A core-shell structure magnetic carbon-based solid acid catalyst and its preparation method and application in lignocellulose hydrolysis and saccharification process

A carbon-based solid acid, lignocellulose technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of less application of catalytic solid reactions and poor catalytic effect, etc. The magnetic particle size is too large, the repeated use times are increased, and the catalytic activity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

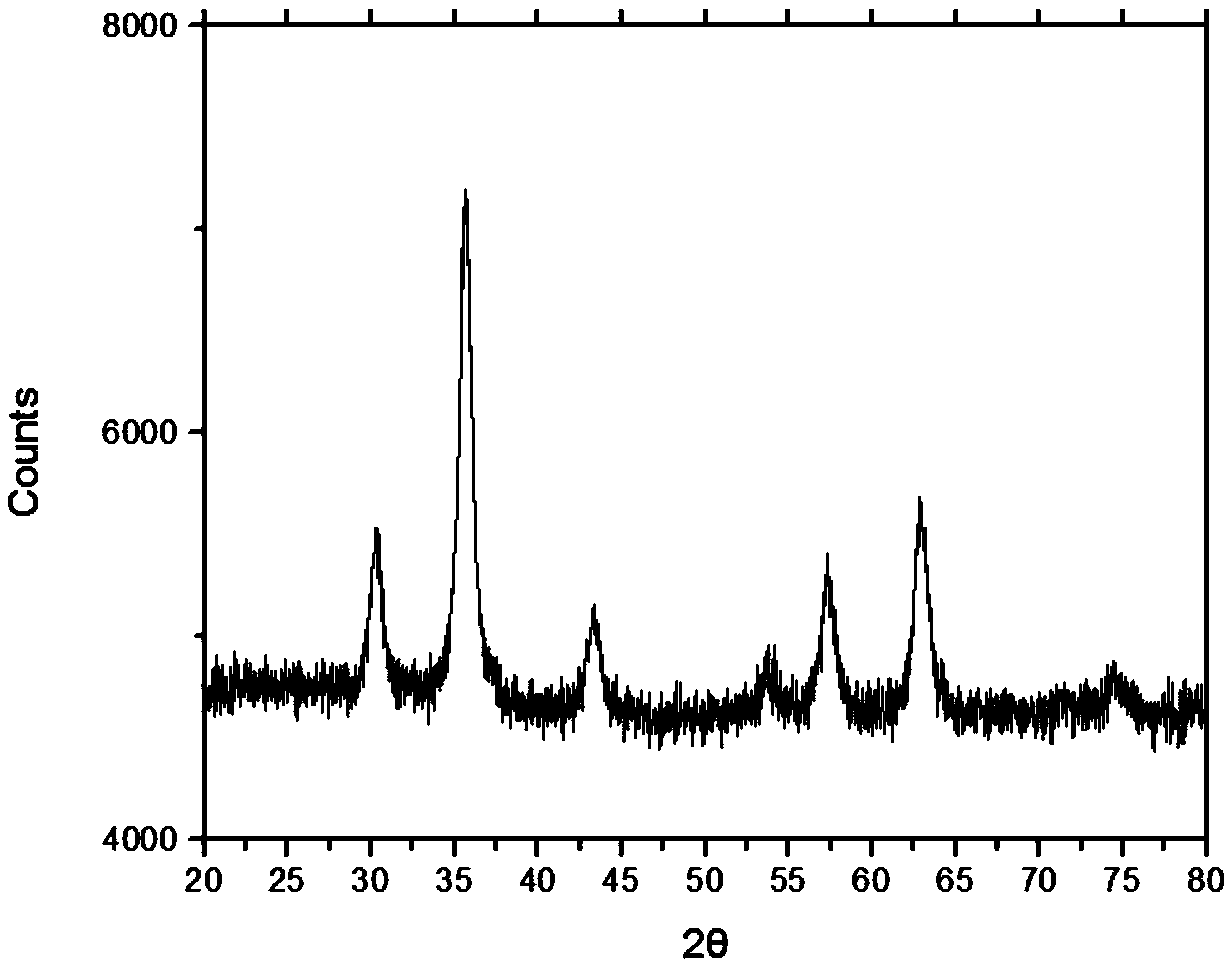

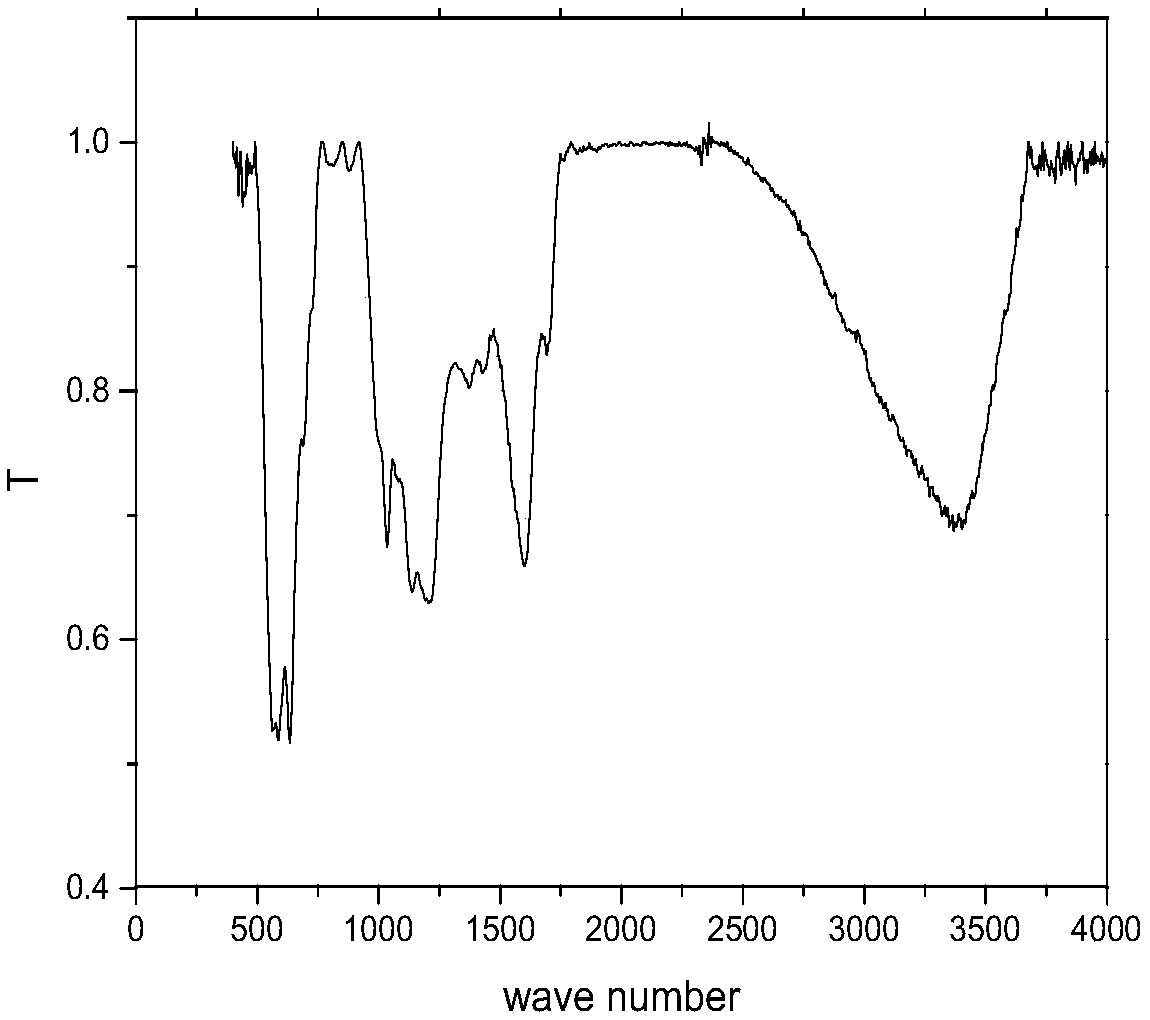

[0039] A method for preparing a magnetic carbon-based solid acid catalyst with a core-shell structure comprising the following steps:

[0040] (1) Magnetic powder Fe 3 o 4 The preparation of: Fe with a molar ratio of 1.5 to 2:1 3+ and Fe 2+ Dissolve the two salts in distilled water, mix the solution evenly, place it in a 65°C constant temperature water bath, add NaOH solution dropwise to the mixed solution while stirring rapidly, and adjust the pH value of the solution to 10-12; continue stirring and add Water ethanol, the volume ratio of described dehydrated alcohol and mixed solution is 1:5, stand still, observe black particle, be Fe 3 o 4 Magnetic particles, will contain Fe 3 o 4 Raise the mixed solution of magnetic particles to 80°C, add a buffer to adjust the pH value of the mixed solution to 4-6, add an anionic surfactant while stirring, after standing still, use an external magnet to absorb the precipitate, and the precipitate is washed and dried Magnetic powder ...

Embodiment 1

