Single-shell multi-layer mixed spherical storage tank and manufacturing technology thereof

A technology for spherical storage tanks and manufacturing processes, applied in the field of single-shell multi-layer hybrid spherical storage tanks and their manufacturing processes, can solve the problems of medium leakage and release, thin wall thickness, poisoning, etc., achieve extended service life, and simple processing , to ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific implementation plan

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the drawings and specific embodiments.

[0035] A manufacturing process of a single-shell multi-layer hybrid spherical storage tank is as follows:

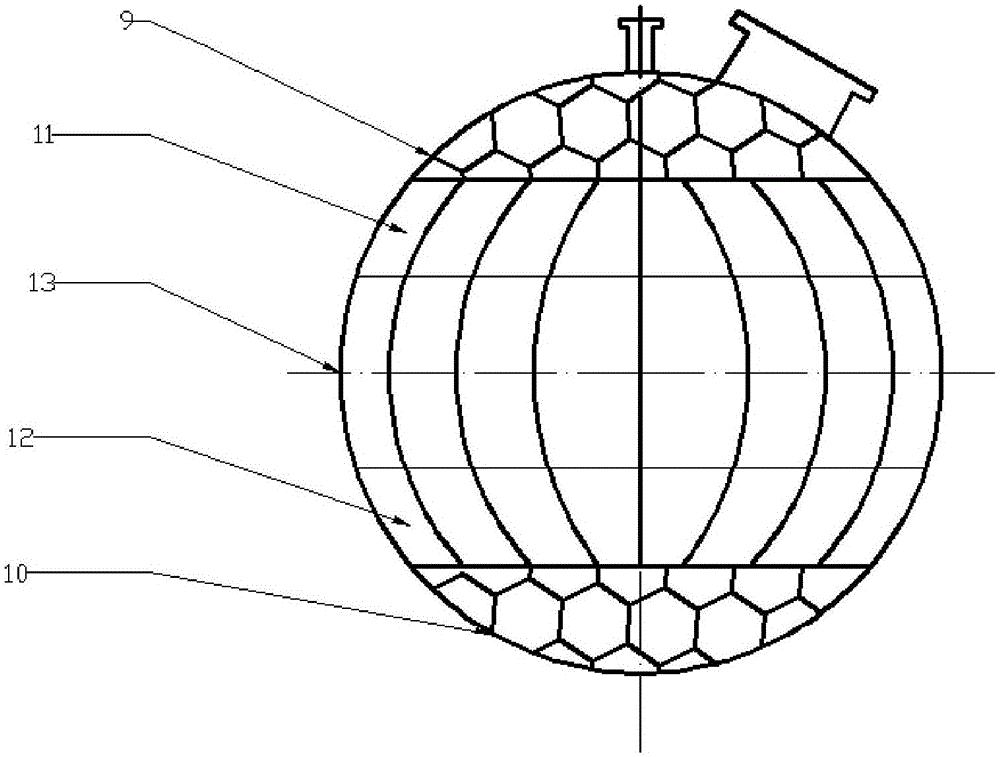

[0036] First, see figure 1 with 6 , The steel plate is welded into a hybrid shell 1 by welding technology. The hybrid shell 1 includes the equatorial zone 13, the temperate zone and the polar plate. Among them, the equatorial zone and the temperate zone adopt the orange petal type, and the polar plate adopts the football petal type; the temperate zone includes Upper temperate zone 11 and lower temperate zone 12; the pole plate includes an upper plate 9 and a lower pole plate 10. A manhole 7 and a material inlet and outlet 8 are reserved by welding on the top of the hybrid shell.

[0037] Second, see Figure 7 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com