Heat-insulating sound-insulating dry-mixed mortar

A technology of dry powder mortar, thermal insulation and sound insulation, which is applied in the field of floor dry powder mortar, which can solve the problems of not being able to meet the effect of thermal insulation and reduce the height of building floors, and achieve the effects of avoiding hollow cracks, stable performance, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

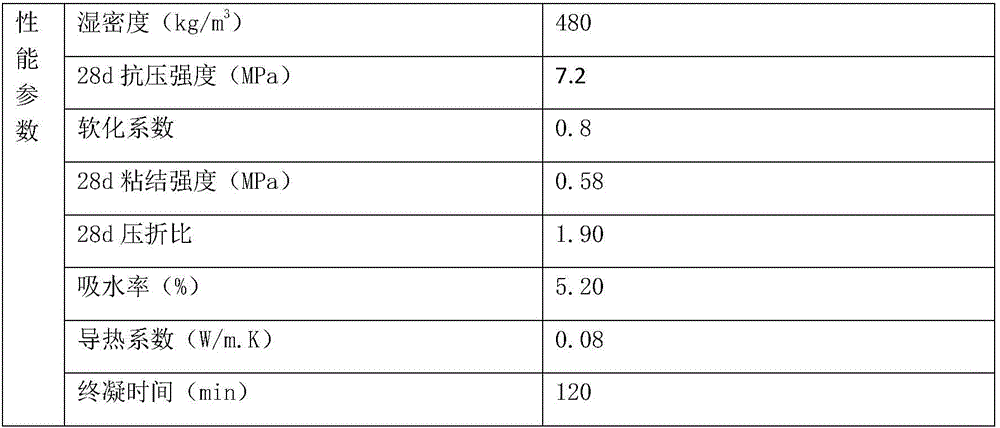

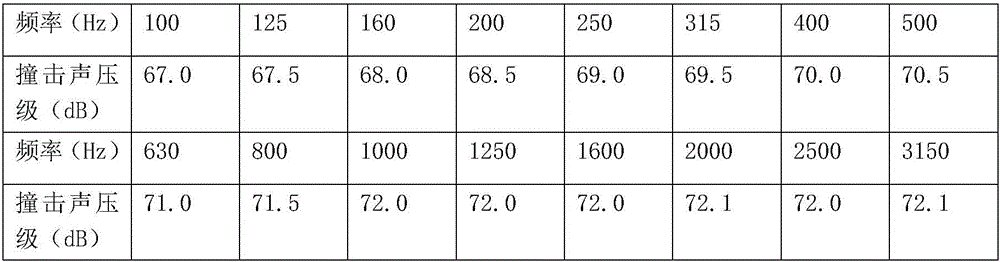

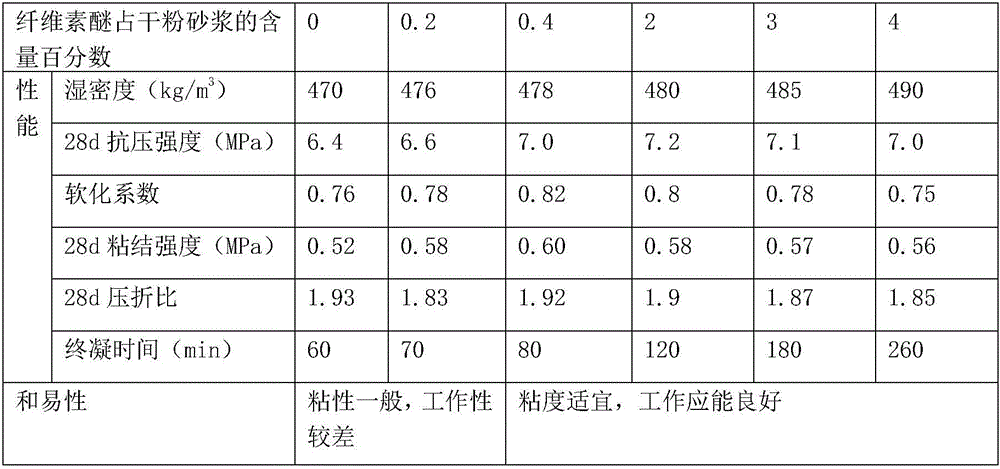

specific Embodiment 1

[0065] Cement: 30%; vitrified microbeads: 35%; elastic rubber powder: 14%; latex powder: 2%; clay: 7%; ash calcium: 5%; polypropylene fiber: 2%; cellulose ether: 3% ; Water reducing agent: 2%. The individual value evaluation of the impact sound insulation of the dry powder mortar under this formula is 53.0dB, which is 25.0dB lower than the single value evaluation (78.0dB) of the impact sound of the dry powder mortar under the basic formula. At the same time, the thermal conductivity is 0.050W / m.K, the final setting time is 280nin, and the 28d compressive strength is 7.6MPa. The dry powder mortar of this formula not only has good thermal insulation performance, but also has low thermal conductivity, high strength and good cracking performance, and has excellent building thermal insulation properties. Thermal effect, stable performance, small fluctuation, reasonable final setting time, excellent construction performance, bonding performance, non-combustibility, avoiding hollowin...

specific Embodiment 2

[0066]Cement: 40%; vitrified microbeads: 33%; elastic rubber powder: 13%; latex powder: 1.6%; clay: 6%; ash calcium: 4%; polypropylene fiber: 0.5%; cellulose ether: 0.9% ; Water reducing agent: 1%. The individual value evaluation of impact sound insulation of dry powder mortar under this formula is 55.0dB, which is 23.0dB lower than the single value evaluation (78.0dB) of dry powder mortar impact sound under the basic formula. At the same time, the thermal conductivity is 0.050W / m.K, the final setting time is 300nin, and the 28d compressive strength is 7.5MPa. The dry powder mortar of this formula not only has good thermal insulation performance, but also has low thermal conductivity, high strength and good cracking performance, and has excellent building thermal insulation properties. Thermal effect, stable performance, small fluctuation, reasonable final setting time, excellent construction performance, bonding performance, non-combustibility, avoiding hollowing and cracking...

specific Embodiment 3

[0067] Cement: 36.7%; Vitrified beads: 34%; Elastic rubber powder: 12.7%; Latex powder: 1.3%; Clay: 6%; Ash calcium: 4.5%; Polypropylene fiber: 1.3%; Cellulose ether: 2.0% ; Water reducer: 1.5%. The individual value evaluation of the impact sound insulation of the dry powder mortar under this formula is 54.0dB, which is 24.0dB lower than the single value evaluation of the impact sound of the dry powder mortar under the basic formula (78.0dB). At the same time, the thermal conductivity is 0.050W / m.K, the final setting time is 290nin, and the 28d compressive strength is 7.4MPa. The dry powder mortar of this formula not only has good thermal insulation performance, but also has low thermal conductivity, high strength and good cracking performance, and has excellent building thermal insulation properties. Thermal effect, stable performance, small fluctuation, reasonable final setting time, excellent construction performance, bonding performance, non-combustibility, avoiding hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com