Preparation method and application of composite hydrogel, composite hydrogel repair material and preparation method of composite hydrogel repair material

A technology for composite hydrogel and repair materials, which is applied in the field of composite hydrogel repair materials and their preparation, and the preparation of composite hydrogels, and can solve problems such as performance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a composite hydrogel, comprising: S1) reacting chondroitin sulfate and a first acrylate monomer in a phosphate buffer to obtain a chondroitin sulfate acrylate hydrogel monomer ; After the chondroitin sulfate acrylate hydrogel monomer is oxidized by sodium periodate, the oxidized chondroitin sulfate acrylate hydrogel monomer is obtained;

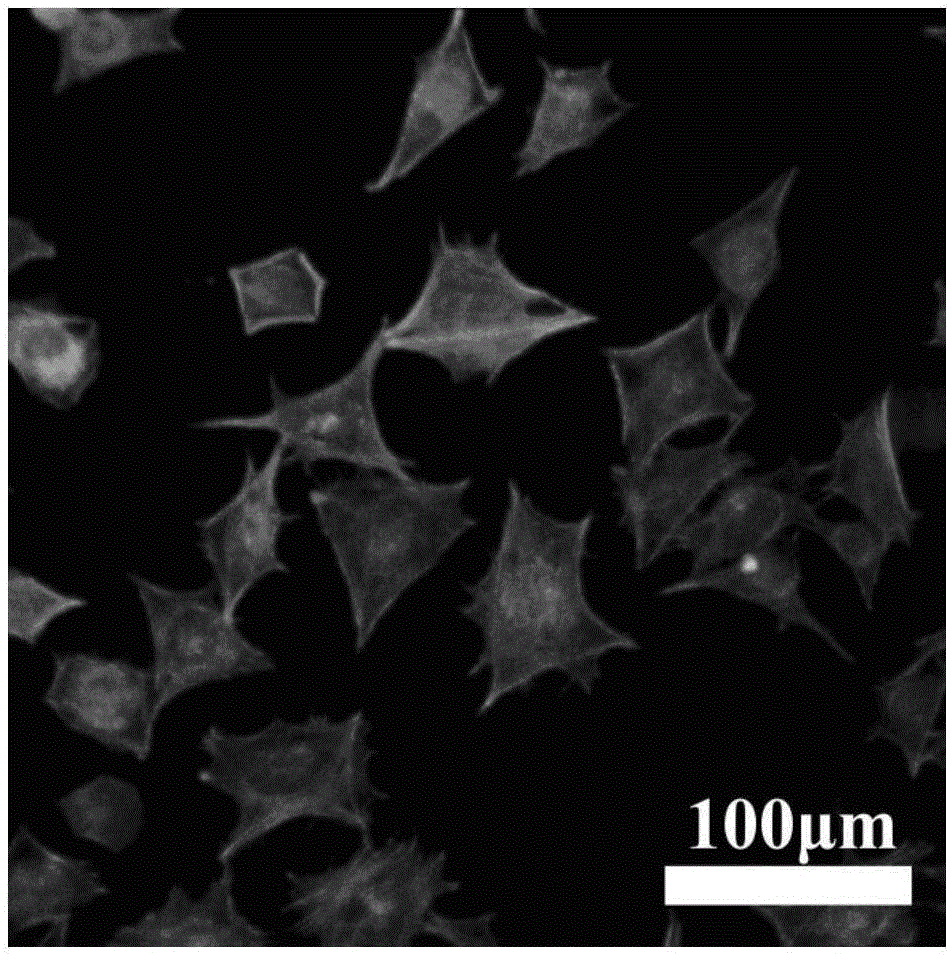

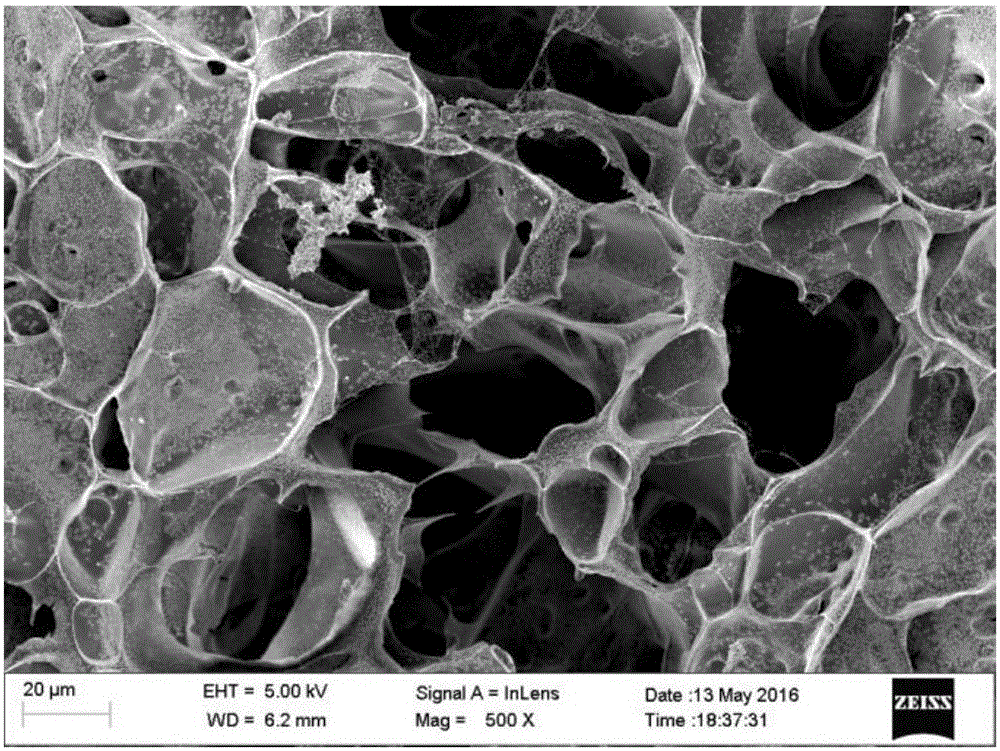

[0029] S2) Under the condition of ultraviolet light, the oxidized chondroitin sulfate acrylate hydrogel monomer and the degradable hydrogel monomer are polymerized by a photoinitiator to obtain a composite hydrogel.

[0030] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0031] Reaction of chondroitin sulfate and the first acrylate monomer in phosphate buffer; wherein, the first acrylate monomer is an acrylate monomer well known to those skilled in the art, and there is no special Restrictions, in the present inve...

Embodiment 1

