Environment-friendly plastic material

A plastic material and environmental protection technology, which is applied in the field of plastic material preparation technology and environmental protection, can solve the problems of high preparation cost, poor flame retardancy and mechanical properties, etc., and achieve the effects of low preparation cost, good flame retardancy effect and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

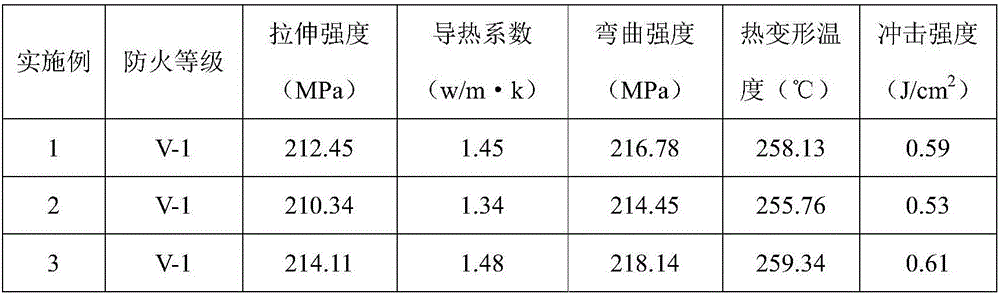

Examples

preparation example Construction

[0061] The preparation method of the environment-friendly plastic material comprises the following steps:

[0062] S1: preparing an additive, the preparation method of the additive comprises the following steps:

[0063] S11: Mix the generator, coupling agent, compatibilizer, and antioxidant and heat up to 120-135°C, react at a rotation speed of 200-300r / min for 40-60min, and obtain material A;

[0064] S12: Add regulator, strengthening agent and coagulant to the material A prepared in step S11, mix and heat up to 150-160°C, react at a rotation speed of 300-400r / min for 150-180min, and obtain material B;

[0065] S13: Add a plasticizer, a stabilizer, and a terminator to the material B prepared in step S12, mix and cool down to 110-120° C., react at a rotation speed of 200-300 r / min for 60-90 minutes, and prepare an additive;

[0066] S2: The addition agent prepared in step S1, nylon, maleic anhydride-styrene-propylene copolymer, 2-hydroxy-4-octyloxybenzobutanone, butenyl biss...

Embodiment 1

[0070] An environment-friendly plastic material, in parts by weight, comprising the following raw materials: 85 parts of nylon, 60 parts of maleic anhydride-styrene-propylene copolymer, 50 parts of 2-hydroxy-4-octyloxybenzobutanone, butyl 30 parts of alkenyl bis stearamide, 22 parts of polybutylene terephthalate, 18 parts of polyether glycerol, 15 parts of brominated paraffin, 12 parts of olive oil, 12 parts of AR glass fiber, carboxyethyl fiber 9 parts of prime, 20 parts of filler, 10 parts of additive, 5 parts of flame retardant, 4 parts of smoke suppressant, 2 parts of ultraviolet absorber, 2 parts of tackifier, 1.5 parts of softener;

[0071] Described filler is nano calcium carbonate;

[0072] The addition agent is in parts by weight, including the following raw materials: 0.8 parts of generating agent, 1.4 parts of coupling agent, 1 part of compatibilizer, 0.8 parts of antioxidant, 0.9 parts of regulator, 0.8 parts of strengthening agent, coagulant 1.4 parts, 1.5 parts ...

Embodiment 2

[0096] An environment-friendly plastic material, in parts by weight, comprising the following raw materials: 50 parts of nylon, 42 parts of maleic anhydride-styrene-propylene copolymer, 35 parts of 2-hydroxy-4-octyloxybenzobutanone, butyl 20 parts of alkenyl bis stearamide, 15 parts of polybutylene terephthalate, 12 parts of polyether glycerol, 10 parts of brominated paraffin, 10 parts of olive oil, 8 parts of AR glass fiber, carboxyethyl fiber 6 parts of plain, 15 parts of filler, 8 parts of additive, 4 parts of flame retardant, 3 parts of smoke suppressant, 1 part of ultraviolet absorber, 1 part of tackifier, 1 part of softener;

[0097] Described filler is nano calcium carbonate;

[0098] The addition agent is in parts by weight, including the following raw materials: 0.6 parts of generating agent, 1.2 parts of coupling agent, 0.8 parts of compatibilizer, 0.6 parts of antioxidant, 0.6 parts of regulator, 0.6 parts of strengthening agent, coagulant 1.2 parts, 1.2 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com