Nanometer luminescent fiber and preparation method thereof

A light-emitting fiber and nanotechnology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of difficult dispersion of quantum dots and high packaging requirements, and achieve the effect of reducing packaging requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

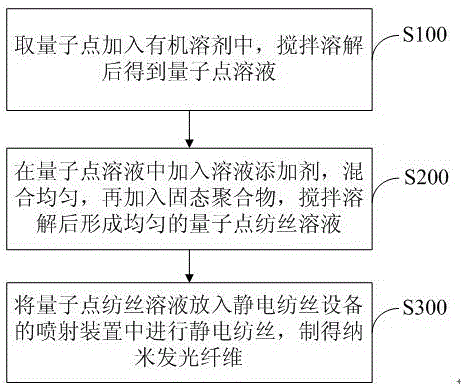

Method used

Image

Examples

Embodiment 1

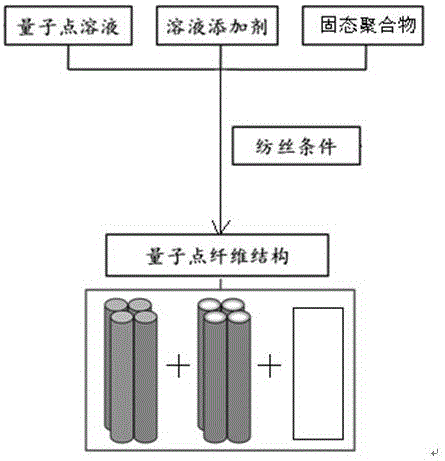

[0040] Preparation of Zn X Cd 1-X Se / ZnS quantum dot solid nanofiber, the steps are as follows:

[0041] (1) Preparation of quantum dot spinning solution: Zn prepared by hot injection method X Cd 1-X Se / ZnS quantum dot mixture, the Zn X Cd 1-X The Se / ZnS quantum dot mixture was washed and dried under vacuum at 60 °C to obtain solid quantum dots. Take 60 mg of the powdered quantum dot solid and add 7.5 mL of CHCl 3 , stirred for 30 min, dissolved to obtain a uniform quantum dot solution. Then add 2.5 mL tetrahydrofuran (THF) solution additive to the quantum dot solution, mix well, then add 3.75 g polymethyl methacrylate (PMMA) solid polymer, stir magnetically at room temperature for 3 h, dissolve evenly, and obtain a solution with a certain viscosity. and conductive quantum dot spinning solution.

[0042] (2) Preparation of quantum dot solid nanofibers: Put the quantum dot spinning solution obtained in step (1) into the spraying device of the electrospinning equipment f...

Embodiment 2

[0044] Preparation of Zn X Cd 1-X Se / ZnS quantum dot tubular nanofibers, the steps are as follows:

[0045] (1) Preparation of quantum dot spinning solution: Zn prepared by hot injection method X Cd 1-X Se / ZnS quantum dot reaction solution, the Zn X Cd 1-X The Se / ZnS quantum dot reaction solution was washed and dried under vacuum at 60° C. to obtain a quantum dot solid. Add 120 mg of this quantum dot solid in powder form to 7.5 mL of CHCl 3 , stirred for 30 minutes, and dissolved to obtain a uniform quantum dot solution. Add 2.5mL THF solution additive to the quantum dot solution, mix evenly, then add 3.25g PMMA solid polymer, stir magnetically at room temperature for 3h, dissolve evenly, and obtain a quantum dot spinning solution with a certain viscosity and conductivity.

[0046] (2) Preparation of quantum dot tubular nanofibers: Put the quantum dot spinning solution obtained in step (1) into the spraying device of the electrospinning equipment for spinning, use the d...

Embodiment 3

[0048] Preparation of Zn X CD 1-X Se / ZnS quantum dot ribbon nanofibers, the steps are as follows:

[0049] (1) Preparation of quantum dot spinning solution: Zn prepared by hot injection method X CD 1-X Se / ZnS quantum dot reaction solution, the Zn X CD 1-X The Se / ZnS quantum dot reaction solution was washed and dried under vacuum at 60° C. to obtain a quantum dot solid. Add 150 mg of powdered quantum dot solid to 7.5 mL of CHCl 3 , stirred for 30 min, and dissolved to obtain a uniform quantum dot solution. Add 2.5mL THF solution additive to the quantum dot solution, mix evenly, then add 3g PMMA solid polymer, stir magnetically at room temperature for 3h, dissolve evenly, and obtain a quantum dot spinning solution with a certain viscosity and conductivity.

[0050] (2) Preparation of quantum dot ribbon nanofibers: Put the quantum dot spinning solution obtained in step (1) into the spraying device of the electrospinning equipment for spinning, and use the drum-type aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com