Paper and plastic separation technology of waste paper aluminum plastic composite packaging materials

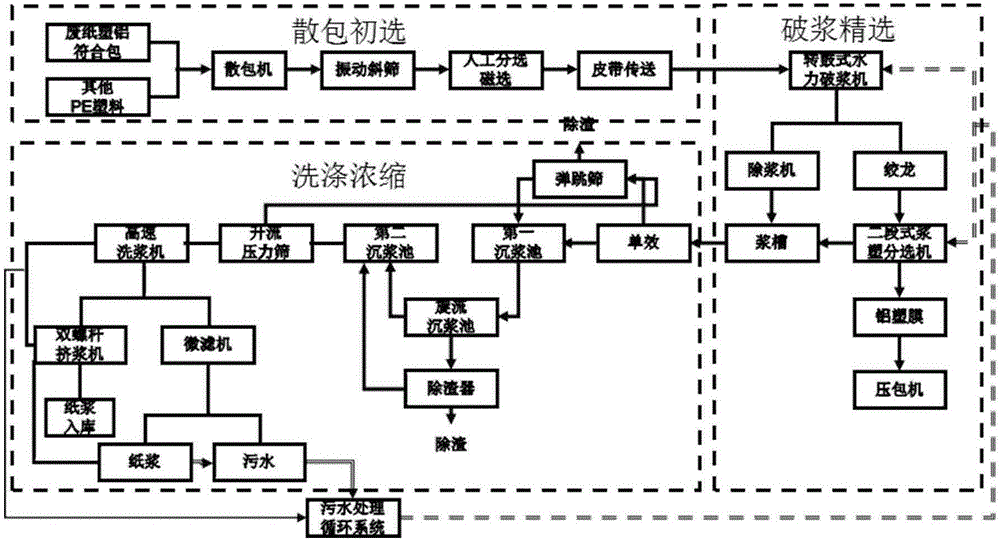

A composite packaging material, paper-plastic separation technology, applied in the direction of solid separation, plastic recycling, mechanical material recycling, etc., can solve the problems of insufficient recycling of products, low product purity, and insufficient separation, and achieve high recycling rate , Improve recycling rate, save cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0016] Implementation case: Xiamen Luhai Environmental Protection Co., Ltd. The daily processing capacity of raw materials in the paper-plastic separation process is 200t / day (wet weight, moisture content about 40%), and the current moisture content of the produced aluminum-plastic film is <50%; the pulp output is 24t / day (moisture content: about 68%, Equivalent dry weight of about 4t).

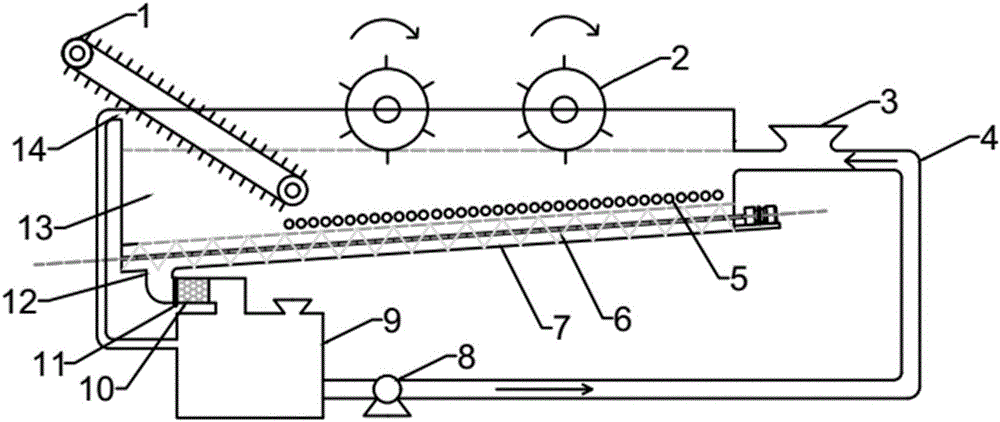

[0017] Such as figure 1 As shown, a paper, aluminum and plastic waste slag separation device according to the present invention mainly includes a material feeding module, a flotation module, a material removal and slag removal module, and an overflow circulation module.

[0018] 1) The feeding and mixing module is mainly composed of main components such as the water inlet pipe 4, the feed port 3, and the propeller 2 (2 groups). The water inlet pipe sends the water body into the flotation tank through the water pump outside the reservoir In 13, the feed port 3 is set above the water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com