Sunscreen moisturizing lotion and preparing method and application thereof

A technology of carboxymethyl chitosan and nano-titanium dioxide, applied in the field of sunscreen moisturizing milk and its preparation, to achieve the effect of protecting fibroblasts, scavenging free radicals, and overcoming agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

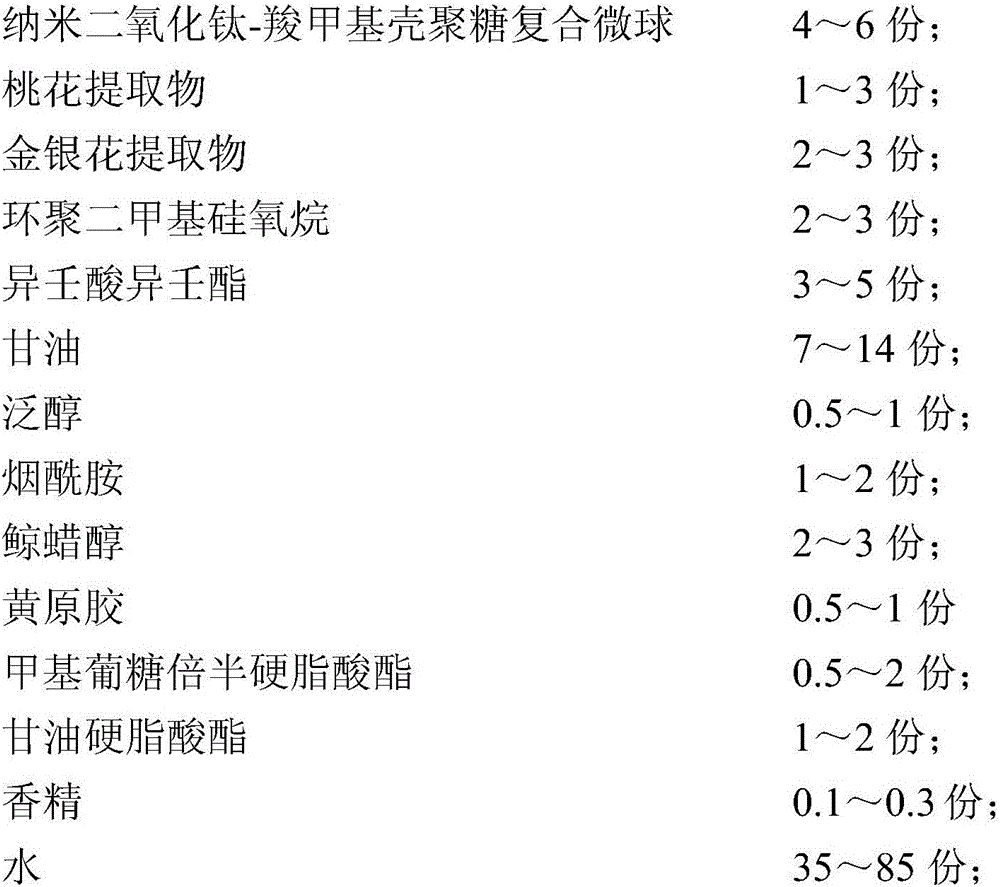

[0051] A sunscreen moisturizer, comprising the following components by parts by mass:

[0052]

[0053] The preparation method of described sunscreen moisturizing lotion comprises the following steps:

[0054] (1) The viscosity average molecular weight is 6×10 4 Chitosan and absolute ethanol were mixed according to the mass volume ratio (g:ml) of 1:30, ultrasonically treated for 15 minutes, then added with a mass fraction of 40% sodium hydroxide solution, and alkalized at 4°C for 4.5 hours; Then slowly add chloroacetic acid, stir and react at 65°C for 5h to obtain carboxymethyl chitosan with a degree of substitution of 1.45; wherein, the mass ratio of chitosan to sodium hydroxide in the sodium hydroxide solution is 1:5; The mass ratio of polysaccharide to chloroacetic acid is 1:4;

[0055](2) the carboxymethyl chitosan that step (1) is made is dissolved in water, and the carboxymethyl chitosan solution that obtains mass fraction is 15%, is that the nano titanium dioxide o...

