Separation method for high oxidation rate type gold and tungsten accompanying molybdenum ores

A technology of oxidation rate and molybdenum ore, which is applied in the field of beneficiation of molybdenum ore with high oxidation rate, can solve the problems of poor stability, low cost of beneficiation agents, and large amount of beneficiation agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

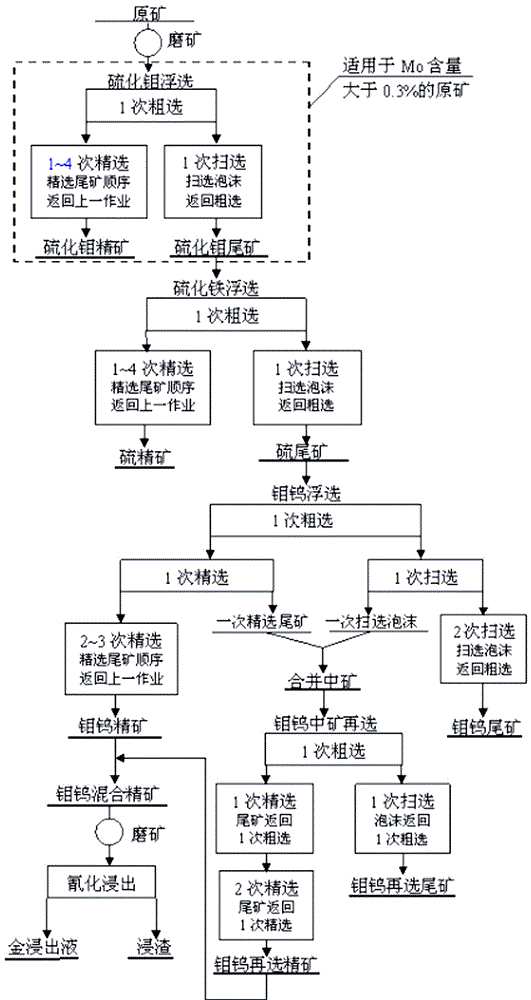

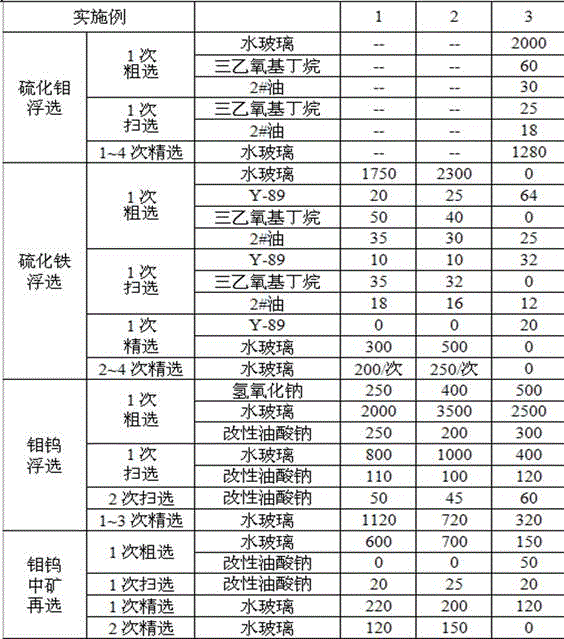

[0025] Containing 0.20% Mo, WO in raw ore 3 0.096%, Au 0.22g / t, molybdenum oxidation rate 90.43%, molybdenum sulfide content 0.018%, press figure 1 The process and the dosage of chemicals listed in Table 1 are used to obtain sulfur concentrates containing Mo18.92% and Au 235.5g / t by iron sulfide flotation, and the recovery rates are 4.94% and 53.45% respectively; molybdenum-tungsten flotation and molybdenum-tungsten medium Re-election to obtain Mo 5.37%, WO 32.87%, the recovery rates are 80.01%, 87.66% molybdenum-tungsten mixed concentrate. The cyanidation gold leaching rate of molybdenum-tungsten mixed concentrate containing Au0.89g / t and the occupancy rate of 11.75% of the original ore is 66.30%, and the recovery rate of the original ore is 7.79%. The total recoveries of molybdenum, tungsten and gold reached 84.95%, 87.66% and 61.24% respectively.

Embodiment 2

[0027] Containing Mo 0.29% and WO in raw ore 3 0.063%, Au 0.56g / t, molybdenum oxidation rate 85.71%, molybdenum sulfide content 0.042%, press figure 1 The process and the dosage of reagents listed in Table 1 were used to obtain sulfur concentrates containing 16.26% Mo and 146.0g / t Au by iron sulfide flotation, and the recovery rates of molybdenum and gold were 11.55% and 53.93% respectively; molybdenum-tungsten flotation and molybdenum-tungsten Re-election of middle ore to obtain Mo 5.07%, WO 3 1.47%, molybdenum and tungsten recovery rates are 64.64%, 84.64% molybdenum-tungsten mixed concentrate. The cyanidation gold leaching rate of the molybdenum-tungsten mixed concentrate containing 3.40g / t of Au and the occupancy rate of 22.43% of the original ore was 70.69%, and the recovery rate of the original ore was 15.86%. The total recoveries of ore molybdenum, tungsten and gold are Mo 76.19%, WO 3 84.64%, Au 69.79%.

Embodiment 3

[0029] Containing 1.01% Mo and WO in raw ore 3 0.137%, Au 2.45g / t, molybdenum oxidation rate 80.19%, molybdenum sulfide content 0.20%, press figure 1 The process and the amount of reagents listed in Table 1 are used for molybdenum sulfide flotation to obtain molybdenum sulfide concentrates containing 47.10% Mo and 470.6g / t Au, and the recovery rates of molybdenum and gold are 13.79% and 56.77% respectively; Mo 6.58%, Au 19.7g / t, molybdenum and gold recovery rates are 9.59% and 11.84% respectively; WO 3 2.89%, the recoveries of molybdenum and tungsten are Mo 72.15%, WO 3 81.29%. The cyanidation gold leaching rate of the molybdenum-tungsten mixed concentrate containing 10.1g / t of Au and the occupancy rate of 16.40% of the original ore was 70.69%, and the recovery rate of the original ore was 11.59%. The total recoveries of ore molybdenum, tungsten and gold are Mo 95.53%, WO 3 81.29%, Au 80.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com