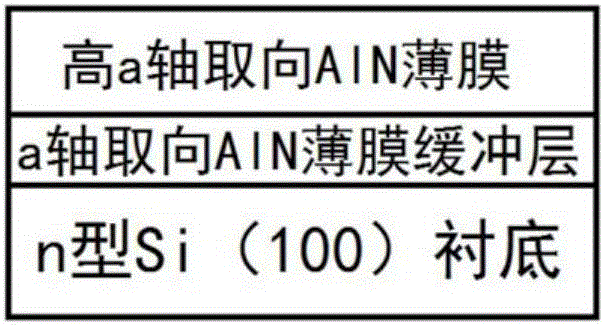

A-axis oriented reinforced type AlN film and preparation method thereof

An enhanced and oriented technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as broken fingers, easy conduction, and frequency restriction of surface acoustic wave devices, achieving high yield, Strong reliability, the effect of strong product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

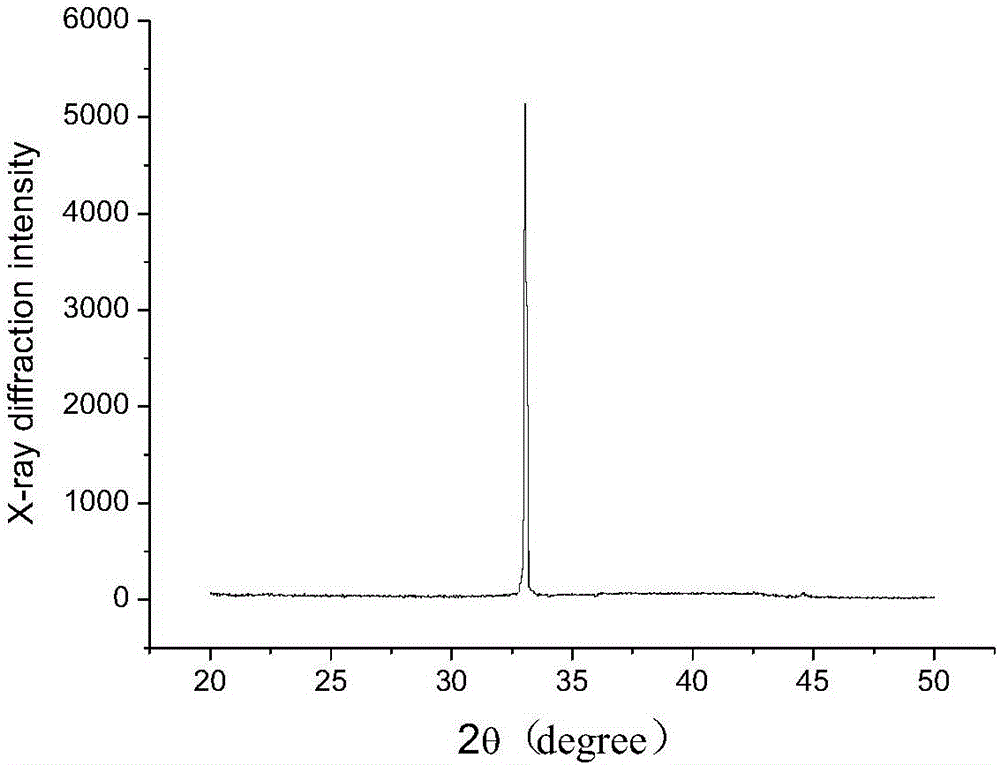

Embodiment 1

[0034] A method for preparing a-axis orientation enhanced AlN film includes the following steps:

[0035] Before step A, the surface of the n-type Si (100) substrate is usually polished and cleaned;

[0036] Surface polishing treatment: polishing the surface of the n-type Si (100) substrate with diamond slurry. After observing the surface of the substrate without scratches with an optical microscope, the substrate is polished by the prior art chemical mechanical polishing method.

[0037] Cleaning treatment: First, put the n-type Si(100) substrate in acetone and ultrasonically treat it for about 10 minutes, clean it with deionized water, put it in ethanol for ultrasonic treatment for about 10 minutes, clean it with deionized water, and put it in. Ultrasonic treatment in ionized water for about 10 minutes, and finally blow dry with pure nitrogen.

[0038] Step A: Put the n-type Si (100) substrate into the chamber of the magnetron sputtering system for vacuum argon treatment;

[0039] Pu...

