Pearl glaze material, pearl glaze, manufacturing method of pearl glaze and pearl glaze ceramics

A technology for ceramic products and pearls, which is applied in the fields of production and processing, and research and development of ceramic glaze formulations, can solve the problems of low yield, high cost, and insufficient pattern fineness, so as to improve yield, reduce production costs, and shorten production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

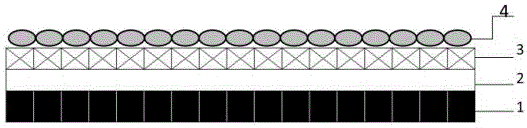

Image

Examples

preparation example Construction

[0052] A method for preparing pearl glaze is also disclosed in the embodiment of the present invention, comprising the following steps:

[0053] Step S1. Ball milling, adding water to the pearl glaze for ball milling. The pearl glaze is the glaze provided in the above examples. The weight ratio of pearl glaze to water is 1: (0.3-0.45); the ball milling time is 4-8 hours ; The fineness of the ball mill is 0-1.5% of the sieve balance of the ten-thousand-hole sieve, and the pearl glaze slurry is obtained;

[0054] Step S2. Glazing, applying the above-mentioned pearl glaze slurry to the surface of the substrate to obtain an intermediate product;

[0055] Step S3. Firing, firing the above-mentioned intermediate product at 1150-1230° C. for 80-120 min to form a pearl glaze on the surface of the substrate.

[0056] According to the present invention, step S1 is a ball milling pulping process, the flow rate of the pearl glaze slurry is preferably controlled to be 30-300s / 100ml, and t...

Embodiment 1

[0068] (a) Apply a primer to the surface of the ceramic body to form a matrix;

[0069] (b) The components are: 40 parts by weight of potassium feldspar, 15 parts by weight of Shuangfei powder, 7 parts by weight of barium carbonate, 40 parts by weight of frit, 10 parts by weight of air knife kaolin, 19 parts by weight of silicon micropowder, and 4 parts by weight of white corundum Parts, 7 parts by weight of zinc oxide, 19 parts by weight of calcined talc and pearl glaze are evenly stirred and put into a ball mill for ball milling. The ball milling method is: add water with 30% of the total mass of the glaze when throwing the ball, and the ball milling time is 4 hours. The ball milling fineness The sieve balance of the ten thousand hole sieve is 0.01%. After the ball is discharged, adjust the slurry to 100mL with a flow rate of 30s and a specific gravity of 1.30 to obtain the pearl glaze slurry. Spray the prepared glaze slurry on the surface of the dried and watered substrate ...

Embodiment 2

[0072] (a) Apply a primer to the surface of the ceramic body to form a matrix;

[0073] (b) The components are: 20 parts by weight of potassium feldspar, 5 parts by weight of Shuangfei powder, 2 parts by weight of barium carbonate, 5 parts by weight of frit, 2 parts by weight of air knife kaolin, 10 parts by weight of silicon micropowder, and 1 part by weight of white corundum 2 parts by weight of zinc oxide and 2 parts by weight of calcined talc and the pearl glaze are evenly stirred and put into a ball mill for ball milling. The ball milling method is: add water with 35% of the total mass of the glaze when throwing the ball, the ball milling time is 5 hours, and the ball milling fineness The sieve balance is 0.1%, and the slurry is adjusted to 100mL slurry with a flow rate of 300s and a specific gravity of 1.88 after the ball is discharged, and the pearl glaze slurry is obtained. Spray the prepared glaze slurry on the surface of the dried and watered substrate twice by spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com