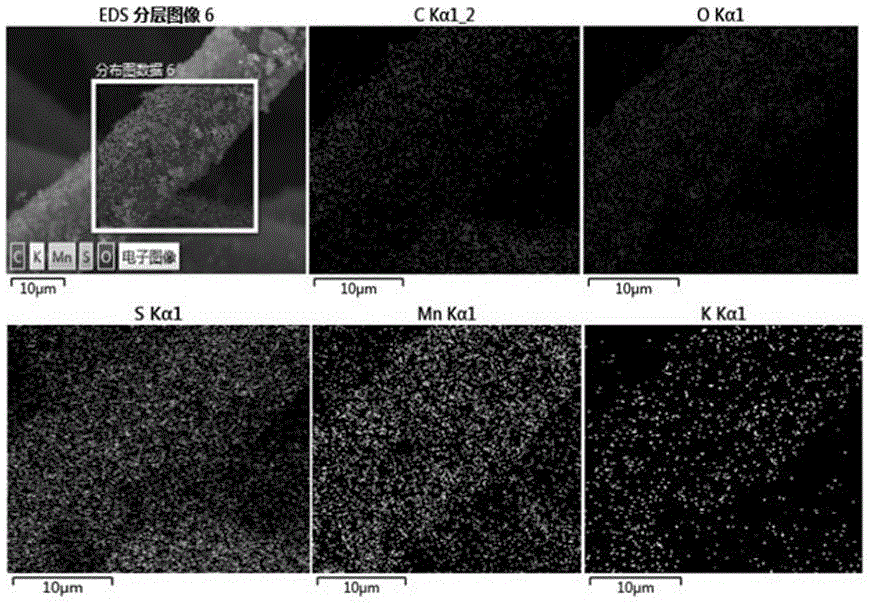

Method for in-situ generation of nano-flower-shaped manganese dioxide catalyst on filter material

A manganese dioxide, in-situ generation technology, applied in the direction of manganese oxide/manganese hydroxide, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the binding force between catalyst and filter fiber Weak, uneven catalyst loading, affecting the air permeability of the filter material, etc., to achieve the effects of excellent air permeability and catalytic stability, easy operation, and high pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of method that in situ generates nano flower shape manganese dioxide catalyst on filter material, comprises the following steps:

[0030] a) Add 0.042g of sodium lauryl sulfate solid particles and a small amount of concentrated nitric acid into deionized water, stir and dissolve, and prepare a sodium lauryl sulfate solution with a concentration of 0.84g / L, and control the concentration of nitric acid to 0.05M;

[0031] b) Immerse a circular polyphenylene sulfide filter material with a diameter of 3.8 cm into the suspension solution in step a), and perform ultrasonic dispersion in an ultrasonic cleaner for 1 hour, so that sodium lauryl sulfate is fully adsorbed on the surface of the filter material;

[0032] c) Raise the temperature of the reaction system to 70°C, dropwise add potassium permanganate solution, the concentration of potassium permanganate is 0.05M, continue to stir and react for 1.5 h, so that the potassium permanganate and the H on the surface of the...

Embodiment 2

[0036] A kind of method that in situ generates nano flower shape manganese dioxide catalyst on filter material, comprises the following steps:

[0037] a) Add 0.024g of sodium lauryl sulfate solid particles and a small amount of concentrated nitric acid into deionized water, stir and dissolve, and prepare a sodium lauryl sulfate solution with a concentration of 0.48g / L, and control the concentration of nitric acid to 0.1M;

[0038] b) Immerse a circular polyphenylene sulfide filter material with a diameter of 3.8 cm into the suspension solution in step a), and perform ultrasonic dispersion in an ultrasonic cleaner for 1 hour, so that sodium lauryl sulfate is fully adsorbed on the surface of the filter material;

[0039] c) Raise the temperature of the reaction system to 80°C, dropwise add potassium permanganate solution, the concentration of potassium permanganate is 0.1M, continue to stir and react for 2 hours, so that the potassium permanganate and the H on the surface of the...

Embodiment 3

[0043] A kind of method that in situ generates nano flower shape manganese dioxide catalyst on filter material, comprises the following steps:

[0044]a) Add 0.042g of sodium lauryl sulfate solid particles and a small amount of concentrated nitric acid into deionized water, stir and dissolve, and prepare a sodium lauryl sulfate solution with a concentration of 0.84g / L, and control the concentration of nitric acid to 0.02M;

[0045] b) Immerse a circular polyphenylene sulfide filter material with a diameter of 3.8 cm into the suspension solution in step a), and perform ultrasonic dispersion in an ultrasonic cleaner for 1 hour, so that sodium lauryl sulfate is fully adsorbed on the surface of the filter material;

[0046] c) Raise the temperature of the reaction system to 65°C, add potassium permanganate solution dropwise, the concentration of potassium permanganate is 0.02M, continue to stir and react for 1.5h, so that the potassium permanganate and the H on the surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com