Film bulk acoustic resonator harmonic tuned amplifier module

A technology of thin-film bulk acoustic wave and amplification module, which is applied in the fields of microelectronics, communication and semiconductor, and can solve the problems of mutual interference, long distance of transistors and high loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

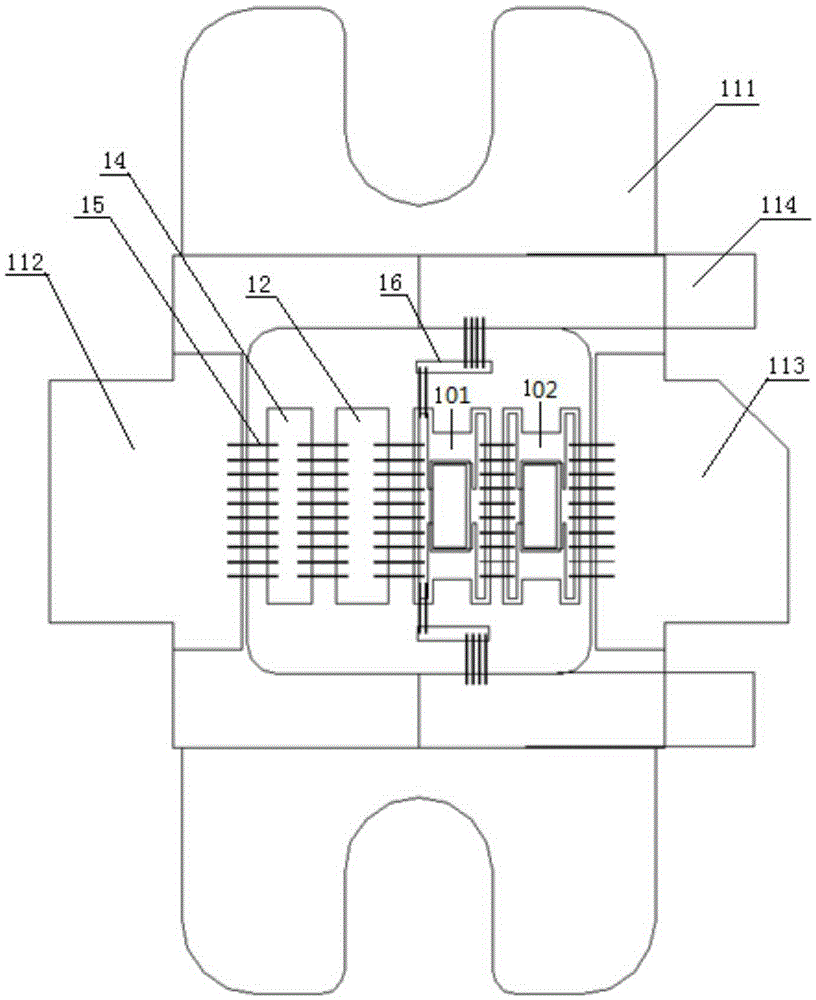

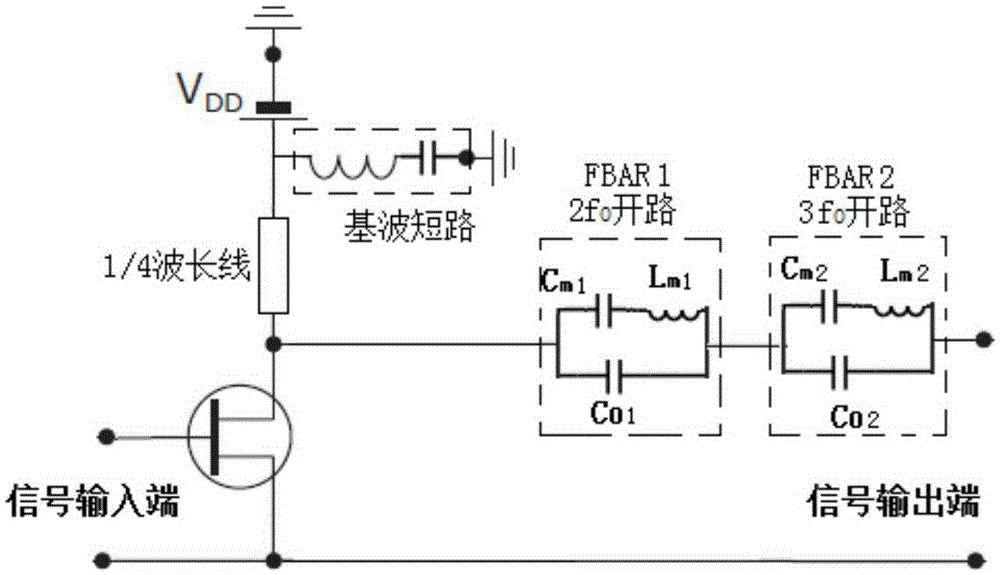

[0044] The top view of the thin film bulk acoustic resonator harmonic tuning amplifying module provided by Embodiment 1 of the present invention is as follows: figure 1 shown. The amplifying module includes a transistor 12 , thin film bulk acoustic resonators 101 and 102 , a shell base 111 , a bonding wire 15 , a 1 / 4 wavelength microstrip line 16 and an internal matching capacitor 14 .

[0045] The transistors may be gallium nitride high electron mobility transistors, gallium arsenide high electron mobility transistors, metal oxide field effect transistors, lateral metal oxide field effect transistors, or junction transistors. The input terminal, the output terminal and the ground terminal of the transistor are respectively the gate, the drain and the source of the transistor or the base, the collector and the emitter of the transistor. In this embodiment, a gallium nitride high electron mobility transistor is used as an example for illustration.

[0046] like figure 1 and ...

