Method for preparing Mn-Ce/Al2O3 catalyst and catalyzing ozonized organic wastewater difficult to degrade

A catalyst and ozonation technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, heterogeneous catalyst chemical elements, etc., can solve the problem of incomplete research on catalytic ozonation, and achieve The effect of strengthening the load effect, improving the effect, and increasing the load uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

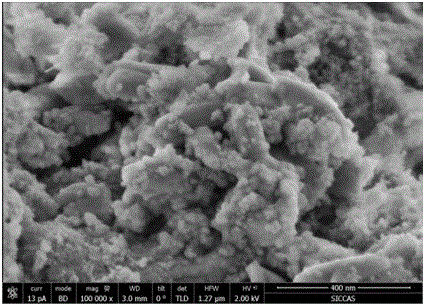

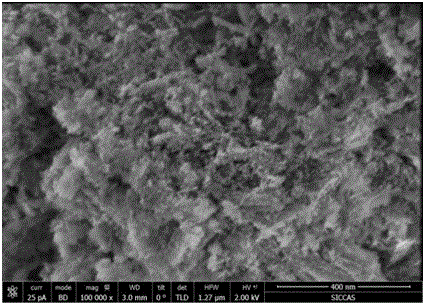

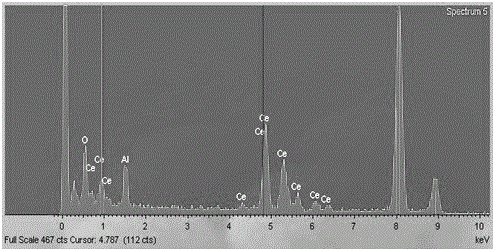

Image

Examples

preparation example Construction

[0035] (2) Preparation of catalyst: Mn-Ce / Al 2 o 3 Composite metal oxides are prepared by impregnation precipitation, including the following steps:

[0036] Step 1. According to the optimum concentration of the cerium impregnating solution determined by previous experiments, it is 0.7mol / L. According to the molar ratio of manganese and cerium of 0.2-1, weigh an appropriate amount of metal salt, dissolve it in an appropriate amount of water, and stir to make it dissolve uniformly. Add a certain amount of carrier Al to the water bath environment at -55°C 2 o 3 , the weight ratio of the carrier to the impregnation solution is 1:5, and the impregnation is carried out at a constant temperature for 12-24 hours;

[0037] Step 2. Take an appropriate amount of precipitating agent (sodium hydroxide solution), and slowly add it dropwise to the solution of the mixed salt obtained in the above step 1;

[0038] Step 3, separate by suction filtration, wash 2-4 times with deionized water...

Embodiment 1

[0061] Embodiment 1: a kind of Mn-Ce / Al 2 o 3 The method for removing phenol wastewater by catalyst combined with ozonation comprises the steps of activating the carrier, preparing the catalyst, and removing target wastewater through combined ozonation, including the following specific steps:

[0062] (1) Activation treatment of the carrier: the purchased alumina pellets were washed several times with deionized water, and dried in an oven at 110°C;

[0063] (2) Preparation of catalyst: Mn-Ce / Al 2 o 3 Composite metal oxides are prepared by impregnation precipitation, including the following steps:

[0064] Step 1. Weigh 1.2527g of manganese salt and 15.1942g of cerium salt according to the molar ratio of Mn:Ce=0.2, mix them and dissolve them in water, stir to make them dissolve uniformly, and form 50ml of impregnating solution. Add 10g carrier Al 2 o 3 , soaking at constant temperature for 12-24h.

[0065] Step 2, measure precipitating agent sodium hydroxide 23.8g and be...

Embodiment 2

[0070] Embodiment 2: a kind of Mn-Ce / Al 2 o 3 The method for removing phenol wastewater by catalyst combined with ozonation comprises the steps of activating the carrier, preparing the catalyst, and removing target wastewater through combined ozonation, including the following specific steps:

[0071] (2) Preparation of catalyst: Mn-Ce / Al 2 o 3 Composite metal oxides are prepared by impregnation precipitation, including the following steps:

[0072] Step 1. Weigh 6.2633g of manganese salt and 15.1942g of cerium salt according to the molar ratio of Mn:Ce=1, mix and dissolve in water, stir to make it dissolve uniformly, form 50ml of impregnating solution, add in water bath environment of 40-55℃ 10g carrier Al 2 o 3 , soaking at constant temperature for 12-24h. .

[0073] Step 2, measure precipitating agent sodium hydroxide 35g and be made into solution and slowly add in the solution of the mixed salt that above-mentioned step 1 obtains;

[0074] Step 3, separate by sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com