A nerve guide with contact guiding function and its preparation method and device

A nerve conduit and orifice technology, used in rayon manufacturing, hollow filament manufacturing, textiles and papermaking, etc., can solve the problem of not being able to fully simulate the real microenvironment of nerves, and avoid additional procedures and structures such as secondary processing. Uniform and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

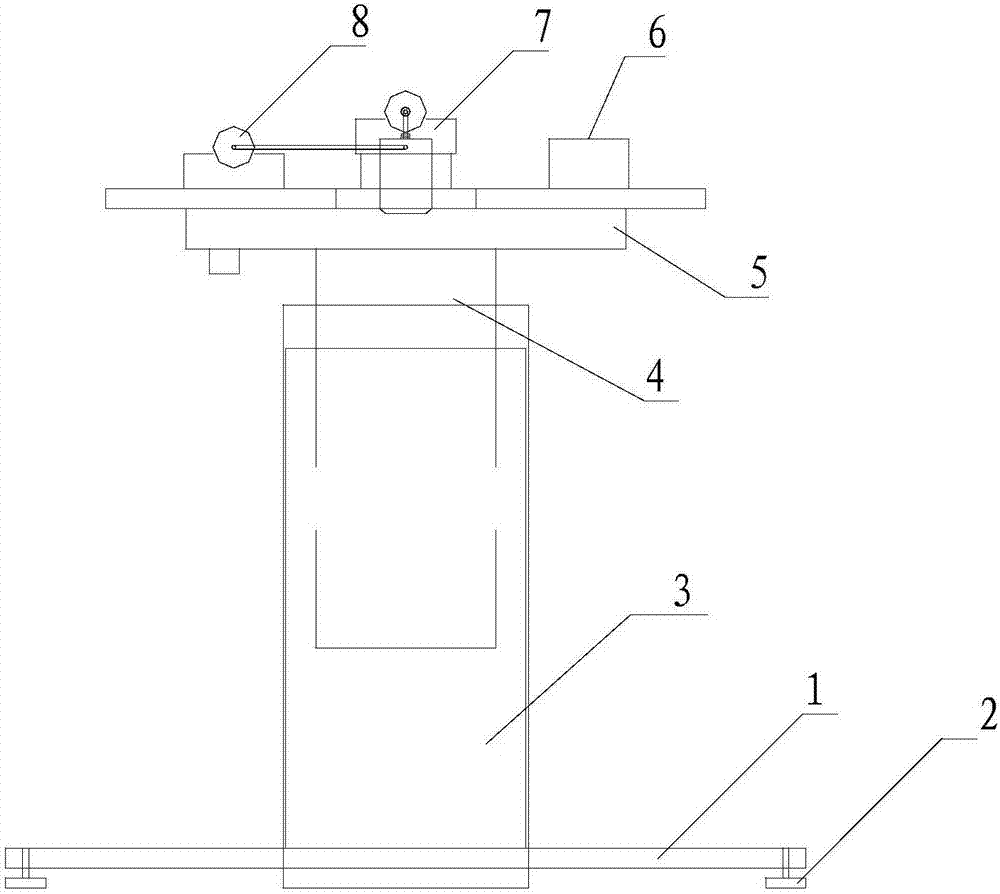

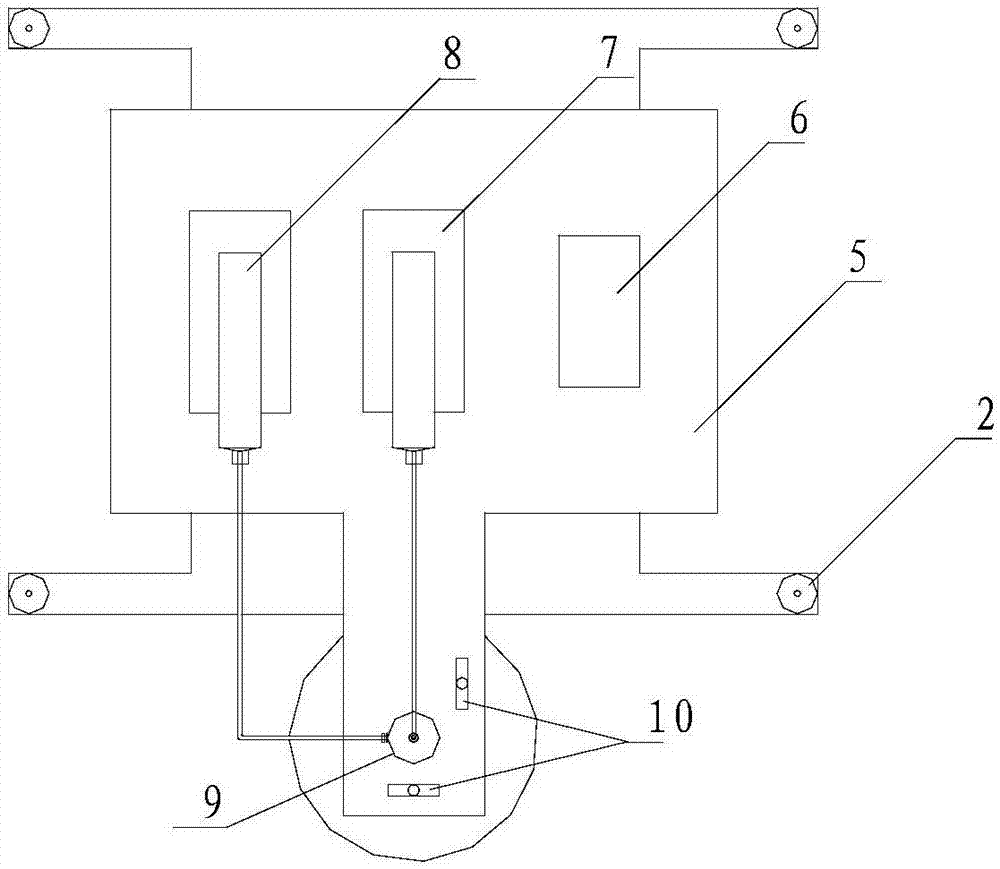

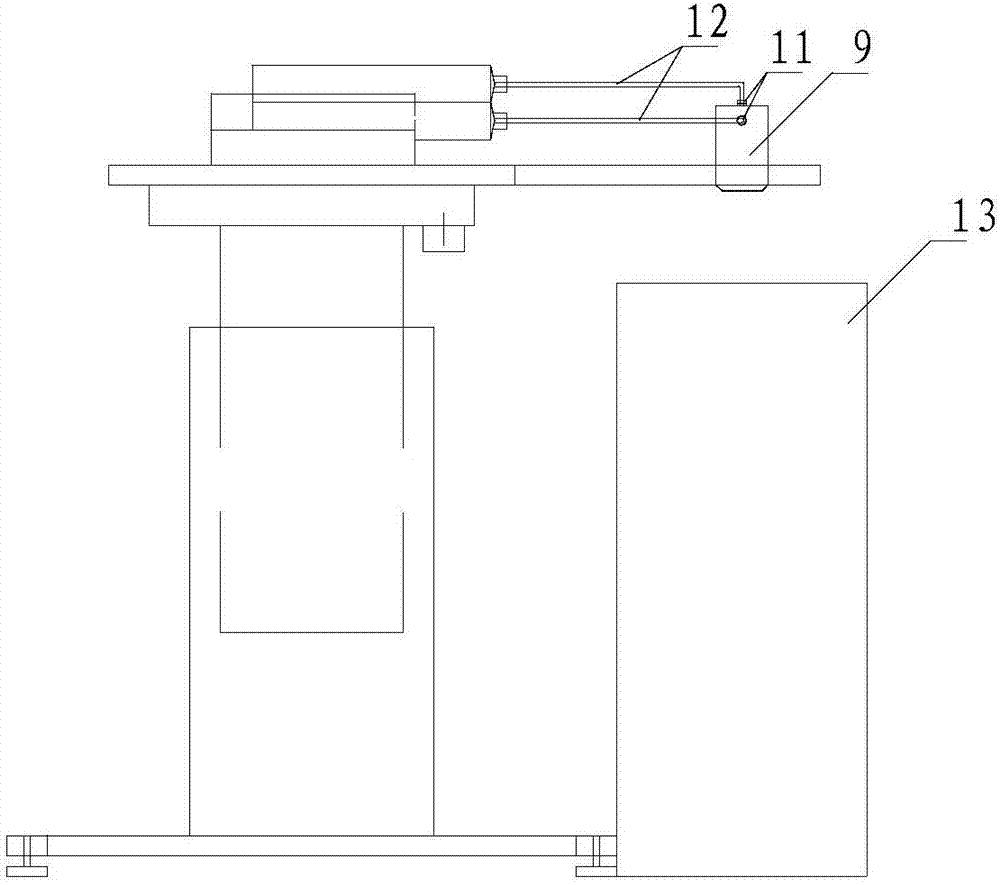

[0082] Embodiment 1, preparation polyacrylonitrile nerve guide

[0083] In this embodiment, the polymer material is polyacrylonitrile (PAN), the solvent material is dimethyl sulfoxide (DMSO), and the non-solvent and coagulant material are deionized water. Polyacrylonitrile is dissolved in dimethyl sulfoxide to form a polymer solution with a concentration of 6-10w / w%. The polymer solution was stirred at room temperature for 8 hours so that the polymer could be uniformly dissolved, left to stand for 12 hours to remove air bubbles in the solution, and then dried and sealed for storage. Put the polyacrylonitrile solution and deionized water into two injection needles respectively, and under the control of the micro-syringe pump, the flow rate control range of the polymer solution and deionized water is 0.5–3ml / min. Spinnerets with smooth outer walls and inner holes and spinnerets with 12 and 16 grooves in the inner holes were used for preparation respectively, and the air gap hei...

Embodiment 2

[0084] Embodiment 2, preparation polylactic acid-glycolic acid copolymer nerve guide

[0085] In this example, the polymer material is polylactic acid-glycolic acid copolymer (PLGA), the solvent material is dimethyl sulfoxide (DMSO), and the non-solvent and coagulant material are deionized water. The polylactic acid-glycolic acid copolymer is dissolved in dimethyl sulfoxide to form a polymer solution with a concentration of 15-25w / w%. Polylactic acid-glycolic acid copolymer dissolves slowly under block conditions, and an ultrasonic cleaner can be used to vibrate for a short time to speed up the dissolution rate. The polymer solution was stirred at room temperature for 8 hours so that the polymer could be uniformly dissolved, left to stand for 12 hours to remove air bubbles, and then dried and sealed for storage. Put the polylactic acid-glycolic acid copolymer solution and deionized water into two injection needles respectively, and under the control of the micro-syringe pump, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com