Anti-pollution-flashover insulator

An insulator and anti-pollution flashover technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc., can solve problems that affect the safe operation of power systems, easily cause major accidents, and increase leakage current. Achieve the effects of reducing the probability of pollution flashover, firm and reliable bonding performance, strong hiding power and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the anti-pollution flashover insulator provided in this example is as follows:

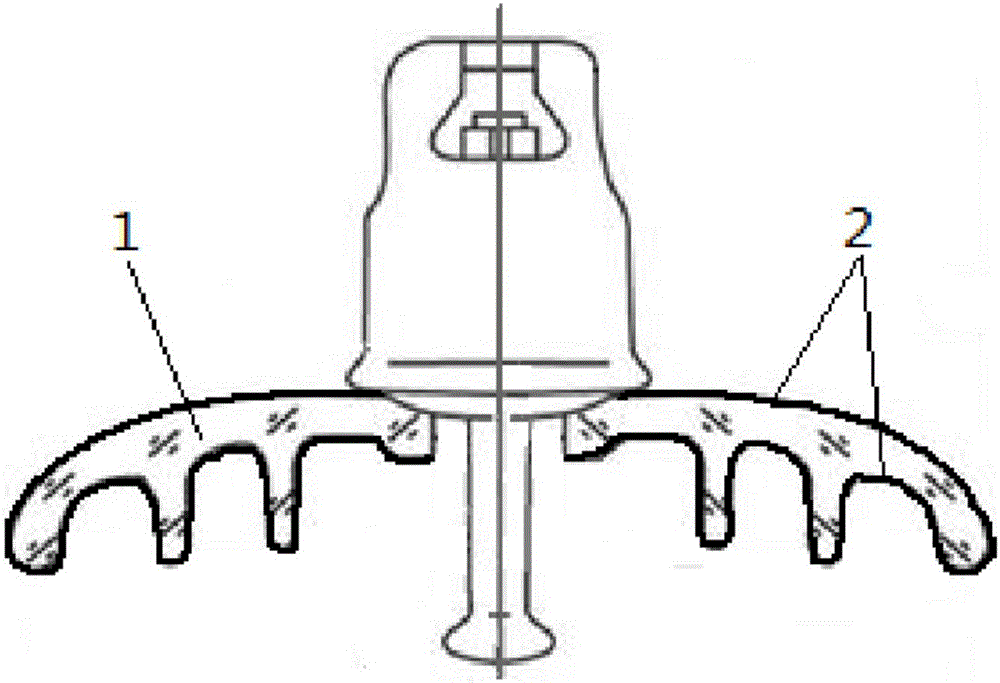

[0026] 1) Preparation of coating: Add 5% nano-silica, 5% dicumyl peroxide and 8% ferrocene into 82% fluorocarbon coating and stir evenly to form nano-fluorocarbon Coat 2 of paint.

[0027] 2) Preparation of the anti-fouling flashover insulator: uniformly coat the paint prepared in 1) on the inner and outer surfaces of the insulator main body 1, and wait until the paint is completely dry to form the coating 2, and the preparation is completed.

Embodiment 2

[0029] The preparation method of the anti-pollution flashover insulator provided in this example is as follows:

[0030] 1) Preparation of coating: Add 10% nano silicon dioxide, 10% benzoyl peroxide and 14% dialkylcopper lithium into 66% fluorocarbon coating and stir evenly to form nano fluorine Carbon Coat 2 paint.

[0031] 2) Preparation of the anti-fouling flashover insulator: uniformly coat the paint prepared in 1) on the inner and outer surfaces of the insulator main body 1, and wait until the paint is completely dry to form the coating 2, and the preparation is completed.

Embodiment 3

[0033] The preparation method of the anti-pollution flashover insulator provided in this example is as follows:

[0034] 1) Preparation of the coating: the crosslinking agent (2,5-dimethyl-2,5 di-tert-butyl peroxide hexane and 2,5- Dimethyl-2,5 di-tert-butylperoxyhexane 50% each) and 11% organometallic compounds (30% diphenylchrome, 20% sodium ethoxide and 50% ferric citrate) add 74% Stir evenly in the fluorocarbon coating to form nano-fluorocarbon coating 2 coating.

[0035] 2) Preparation of the anti-fouling flashover insulator: uniformly coat the paint prepared in 1) on the inner and outer surfaces of the insulator main body 1, and wait until the paint is completely dry to form the coating 2, and the preparation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com