Magnetic nanoscale oil absorption material as well as preparation method and application thereof

An oil-absorbing material and magnetic nanotechnology, applied in the field of materials, can solve the problems of low oil-water selectivity, harsh synthesis conditions, and unknown ecotoxicity, and achieve the effect of simple and easy preparation method, simple preparation method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment discloses a method for preparing a magnetic nano-oil-absorbing material applied in the fields of environmental governance, oil and gas fields, etc., including the following steps:

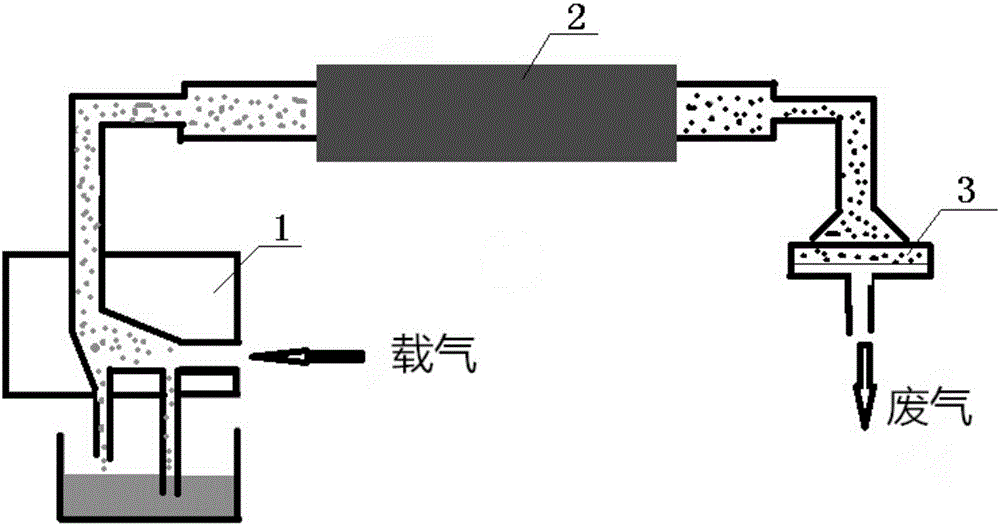

[0037] Dissolve 6g of sucrose and 5g of ferrous sulfate in 50ml of water, place figure 1 In the middle aerosol sprayer 1, the carrier gas (nitrogen) is introduced to form a spray, which enters the tube furnace 2 to be heated and reacted. The reaction temperature is 1000 degrees Celsius, and the reaction time at each reaction temperature is 4s to 10s. The spray time depends on The amount of the raw material in the aerosol sprayer, and finally the magnetic nano oil-absorbing material is collected on the filter membrane of the filter 3.

[0038] Characterization and functional identification of the magnetic nano-oil-absorbing material prepared in this example:

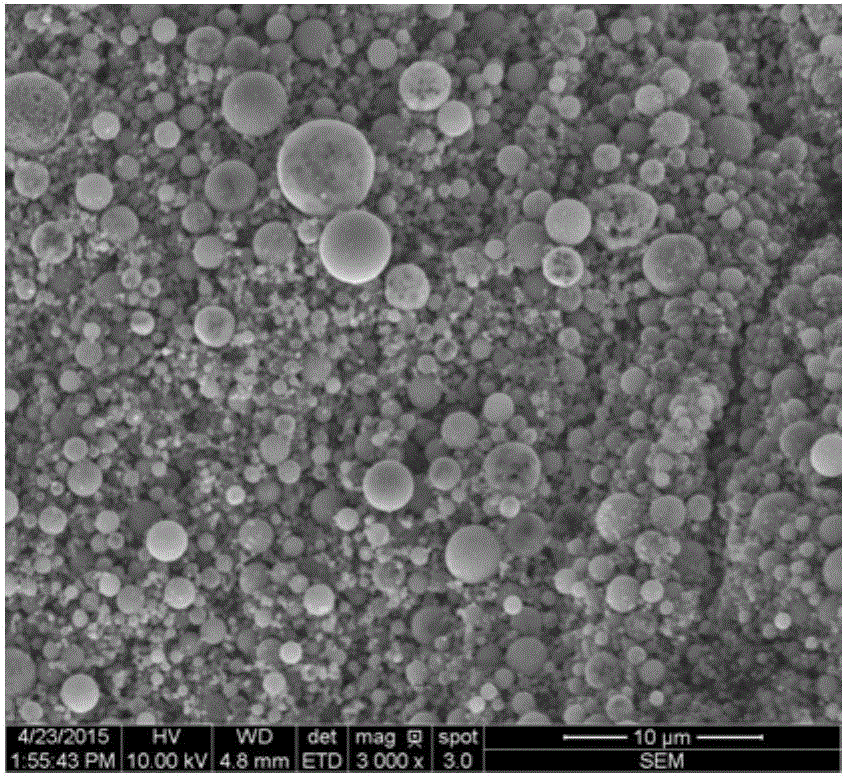

[0039] The magnetic nano-oil-absorbing material prepared in this example was scanned and magnified by an electron mic...

Embodiment 2

[0043] This embodiment discloses a method for preparing a magnetic nano oil-absorbing material, comprising the following steps:

[0044] 1) Mix the raw materials according to the following weight ratio:

[0045]

[0046] 2) Put the mixed solution in an aerosol sprayer, spray small droplets driven by an inert gas carrier gas, enter a tube furnace for heating and react, the temperature of the tube furnace is 600-900 degrees Celsius, and the reaction time is 4s~10s.

[0047] 3) Filtrating the material obtained from the reaction in step 2) through a membrane filter to obtain the magnetic nano oil-absorbing material.

[0048] The water-soluble sugar is glucose; the water-soluble iron salt is ferric nitrate; and the carrier gas is nitrogen.

[0049] The use of the magnetic nano-oil-absorbing material prepared in this example in oil-water separation, treatment of oily sewage, or water purification.

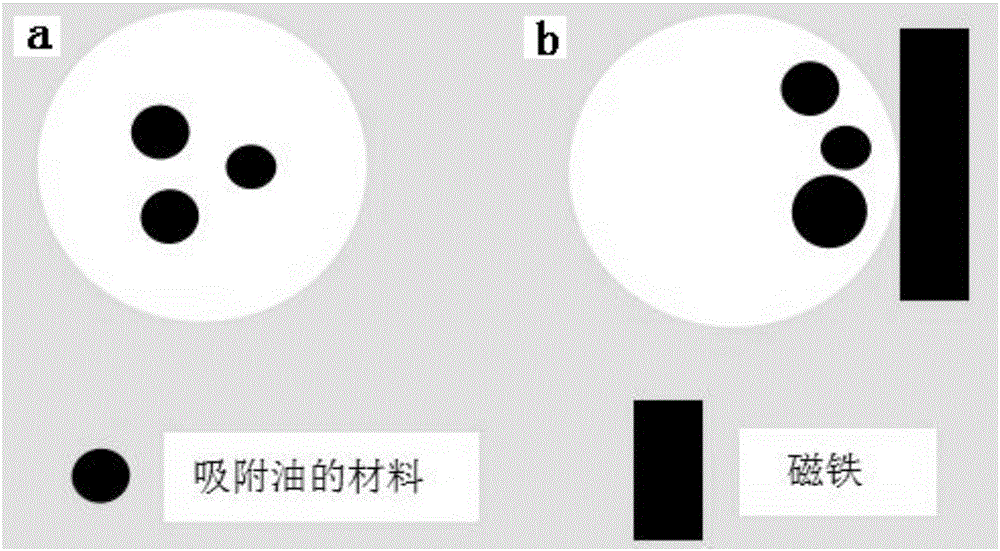

[0050] Characterization and functional identification of the magnetic nano-oil-a...

Embodiment 3

[0055] This embodiment discloses a method for preparing a magnetic nano oil-absorbing material, comprising the following steps:

[0056] 1) Mix the raw materials according to the following weight ratio:

[0057]

[0058] 2) Put the mixed solution in an aerosol sprayer, spray small droplets driven by an inert gas carrier gas, enter a tube furnace for heating and react, the temperature of the tube furnace is 800-1000 degrees Celsius, and the reaction time is 4s~10s.

[0059] 3) Filtrating the material obtained from the reaction in step 2) through a membrane filter to obtain the magnetic nano oil-absorbing material.

[0060] The water-soluble sugar is fructose; the water-soluble iron salt is ferrous nitrate aqueous complex; the carrier gas is an inert gas.

[0061] Characterization and functional identification of the magnetic nano-oil-absorbing material prepared in this example:

[0062] The surface morphology of the magnetic nano-oil-absorbing material prepared in this ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com