Embodiment 2

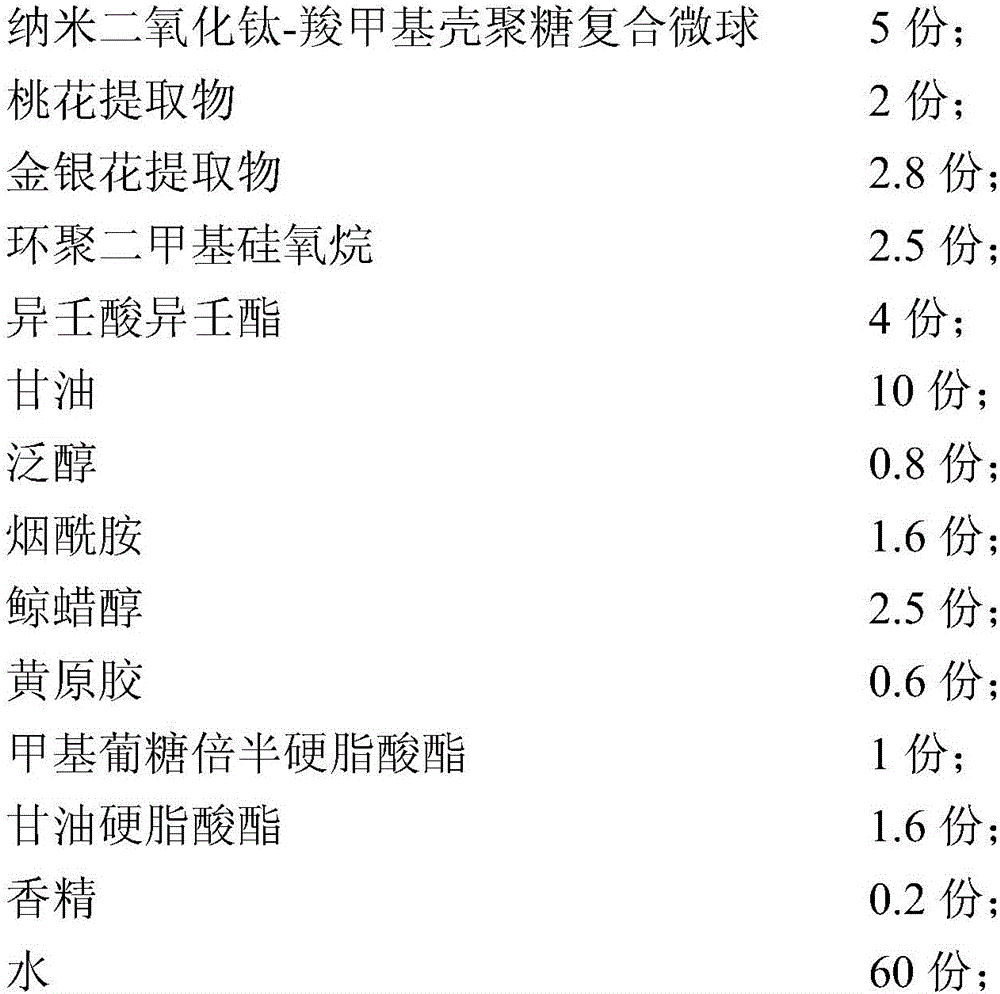

[0061] A sunscreen moisturizer, comprising the following components by parts by mass:

[0062]

[0063] The preparation method of described sunscreen moisturizing lotion comprises the following steps:

[0064] (1) Set the viscosity-average molecular weight to 0.8×10 4 Chitosan and absolute ethanol were mixed according to the mass volume ratio (g:ml) of 1:25, ultrasonically treated for 20min, then added with a mass fraction of 45% sodium hydroxide solution, and alkalized at 10°C for 4h; then Slowly add chloroacetic acid, stir and react at 60°C for 6 hours to obtain carboxymethyl chitosan with a degree of substitution of 1.26; wherein, the mass ratio of chitosan to sodium hydroxide in sodium hydroxide solution is 1:4; chitosan The mass ratio of sugar to chloroacetic acid is 1:3;

[0065] (2) the carboxymethyl chitosan that step (1) is made is dissolved in water, and the carboxymethyl chitosan solution that obtains mass fraction is 10%, is that the nanometer titanium dioxide...