[0062] Weigh 2g of chondroitin sulfate and put it into 50mL of phosphate buffered saline solution, and carry out magnetic stirring until it is completely dissolved (transparent). Use a pipette to pipette 15.0 mL of methacrylate (MA) and add it dropwise to the above solution. After adding MA dropwise for about 30 minutes, use 5M NaOH solution to adjust the solution to pH = 8.0. After the solution was placed at room temperature with magnetic stirring for 2 hours, it was placed in a refrigerator for 24 hours. Use 200mL of absolute ethanol to precipitate CS-MA, and keep stirring and mixing, wash the CS-MA precipitate with a large amount of absolute ethanol to remove unreacted MA, and then centrifuge. The sample was frozen at -80°C for 3 days to obtain the chondroitin sulfate acrylate hydrogel monomer, and the centrifuge tube was sealed with filter paper and a rubber band, and stored in a desiccator.

Embodiment 2

[0064]Weigh 5g of gelatin into 50mL of PBS solution, and carry out magnetic stirring until completely dissolved (transparent). Use a pipette gun to pipette 2.4mL of methacrylate (MA) and add it dropwise to the above solution. After the dropwise addition of MA, continue the magnetic stirring reaction in a water bath with a constant temperature of 50°C for 3h, and use 200ml of PBS at 40°C for the reaction solution to terminate the reaction, and keep stirring to mix. The above solution was put into a dialysis bag, and dialyzed in pure water at 40° C. for 6 days with constant stirring. The dialyzed solution was centrifuged and frozen at -80°C for 3 days to obtain a gelatin acrylate hydrogel monomer (GelMA hydrogel monomer), which was stored in a desiccator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com