CeVO4 mimic enzyme material, and preparation method thereof and application

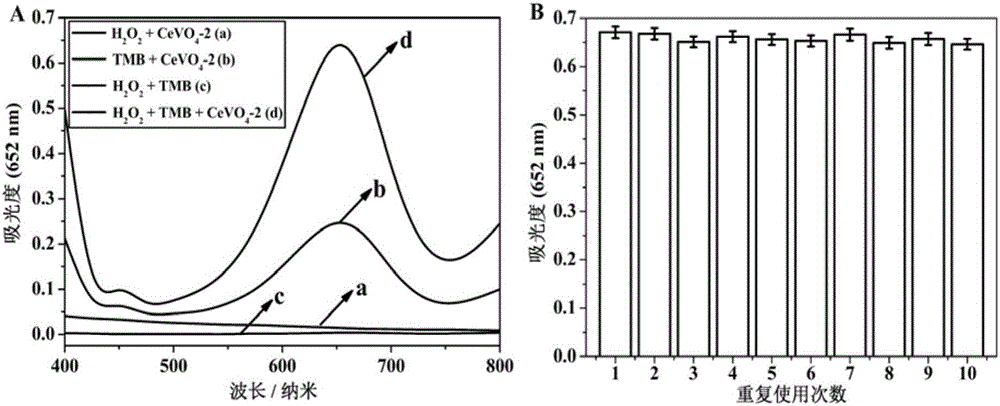

A technology of imitating enzymes and H2O2, applied in the field of imitating enzymes, can solve the problems of unexploited application potential in the biological field, and achieve the effects of good imitation peroxidase catalytic performance, easy control, stability and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

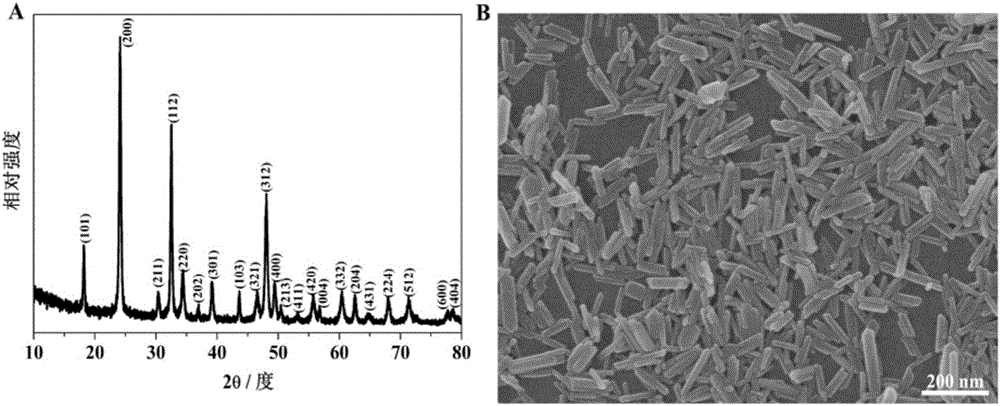

[0022] Example 1 Rod CeVO 4 preparation of

[0023] 1.6mmolCe(NO 3 ) 3 ·6H 2 O and 2.0mmol ethylenediaminetetraacetic acid disodium (EDTA) were successively added to 30mL ultrapure water, and magnetically stirred to dissolve it to obtain solution A; meanwhile, 1.6mmol NH 4 VO 3 Add it into 30mL of ultrapure water, heat to 80°C and magnetically stir to dissolve it to obtain solution B; then add the above solution B dropwise to the above solution A under magnetic stirring to obtain a suspension, and then use 2.0mol / L NaOH solution to adjust the pH of the suspension to 10, then transfer the suspension to a stainless steel high-pressure reactor equipped with a polytetrafluoroethylene liner, and put it into an electric constant temperature blast drying oven for heat treatment at 180°C for 24h; After the end, the reactor was cooled to room temperature, and the precipitate obtained by suction filtration was washed with ultrapure water and absolute ethanol several times in sequen...

Embodiment 2

[0025] Example 2 Rod CeVO 4 preparation of

[0026] Prepared by hydrothermal synthesis, the difference from Example 1 is that the amount of EDTA is changed. 1.6mmolCe(NO 3 ) 3 ·6H 2 O and 1.5mmol disodium ethylenediaminetetraacetic acid (EDTA) were successively added to 30mL ultrapure water, and magnetically stirred to dissolve it to obtain solution A; simultaneously, 1.6mmol NH 4 VO 3 Add it into 30mL of ultrapure water, heat to 80°C and magnetically stir to dissolve it to obtain solution B; then add the above solution B dropwise to the above solution A under magnetic stirring to obtain a suspension, and then use 4.0mol / L NaOH solution to adjust the pH of the suspension to 10, then transfer the suspension to a stainless steel high-pressure reactor equipped with a polytetrafluoroethylene liner, and put it into an electric constant temperature blast drying oven for heat treatment at 180°C for 24h; After the end, the reactor was cooled to room temperature, and the precipit...

Embodiment 3

[0027] Prepared by hydrothermal synthesis method, the difference from Example 1 is that the pH value of the suspension is adjusted to 9. 1.6mmolCe(NO 3 ) 3 ·6H 2 O and 2.0mmol disodium ethylenediaminetetraacetic acid (EDTA) were successively added to 30mL ultrapure water, and magnetically stirred to dissolve it to obtain solution A; meanwhile, 2.0mmol NH 4 VO 3 Add it into 30mL of ultrapure water, heat to 80°C and magnetically stir to dissolve it to obtain solution B; then add the above solution B dropwise to the above solution A under magnetic stirring to obtain a suspension, and then use 3.0mol / L NaOH solution to adjust the pH of the suspension to 9, then transfer the suspension to a stainless steel high-pressure reactor equipped with polytetrafluoroethylene lining, and put it into an electric constant temperature blast drying oven for heat treatment at 180°C for 16h; After the end, the reactor was cooled to room temperature, and the precipitate obtained by suction filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com