Embodiment 2

[0049] A method for preparing a-axis orientation enhanced AlN film includes the following steps:

[0050] Before step A, the surface of the n-type Si (100) substrate is usually polished and cleaned;

[0051] Surface polishing treatment: polishing the surface of the n-type Si (100) substrate with diamond slurry. After observing the surface of the substrate without scratches with an optical microscope, the substrate is polished by the prior art chemical mechanical polishing method.

[0052] Cleaning treatment: First, put the n-type Si(100) substrate in acetone and ultrasonically treat it for about 10 minutes, clean it with deionized water, put it in ethanol for ultrasonic treatment for about 10 minutes, clean it with deionized water, and put it in. Ultrasonic treatment in ionized water for about 10 minutes, and finally blow dry with pure nitrogen.

[0053] Step A: Put the n-type Si (100) substrate into the chamber of the magnetron sputtering system for vacuum argon treatment;

[0054] Pu...

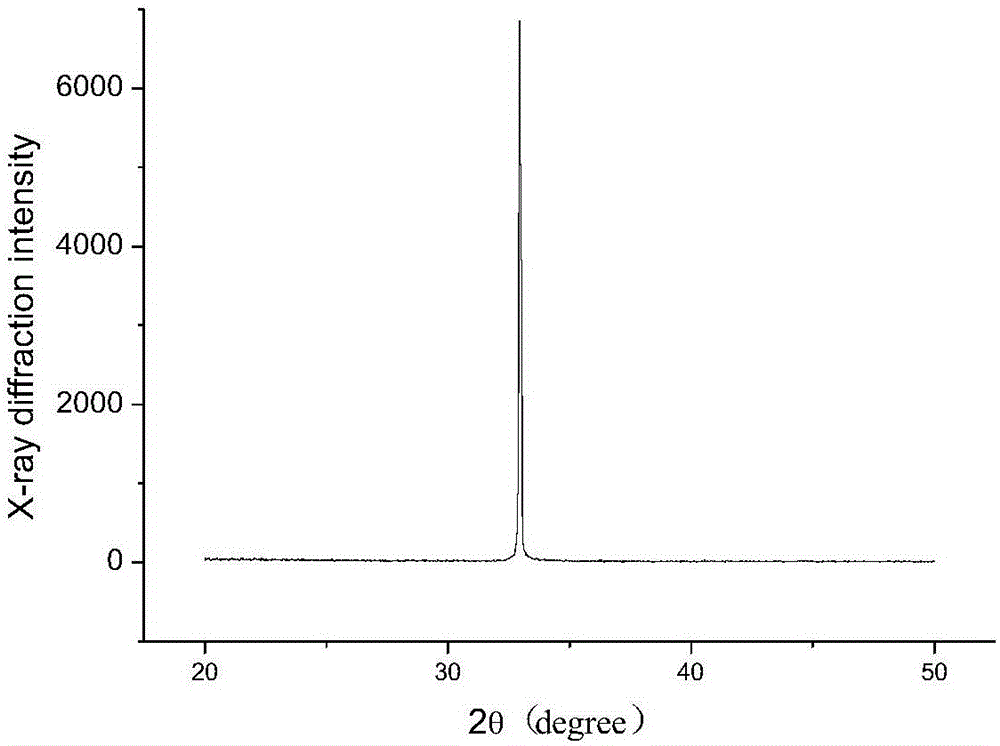

Embodiment 3

[0064] A method for preparing a-axis orientation enhanced AlN film includes the following steps:

[0065] Before step A, the surface of the n-type Si (100) substrate is usually polished and cleaned;

[0066] Surface polishing treatment: polishing the surface of the n-type Si (100) substrate with diamond slurry. After observing the surface of the substrate without scratches with an optical microscope, the substrate is polished by the prior art chemical mechanical polishing method.

[0067] Cleaning treatment: First, put the n-type Si(100) substrate in acetone and ultrasonically treat it for about 10 minutes, clean it with deionized water, put it in ethanol for ultrasonic treatment for about 10 minutes, clean it with deionized water, and put it in. Ultrasonic treatment in ionized water for about 10 minutes, and finally blow dry with pure nitrogen.

[0068] Step A: Put the n-type Si (100) substrate into the chamber of the magnetron sputtering system for vacuum argon treatment;

[0069] Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com