Embodiment 2

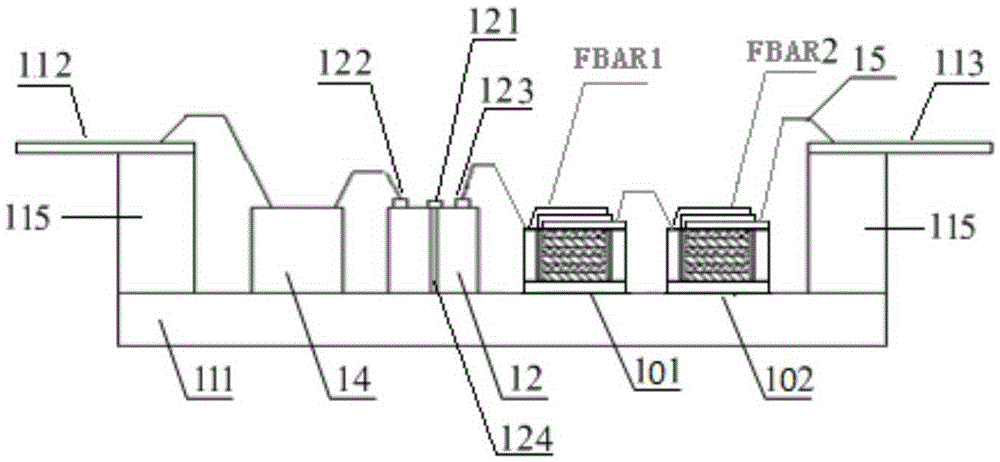

[0063] The cross-sectional view of the input film bulk acoustic resonator harmonic tuning amplification module provided in Embodiment 2 is as follows: Figure 10 As shown, the equivalent circuit diagram is shown in Figure 11 shown.

Embodiment 3

[0066] The top view of the input-output thin-film bulk acoustic resonator harmonic tuning amplifier module provided in Embodiment 3 is as follows: Figure 12 As shown, the equivalent circuit diagram is shown in Figure 13 shown. The difference from Embodiment 1 or Embodiment 2 is that the transistor input terminal and output terminal perform harmonic tuning on the transistor at the same time. In this embodiment, both the input end of the transistor and the output end of the transistor are provided with an array of thin film bulk acoustic resonator groups, each array of thin film bulk acoustic resonator groups includes two thin film bulk acoustic resonator groups, and each group has a thin film bulk acoustic resonator group .

[0067] The thin film bulk acoustic resonator harmonic tuning amplification module provided in the third embodiment encapsulates the thin film bulk acoustic resonator group and the transistor on the same base to realize the open circuit of the second ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Characteristic impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com