Oxygen reduction catalyst for fuel cell cathode and preparation method of ordered electrode thereof

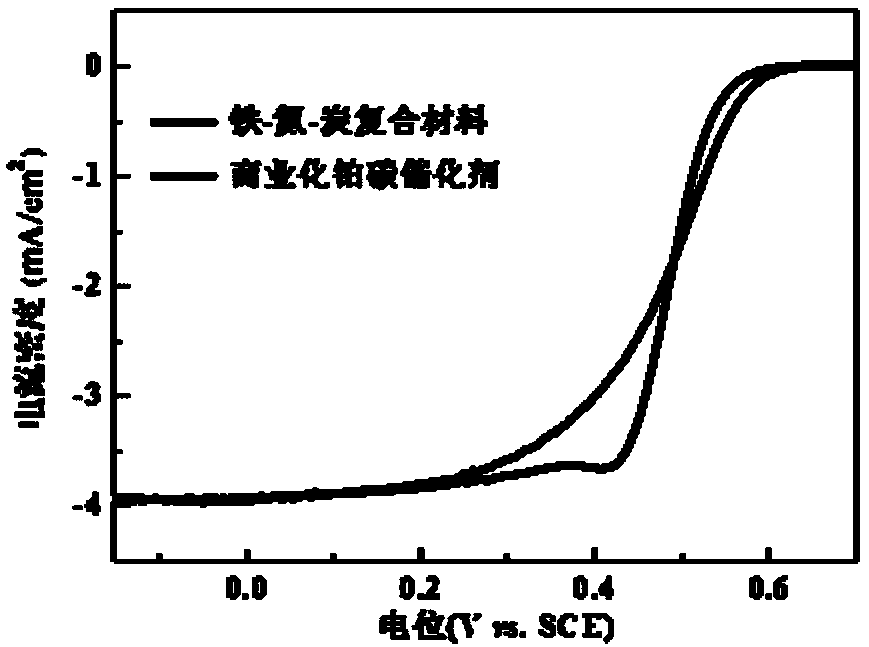

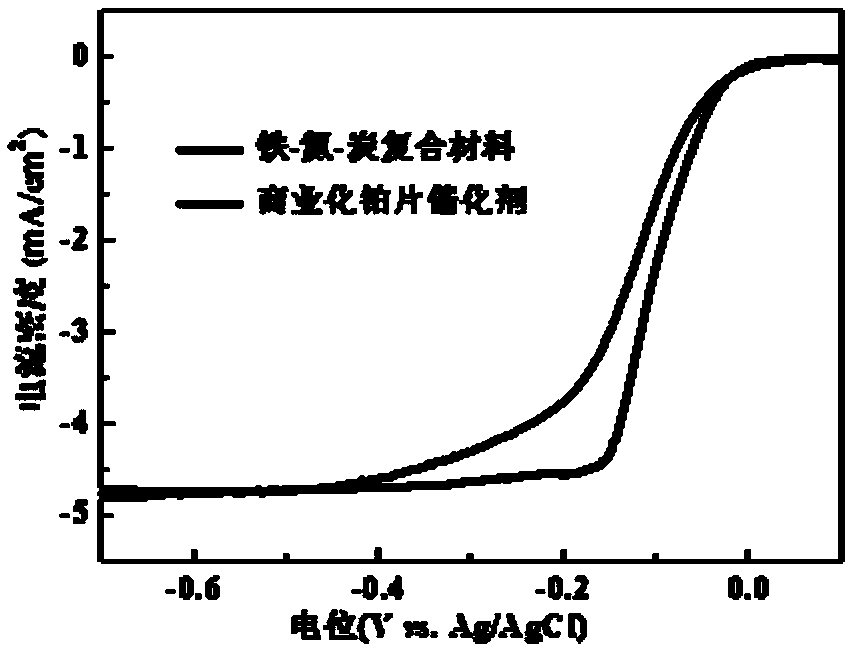

A fuel cell cathode and catalyst technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of short life, high cost of noble metal catalysts, etc., and achieve the effect of large specific surface area and smooth gas-liquid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