[0044] 1) Magnetic powder Fe 3 o 4 Preparation: Fe with a molar ratio of 1.5:1 3+ and Fe 2+ Dissolve the two salts in a certain amount of distilled water, mix the solution evenly, place it in a constant temperature water bath at 65°C, add NaOH solution (2mol / L) dropwise to the mixed solution while stirring rapidly, and adjust the pH of the solution to 10-12; Continue to stir and add absolute ethanol, the volume ratio of absolute ethanol to the mixed solution is 1:5, let it stand for 10 minutes, and black particles can be observed, which are magnetic particles;

[0045] Then, the temperature was raised to 80°C, and the buffering agent glacial acetic acid was added to adjust the mixed solution to pH=4-6, and the glacial acetic acid and Fe 2+ The molar ratio of 0.4:1, while stirring, add anionic surfactant oleic acid, oleic acid and Fe 2+ The molar ratio is 0.4:1. After standing for 30 minutes, use an external magnet to absorb the precipitate. The precipitate is washed with a...

Embodiment 2

[0056] Fe with a molar ratio of 2:1 3+ and Fe 2+ Dissolve the two salts in a certain amount of distilled water, mix the solution evenly, place it in a constant temperature water bath at 65°C, add NaOH solution (2mol / L) dropwise to the mixed solution while stirring rapidly, and adjust the pH of the solution to 10-12; Continue to stir and add absolute ethanol, the volume ratio of absolute ethanol to the mixed solution is 1:5, let it stand for 10 minutes, and black particles can be observed, which are magnetic particles;

[0057] Then, the temperature was raised to 80°C, and the buffering agent sodium acetate was added to adjust the mixed solution to pH = 4-6. Sodium acetate and Fe 2+The molar ratio is 0.5:1, while stirring, add the anionic surfactant sodium oleate, sodium oleate and Fe 2+ The molar ratio is 0.5:1. After standing for 30 minutes, use an external magnet to absorb the precipitate. The precipitate is washed with absolute ethanol and deionized water for many times, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com