Embodiment 3

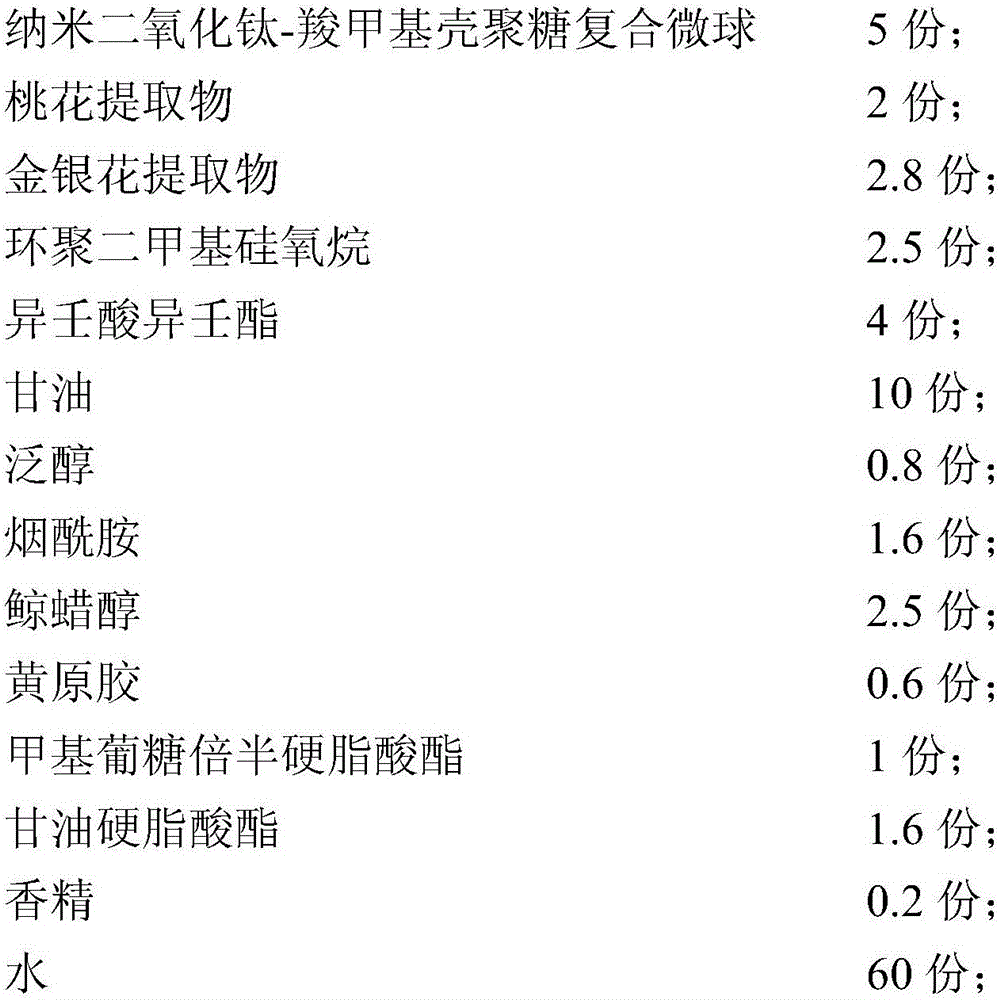

[0071] A sunscreen moisturizer, comprising the following components by parts by mass:

[0072]

[0073]

[0074] The preparation method of described sunscreen moisturizing lotion comprises the following steps:

[0075] (1) The viscosity average molecular weight is 16×10 4 Chitosan and absolute ethanol were mixed according to the mass volume ratio (g:ml) of 1:50, ultrasonically treated for 10min, then added with a mass fraction of 45% sodium hydroxide solution, and alkalized at 0°C for 5h; then Slowly add chloroacetic acid, stir and react at 70°C for 3 hours to obtain carboxymethyl chitosan with a degree of substitution of 1.36; wherein, the mass ratio of chitosan to sodium hydroxide in sodium hydroxide solution is 1:6; chitosan The mass ratio of sugar to chloroacetic acid is 1:5;

[0076] (2) the carboxymethyl chitosan that step (1) is made is dissolved in water, obtains the carboxymethyl chitosan solution that mass fraction is 20%, is that the nanometer titanium dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com