Reflective material for protecting electric power facilities and preparation method of reflective material

A technology of reflective materials and power facilities, which is applied in the field of polymer materials, can solve the problems of decreased reflective effect, short service life, easy wear and tear, etc., and achieves the effects of good reflective effect, not easy to yellow, and good reflective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

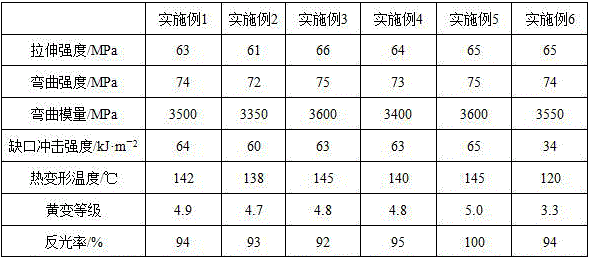

Examples

Embodiment 1

[0021] A reflective material for the protection of electric power facilities. The raw materials include, in parts by weight, 5 parts of polybutylene adipate, 0.5 parts of trimethylolpropane, 0.4 parts of 1,6-hexamethylene diisocyanate, and 0.1 parts of silicon carbide powder. 0.2 parts, 0.2 parts of tetraethyl silicate, 0.1 parts of lecithin, 1 part of polystyrene, 2 parts of polyamide resin, 0.8 parts of EPDM rubber, 0.1 parts of glyoxal, 0.2 parts of nano titanium dioxide, 0.3 parts of compatibilizer 0.1 part, 0.1 part of terpineol, 0.1 part of antioxidant, 0.1 part of cellulose, 0.4 part of coconut acid diethanolamide.

[0022] Among them, the compatibilizer is a mixture of ABS~g~MAH and PE~g~MAH in a weight ratio of 1:1; the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:3; Cellulose is methyl cellulose.

[0023] The preparation method of the above-mentioned light-reflecting material for protecting electric facilities comprises the...

Embodiment 2

[0030] A reflective material for the protection of electric power facilities. The raw materials include, in parts by weight, 7 parts of polybutylene adipate, 0.7 parts of trimethylolpropane, 0.5 parts of 1,6-hexamethylene diisocyanate, and 0.3 parts of silicon carbide powder. 0.4 parts of tetraethyl orthosilicate, 0.3 parts of lecithin, 2 parts of polystyrene, 4 parts of polyamide resin, 1.3 parts of EPDM rubber, 0.3 parts of glyoxal, 0.4 parts of nano titanium dioxide, 0.5 parts of compatibilizer part, 0.2 part of terpineol, 0.4 part of antioxidant, 0.3 part of cellulose, and 0.7 part of coconut acid diethanolamide.

[0031] Among them, the compatibilizer is a mixture of ABS~g~MAH and PE~g~MAH in a weight ratio of 1:1; the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:3; Cellulose is methyl cellulose.

[0032] The preparation method of the above-mentioned light-reflecting material for protecting electric facilities comprises the foll...

Embodiment 3

[0039] A reflective material for the protection of electric power facilities. The raw materials include, in parts by weight, 8 parts of polybutylene adipate, 0.8 parts of trimethylolpropane, 0.6 parts of 1,6-hexamethylene diisocyanate, and 0.4 parts of silicon carbide powder. 0.3 parts, 0.3 parts of tetraethyl orthosilicate, 0.2 parts of lecithin, 3 parts of polystyrene, 6 parts of polyamide resin, 1.8 parts of EPDM rubber, 0.6 parts of glyoxal, 0.5 parts of nano titanium dioxide, 0.4 parts of compatibilizer part, 0.2 part of terpineol, 0.3 part of antioxidant, 0.4 part of cellulose, and 0.8 part of coconut acid diethanolamide.

[0040] Among them, the compatibilizer is a mixture of ABS~g~MAH and PE~g~MAH in a weight ratio of 1:1; the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 in a weight ratio of 1:3; Cellulose is methyl cellulose.

[0041] The preparation method of the above-mentioned light-reflecting material for protecting electric facilities compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com