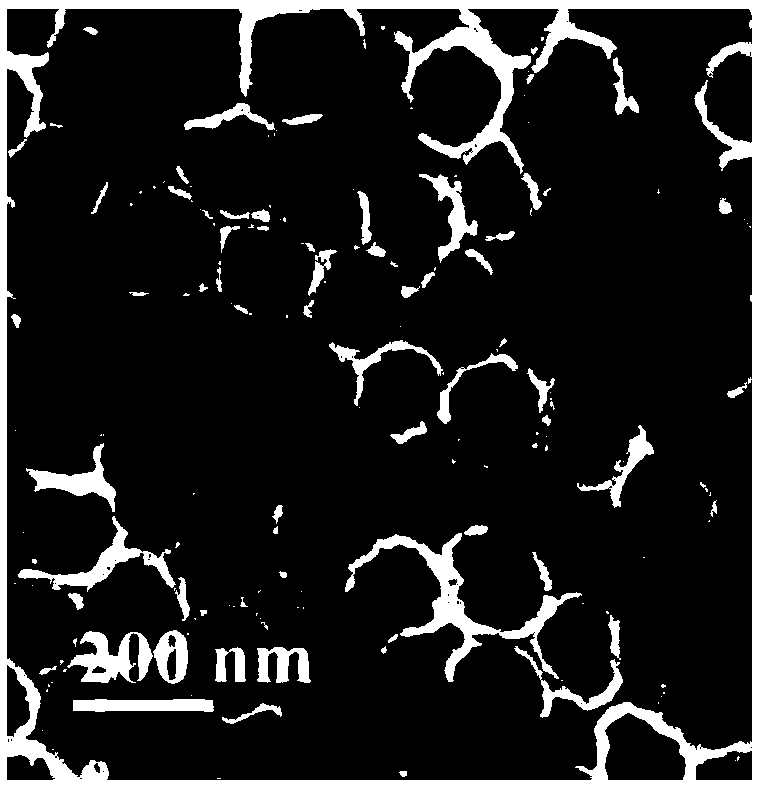

[0040] Dissolve 5.0 g of sucrose in 20 ml of water, add 5.0 g of silica microspheres with a particle size of about 150 nm under stirring, continue stirring for 40 minutes, filter with suction, and dry under vacuum at 80°C for 12 hours to obtain a white cohesive solid. Take 2.0 g of the white solid in a ceramic ark, place it in a high-temperature tube furnace, and under the protection of Ar, raise the temperature to 900 °C for 1 hour at 5 °C / min to obtain a black powder, which is carbon-coated silica microspheres. The black powder was treated with 3M NaOH at 80° C. for 24 hours, then suction-filtered, washed with water, and vacuum-dried at 80° C. to obtain hollow carbon spheres.

[0041] Get 40mg of hollow carbon spheres and disperse them in 80ml of pH=8 tromethamine (tris) buffer solution, add 160mg of dopamine and 216mg of FeCl 3 ·6H 2 O, stirred for 6 hours, suction filtered, washed with water, vacuum dried at 80°C, placed in a high-temperature tube furnace, and under the p...

Embodiment 2

[0044] Add 10.0 g of sucrose into 50 ml of water and stir vigorously to dissolve it. Add 5.0 g of silica microspheres with a particle diameter of about 500 nm, continue stirring for 40 minutes, centrifuge, and vacuum dry at 70° C. for 12 hours to obtain a white cohesive solid. Get 2.0g of this white solid in high temperature tube furnace, under N 2 Under protection, the temperature was raised to 900° C. at 3° C. / min, and kept for 2 hours to obtain carbon-coated silica microspheres. The product was added with 10wt.% hydrofluoric acid, stirred overnight, filtered with suction, washed with hot water, and dried in vacuum at 80°C to obtain three-dimensionally interconnected hollow carbon spheres.

[0045] Get 100mg hollow carbon spheres and disperse them in 80ml pH=8 tromethamine (tris) buffer solution, add 160mg dopamine and 216mg FeCl 3 ·6H 2 O, stirred for 6 hours, filtered with suction, washed with water, and dried under vacuum at 60°C for later use. The dried product was p...

Embodiment 3

[0047] Add 5.0g of silica microspheres with a particle size of about 500nm into the 20ml phenolic resin reaction solution prepared in advance, stir overnight, transfer to a hydrothermal kettle, heat at 130°C for 6 hours, centrifuge, and vacuum dry at 70°C for 12 hours. A brown product was obtained. Get 2.0g of this product in the high temperature tube furnace, under N 2 Under protection, the temperature was raised to 1000° C. at 5° C. / min and kept for 5 hours to obtain carbon-coated silica microspheres. Grind the product into a fine powder, add 10wt.% hydrofluoric acid, stir overnight, filter with suction, wash with hot water, and dry in vacuum at 80°C to obtain hollow carbon spheres.

[0048] Take 200 mg of hollow carbon spheres and 50 mg of iron phthalocyanine, mix them evenly with a ball mill, transfer them to a ceramic ark, place them in a high-temperature tube furnace, and raise the temperature to 800 °C at 5 °C / min for 5 hours under the protection of Ar to obtain the O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com